Enhanced biogas production through co-digestion of tapioca starch wastewater and duckweed in a continuous stirred tank reactor

Main Article Content

Abstract

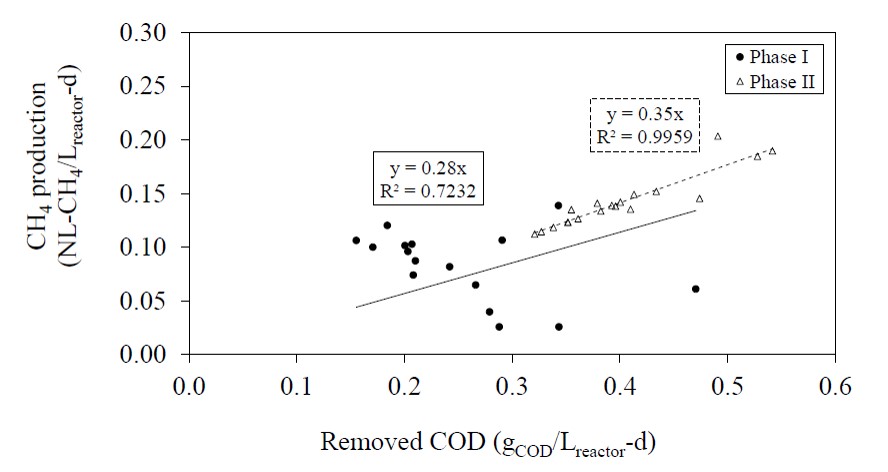

This study investigates the biogas production performance of co-digesting duckweed with tapioca starch wastewater (TSW) in a laboratory-scale continuous stirred tank reactor (CSTR). Duckweed, with its rich nutrient composition, represents an underutilized biomass resource for renewable energy production in Thailand, where the tapioca starch industry constitutes a significant economic sector. The experimental setup utilized a 3-liter CSTR operated at mesophilic conditions (35°C) with a hydraulic retention time (HRT) of 28 days. Initial mono-digestion of TSW at an organic loading rate (OLR) of 0.31 gCOD/L-d resulted in a specific methane production of 0.28 NL-CH4/g COD removed (NL = liter of gas at 273 K and 1 atm). Subsequent co-digestion with duckweed (1.0 g dry weight per liter of TSW) under identical operational conditions, enhanced methane production to 0.35 NL CH₄/g COD removed—corresponding to a 1.3-fold increase in specific methane production yield. These findings demonstrate that co-digestion of duckweed with TSW significantly enhances methane yield compared to mono-digestion of TSW, offering a promising approach for simultaneous wastewater treatment and renewable energy generation in Thailand's tapioca processing industry.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Yang J, Hu S, Li G, Khan S, Kumar S, Yao L, et al. Transformation development in duckweeds. In: Cao X, Fourounjian P, Wang W, editors. Compendium of plant genomes. Cham: Springer; 2020. p. 143-55.

Pagliuso D, Grandis A, Fortirer JS, Camargo P, Floh EIS, Buckeridge MS. Duckweeds as promising food feedstocks globally. Agronomy. 2022;12(4):796.

Koley A, Mukhopadhyay P, Gupta N, Singh A, Ghosh A, Show BK, et al. Biogas production potential of aquatic weeds as the next-generation feedstock for bioenergy production: a review. Environ Sci Pollut Res. 2023;30(52):111802-32.

Dima AD, Pârvulescu OC, Mateescu C, Dobre T. Optimization of substrate composition in anaerobic co-digestion of agricultural waste using central composite design. Biomass Bioenergy. 2020;138:105602.

Sowcharoensuk C. Industry Outlook 2024-2026: Cassava Industry [Internet]. Bangkok: Krungsri Research; 2024 [cited 2025 Feb 5]. Available from: https://www.krungsri.com/en/research/industry/industry-outlook/agriculture/cassava/io/cassava-2024-2026.

Department of Alternative Energy Development and Efficiency. Alternative Energy Development Plan 2018-2037 (AEDP2018). Bangkok: Ministry of Energy; 2020. (In Thai)

Toyama T, Hanaoka T, Tanaka Y, Morikawa M, Mori K. Comprehensive evaluation of nitrogen removal rate and biomass, ethanol, and methane production yields by combination of four major duckweeds and three types of wastewater effluent. Bioresour Technol. 2018;250:464-73.

Kotamraju A, Logan M, Lens PNL. Integrated bioprocess for Se(VI) remediation using duckweed: coupling selenate removal to biogas production. J Hazard Mater. 2023;459:132134.

Ardhana ZM. Evaluation of methane production potential from Spirodela Polyrhiza and tapioca starch factory wastewater as co-substrates [thesis]. Khon Kaen: Khon Kaen University; 2023.

National Science and Technology Development Agency (NSTDA). Bio-circular-green economy 2021-2027. Bangkok: National Science and Technology Development Agency; 2022.

Tchobanoglous G, Stensel HD, Tsuchihashi R, Burton F, Abu-Orf M, Bowden G, et al. Wastewater engineering: treatment and resource recovery. 5th ed. New York: McGraw-Hill Education; 2014.

Baird R, Rice EW, Eaton AD. Standard methods for the examination of water and wastewater. Washington: American Water Works Association; 2017.

Sanchez-Ledesma LM, Rodríguez-Victoria JA, Ramírez-Malule H. Acidogenic fermentation of cassava wastewater: effect of the Substrate-to-Microorganism ratio and temperature on volatile fatty acids production. Water. 2024;16(23):3344

de Sousa Rollemberg SL, de Oliveira LQ, de Barros AN, Firmino PIM, dos Santos AB. Pilot-scale aerobic granular sludge in the treatment of municipal wastewater: optimizations in the start-up, methodology of sludge discharge, and evaluation of resource recovery. Bioresour Technol. 2020;311:123467.

Jameel MK, Mustafa MA, Ahmed HS, Mohammed AJ, Ghazy H, Shakir MN, et al. Biogas: production, properties, applications, economic and challenges: A review. Results Chem. 2024;7:101549.

Drosg B, Braun R, Bochmann G, Alsaeidi T. Analysis and characterisation of biogas feedstocks. In: Wellinge A, Murphy J, Baxter D, editors. The biogas handbook: science, production and applications. Cambridge: Woodhead Publishing; 2013. p. 52-84.

Baek G, Saeed M, Choi HK. Duckweeds: their utilization, metabolites and cultivation. Appl Biol Chem. 2021;64(1):73.

Thepubon T, Choeisai P, Mungkarndee P, Choeisai K, Syutsubo K. Effect of suspended solids removal methods on methane production from tapioca starch wastewater. Eng Appl Sci Res. 2020;47(1):87-92.