A genetic-neural optimization approach for friction stir spot welding of semi-solid metal Aluminum Alloy 5083

Main Article Content

Abstract

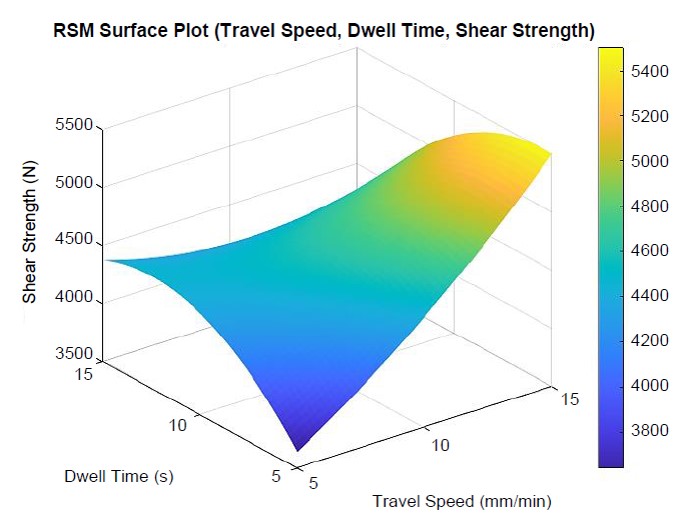

Friction Stir Spot Welding (FSSW) of Semi-Solid Metal (SSM) Aluminum Alloy 5083 poses challenges due to nonlinear interactions between process parameters and mechanical properties. Traditional optimization methods, such as Response Surface Methodology (RSM), provide statistical modeling but often fail to capture these complexities accurately. This study integrates Artificial Neural Networks (ANNs) with Genetic Algorithms (GAs) and Response Surface Methodology (RSM) to develop a hybrid optimization framework for FSSW parameter selection, aiming to enhance weld strength and hardness while minimizing the number of experimental trials. The ANN model, trained using a feed-forward backpropagation algorithm with the Levenberg-Marquardt learning rule, predicts tensile shear strength and weld hardness based on key parameters: rotational speed, travel speed, and dwell time. GA optimizes these parameters through an evolutionary search, while RSM validates the results and assesses parameter interactions. The optimized parameters 2143.93 RPM, 14.33 mm/min, and 6.58 s yield a shear strength of 5999.99 N. ANN exhibited lower mean absolute error (MAE) and root mean squared error (RMSE) than RSM, confirming superior predictive capability. However, RSM provided statistical validation, ensuring robust insights. The findings highlight the effectiveness of AI-driven optimization in welding applications, reducing experimental trials while ensuring optimal mechanical performance. Future research should explore the integration of deep learning and real-time sensor feedback for further enhancement.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Jo DS, Kahhal P, Kim JH. Optimization of friction stir spot welding process using bonding criterion and artificial neural network. Materials. 2023;16(10):3757.

Pookamnerd Y, Thosa P, Charonerat S, Prasomthong S. Development of mechanical property prediction model and optimization for dissimilar aluminum alloy joints with the friction stir welding (FSW) process. EUREKA Phys Eng. 2023;3:112-28.

Kraiklang R, Chueadee C, Jirasirilerd G, Sirirak W, Gonwirat S. A multiple response prediction model for dissimilar AA-5083 and AA-6061 friction stir welding using a combination of AMIS and machine learning. Computation. 2023;11(5):100.

Cho M, Gim J, Kim JH, Kang S. Development of an artificial neural network model to predict the tensile strength of friction stir welding of dissimilar materials using cryogenic processes. Appl Sci. 2024;14(20):9309.

Prasomthong S, Kaewchaloon A, Charonerat S. Optimization of friction stir spot welding between aluminium alloys and titanium alloy by the Taguchi method. SNRU J Sci Technol. 2022;14(3):245169.

Raj A, Kumar JP, Rego AM, Rout IS. Optimization of friction stir welding parameters during joining of AA3103 and AA7075 aluminium alloys using Taguchi method. Mater Today Proc. 2021;46:7733-9.

Sivam SPSS, Balasubramanian S, Gurumani A, Kesavan S. Prediction of friction stir welding in aluminium 6061–T6 using ANN. Mater Today Proc. 2022;68:2342-7.

Vangalapati M, Balaji K, Gopichand A. ANN modeling and analysis of friction welded AA6061 aluminum alloy. Mater Today Proc. 2019;18:3357-64.

Siamakmanesh N, Mostafaei MA. A novel approach to investigate the effect of friction stir welding parameters on hardness and grain size of pure titanium using artificial neural network. Mater Today Commun. 2024;38:108404.

Bharti S, Kumar S, Singh I, Kumar D, Bhurat SS, Abdullah MR, et al. A review of recent developments in friction stir welding for various industrial applications. J Mar Sci Eng. 2024;12(1):71.

Gibson BT, Lammlein DH, Prater TJ, Longhurst WR, Cox CD, Ballun MC, et al. Friction stir welding: process, automation, and control. J Manuf Process. 2013;16(1):56-73.

Zhang B, Chen X, Pan K, Wang J. Multi-objective optimization of friction stir spot-welded parameters on aluminum alloy sheets based on automotive joint loads. Metals. 2019;9(5):520.

Tamjidy M, Baharudin BTHT, Paslar S, Matori KA, Sulaiman S, Fadaeifard F. Multi-objective optimization of friction stir welding process parameters of AA6061-T6 and AA7075-T6 using a biogeography based optimization algorithm. Materials. 2017;10(5):533.

Nejad RM, Sina N, Moghadam DG, Branco R, Macek W, Berto F. Artificial neural network based fatigue life assessment of friction stir welding AA2024-T351 aluminum alloy and multi-objective optimization of welding parameters. Int J Fatigue. 2022;160:106840.

Shunmugasundaram M, Kumar AP, Sankar LP, Sivasankar S. Optimization of process parameters of friction stir welded dissimilar AA6063 and AA5052 aluminum alloys by Taguchi technique. Mater Today Proc. 2020;27:871-6.

Senapati NP, Panda DK, Bhoi RK. Prediction of multiple characteristics of friction-stir welded joints by Levenberg–Marquardt algorithm-based artificial neural network. Mater Today Proc. 2021;41:391-6.

Atharifar H. Optimum parameters design for friction stir spot welding using a genetically optimized neural network system. Proc Inst Mech Eng B: J Eng Manuf. 2009;224(3):403-18.

Suresh S, Elango N, Venkatesan K, Lim WH, Palanikumar K, Rajesh S. Sustainable friction stir spot welding of 6061-T6 aluminium alloy using improved non-dominated sorting teaching learning algorithm. J Mater Res Technol. 2020;9(5):11650-74.

Sabry I, El-Zathry NE, Gadallah N, Ghafaar MA. Implementation of hybrid RSM-GA optimization techniques in underwater friction stir welding. J Phys Conf Ser. 2022;2299(1):012014.

Elsheikh AH, Elmiligy M, El-Kassas AM. Optimization of joint strength in friction stir welded wood plastic composites using ANFIS and Cheetah Optimizer. J Mater Res Technol. 2025;34:2539-52.

Li J, Dong H, Tang Z, Li P, Wu B, Ma Y, et al. Influence of surface pretreatment on the bonding mechanism and mechanical properties of AA5052/CFRP friction stir spot welded joint. J Manuf Process. 2023;105:112-23.

Suryanarayanan R, Sridhar VG. Optimizing the process parameters in friction stir spot welding of dissimilar aluminum alloys using genetic algorithm. IOP Conf Ser Mater Sci Eng. 2021;1123(1):012027.

Rahiman MK, Santhoshkumar S, Mythili S, Barkavi GE, Velmurugan G, Sundarakannan R. Experimental analysis of friction stir welded of dissimilar aluminium 6061 and Titanium TC4 alloys using Response Surface Methodology (RSM). Mater Today Proc. 2022;66:1016-22.

Patel MB, Dave KG. Genetic algorithm based optimization of friction stir welding process parameters on AA7108. Int J Innov Technol Explor Eng. 2021;10(8):47-53.

Bîrsan DC, Păunoiu V, Teodor VG. Neural networks applied for predictive parameters analysis of the refill friction stir spot welding process of 6061-T6 aluminum alloy plates. Materials. 2023;16(13):4519.

Janga VSR, Awang M, Sallih N, Lemma TA. Thermo-mechanical and material flow characteristics of tool sequencing dynamics in refill FSSW of thin Alclad AA7075-T6 sheets: numerical analysis using meshless smoothed-particle hydrodynamics method. J Adv Join Process. 2025;11:100285.

Zhou T, He L, Zou Z, Du F, Wu J, Tian P. Three-dimensional turning force prediction based on hybrid finite element and predictive machining theory considering edge radius and nose radius. J Manuf Process. 2020;58:1304-17.

Zou JL, Wu SK, Xiao RS, Li F. Effects of a paraxial TIG arc on high-power fiber laser welding. Mater Des. 2015;86:321-7.

Colmenero AN, Orozco MS, Macías EJ, Fernández JB, Muro JCSD, Fals HC, et al. Optimization of friction stir spot welding process parameters for Al-Cu dissimilar joints using the energy of the vibration signals. Int J Adv Manuf Technol. 2019;100(9-12):2795-802.

Naik P, Pradhan S, Sahoo P, Acharya SK. Study of mechanical behaviour of raw and chemical treated bio-filler composites and its effect on moisture absorption. Mater Today Proc. 2020;26:1936-40.

Van AL, Nguyen TT. Optimization of friction stir welding operation using optimal Taguchi-based ANFIS and genetic algorithm. Stroj Vestn J Mech Eng. 2022;68(6):424-38.

Mothilal M, Kumar A. Optimization of friction stir welding process parameter in the joining of AA7075-T6/AA5083-O dissimilar aluminum alloy using response surface methodology. Int J Press Vessels Pip. 2024;211:105282.

Sreenivasan KS, Kumar SS, Katiravan J. Genetic algorithm based optimization of friction welding process parameters on AA7075-SiC composite. Eng Sci Technol Int J. 2019;22(4):1136-48.

Meengam C, Dunyakul Y, Kuntongkum S. A study of the essential parameters of friction-stir spot welding that affect the D/W ratio of SSM6061 aluminum alloy. Materials. 2023;16(1):85.

Yan Y, Shen Y, Zhang W, Hou W. Friction stir spot welding ABS using triflute-pin tool: effect of process parameters on joint morphology, dimension and mechanical property. J Manuf Process. 2018;32:269-79.

Khalafe WH, Sheng EL, Bin Isa MR, Omran AB, Shamsudin SB. The effect of friction stir welding parameters on the weldability of aluminum alloys with similar and dissimilar metals: review. Metals. 2022;12(12):2099.

Saravanakumar K, Kumar MRP, Suruthi GY, Vignesh KS, Nithishkumar T, Amirtharaj MV. Optimization of friction stir welding process parameters for weld strength of Inconel 625 parts using genetic algorithm. Mater Today Proc. 2024;98:127-34.

Silva BH, Zepon G, Bolfarini C, Santos JFD. Refill friction stir spot welding of AA6082-T6 alloy: hook defect formation and its influence on the mechanical properties and fracture behavior. Mater Sci Eng A. 2020;773:138724.

Xiong J, Peng X, Shi J, Wang Y, Sun J, Liu X, et al. Numerical simulation of thermal cycle and void closing during friction stir spot welding of AA-2524 at different rotational speeds. Mater Charact. 2021;174:110984.

Nasir T, Asmael M, Zeeshan Q, Solyali D. Applications of machine learning to friction stir welding process optimization. Jurnal Kejuruteraan. 2020;32(1):171-86.

Kahhal P, Ghasemi M, Kashfi M, Ghorbani-Menghari H, Kim JH. A multi-objective optimization using response surface model coupled with particle swarm algorithm on FSW process parameters. Sci Rep. 2022;12(1):2837.

Suryanarayanan R, Sridhar VG. Effect of process parameters in pinless friction stir spot welding of AL 5754–AL 6061 alloys. Metallogr Microstruct Anal. 2020;9(2):261-72.

Correia DS, Gonçalves CV, da Cunha SS, Ferraresi VA. Comparison between genetic algorithms and response surface methodology in GMAW welding optimization. J Mater Process Technol. 2005;160(1):70-6.

Lakshminarayanan AK, Balasubramanian V. Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminium alloy joints. Trans Nonferrous Met Soc China. 2009;19(1):9-18.

Math P, Kumar BSP. Analysis, optimization and modelling of CO₂ welding process parameters in fabrication of mild steel plates. Mater Today Proc. 2021;45:420-3.

Ahmed S, Rahman RA, Awan A, Ahmad S, Akram W, Amjad M, et al. Optimization of process parameters in friction stir welding of aluminum 5451 in marine applications. J Mar Sci Eng. 2022;10(10):1539.