Energy Conservation Potentials for Manufacturing of Basic Metal : A Case Study of Steel Wire Industry

Main Article Content

Abstract

his article refers to energy conservation potentials for manufacturing of basic Metal. A study of energy consumption of steel wire factory in the central region of Thailand. The electrical energy of 387,018 kilowatt-hours per year or 1,227,969.41 Bath per year is mainly used in the processes which includes some heating energy. This heat energy is derived form fuel oil of zinc-containing furnace, which uses 75,000 liters of fuel oil per year or 1,007,940 Bath per year. After detailed audit, we found that five measures can be used to improve energy efficiency. These five measures for electrical energy can reduce the energy consumption of 32,518.09 kilowatt-hours per year or 160,314.18 Bath per year. In terms of measures to conserve energy, heat has not been implemented. This is in the process of updating the device. The investment is about 144,640 Bath.

Article Details

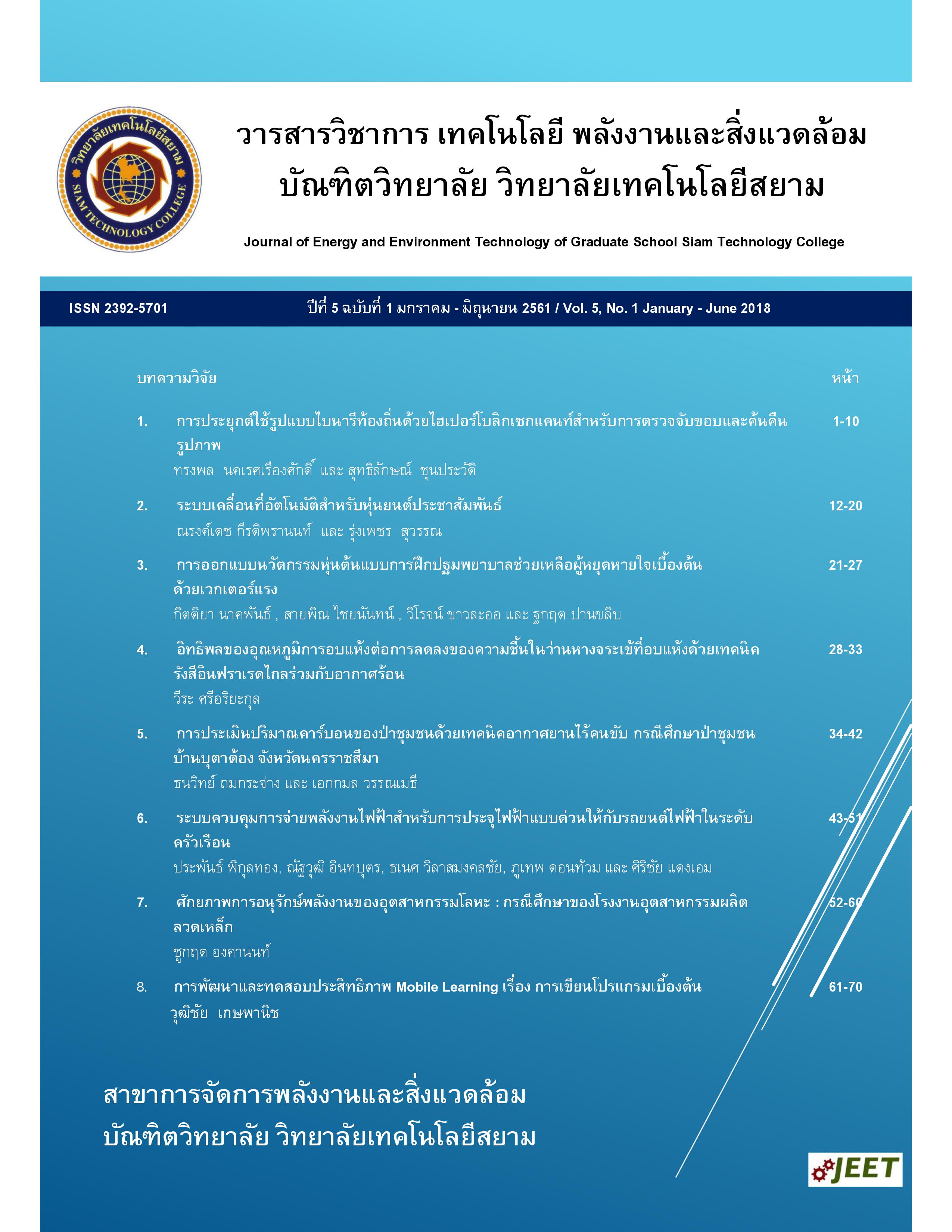

เนื้อหาและข่อมูลในบทความที่ลงตีพิมพ์ในวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม ถือเป็นข้อคิดเห็นและความรับผิดชอบของผู้เขียนบทความโดยตรง ซึ่งกองบรรณาธิการวารสารไม่จำเป็นต้องเห็นด้วย หรือว่าร่วมรับผิดชอบใด ๆ

บทความ ข้อมูล เนื้อหา รูปภาพ ฯลฯ ที่ได้รับการตีพิมพ์ในวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม ถือเป็นลิขสิทธิ์ของวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม หากบุคคล หรือหน่วยงานใดต้องการนำทั้งหมด หรือส่วนหนึ่งส่วนใดไปเผยแพร่ต่อ หรือเพื่อกระทำการใด ๆ จะต้องได้รับอนุญาต เป็นลายลักษณ์อักษรจากวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม เท่านั้น