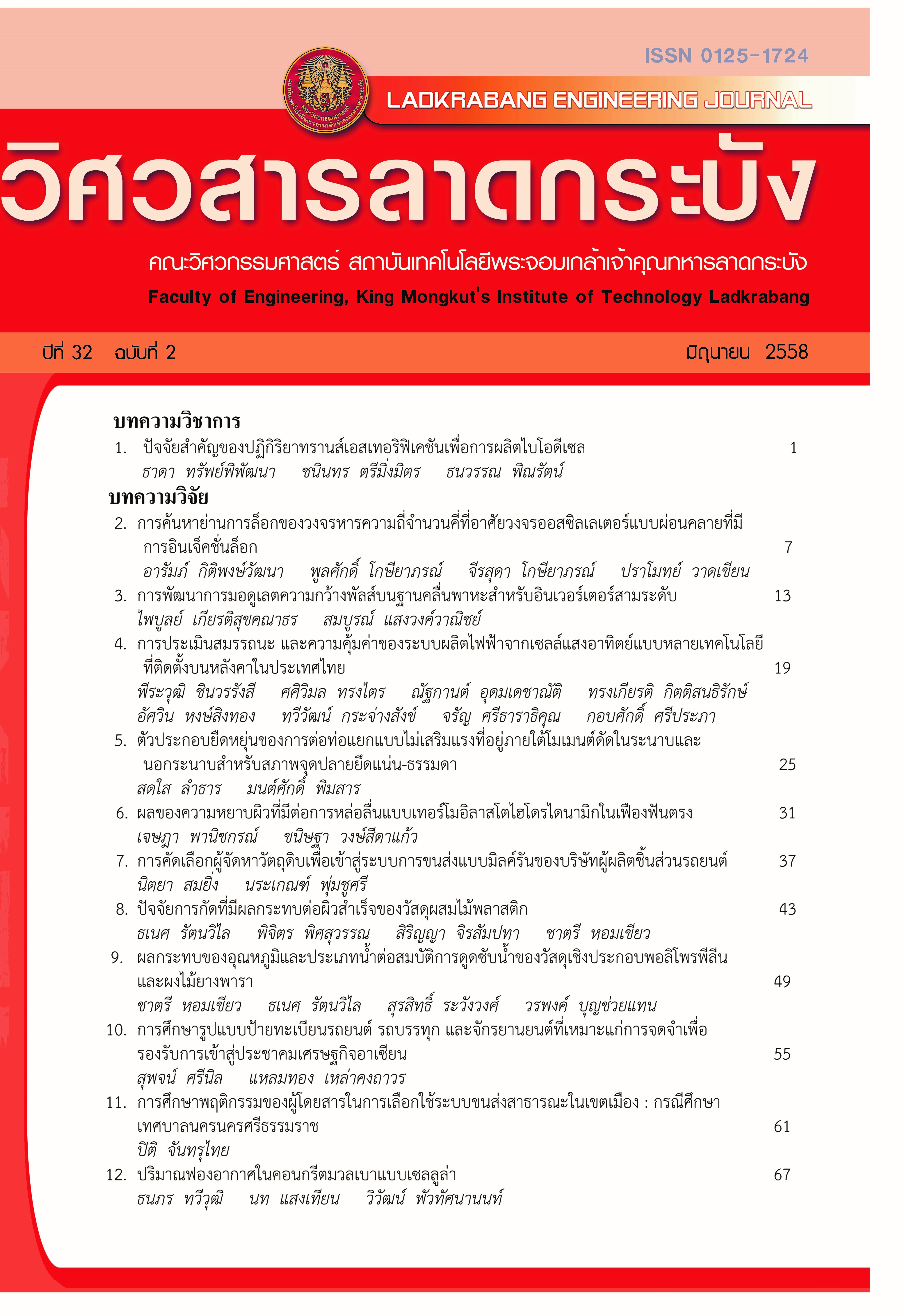

Effects of Surface Roughness on Thermo-Elastohydrodynamic Lubrication in Spur Gear

Abstract

This paper presents the effect of surface roughness to performance characteristics of transient thermal-elastohydrodynamic lubrication (TEHL) in line contact with Newtonian fluids. The time-dependent modified Reynolds equation, energy equation, elasticity equation, viscosity equation and density equation with initial conditions were solved numerically using finite different method, Newton-Raphson method and multigrid multilevel method for an involute spur gear to obtain the film pressure profiles, film thickness profiles and traction coefficient in the contact region. The results show that surface roughness has significant affected on film pressure, film thickness, film temperature and friction coefficient. The film thickness reaches its minimum at approach point. When the line of action increases film thickness increases. The film temperature and friction coefficient were suddenly increase when the transition from two pairs to one pair and vice versa are modeled as a step variation of load. The minimum friction coefficient and film temperature were occurrence at pitch point.

References

[2] R.Larsson,“Transient non-Newtonion elastohydro-dynamic lubrication analysis of an involute spur gear”, Wear, Vol. 207, pp 67-73, 1997.

[3] M. Al-Samieh and H. Rahnejat, “Ultra-Thin Lubri-cating Films Under Transient Conditions”, Journal Physics D:Applied Physics, vol.34, pp. 2610-2621, 2001.

[4] Y. Wang, H. Li, J. Tong and P. Yang, “Transient thermoelastohydrodynamic lubrication analysis of an involute spur gear”, Tribology International Vol. 37, pp 773-782, 2004.

[5] G. Guangteng, P.M. Cann, A.V. Olver and H.A. Spikes, “An experimental study of film thickness between rough surfaces in EHD contacts”, Tribology International, Vol 33 pp 183-189, 2000.

[6] K. Wongseedakeaw, “Performance Charac-teristics of Elastohydrodynamic Lubrication in Spur Gear with non-Newtonian Lubricant”,Ladkrabang Engineering Journal, Vol. 27, No. 4, pp.43-48, 2010.

[7] K. Wongseedakeaw, “The Effect of Surface Roughness to Elastohydrodynamic Lubrication in Spur Gear with non-Newtonian Lubricant”, KKU Engineering Journal, Vol.38 No.1, pp 43-52, 2011.

[8] A.A. Lubrecht, W.E. ten Napel and R. Bosma, “Multigrid an Alternative Method for Calculating Film Thickness and Pressure Profiles in Elastohydrodynamically Lubri-cated Line Contacts”, ASME Journal of Tribology, 108, 1986, pp. 551-556.

[9] A. Francisco, J. Frene and A. Blouin, “Multilevel Solution to Elastohydrodynamic Contact for the Water Lubricated 3D Line Contact”, STLE Tribology Transactions, 45, 2002, pp. 110-116.

[10] J.W. Carslaw and J.C. Jaeger, “Conduction of Heat in Solids”, Oxford University Press, 1959, London.

[11] C.J.A. Roelands, “Correlational Aspects of the Viscosity-Temperature-Pressure Relationship of Lubricating Oils”, Druk, V.R.B., Groingen, 1996, Netherland.

[12] S. Wang, C. Cusano and T.F. Conry, “Thermal analysis of elastohydrodynamic lubrication of line contact using the Ree-Eyring fluid model”, Journal of Tribology, 113, 1991, pp. 232-244.

Downloads

Published

How to Cite

Issue

Section

License

The published articles are copyrighted by the School of Engineering, King Mongkut's Institute of Technology Ladkrabang.

The statements contained in each article in this academic journal are the personal opinions of each author and are not related to King Mongkut's Institute of Technology Ladkrabang and other faculty members in the institute.

Responsibility for all elements of each article belongs to each author; If there are any mistakes, each author is solely responsible for his own articles.