Durability and mechanical characterization of tapiales with lime and sugar cane fiber

Main Article Content

Abstract

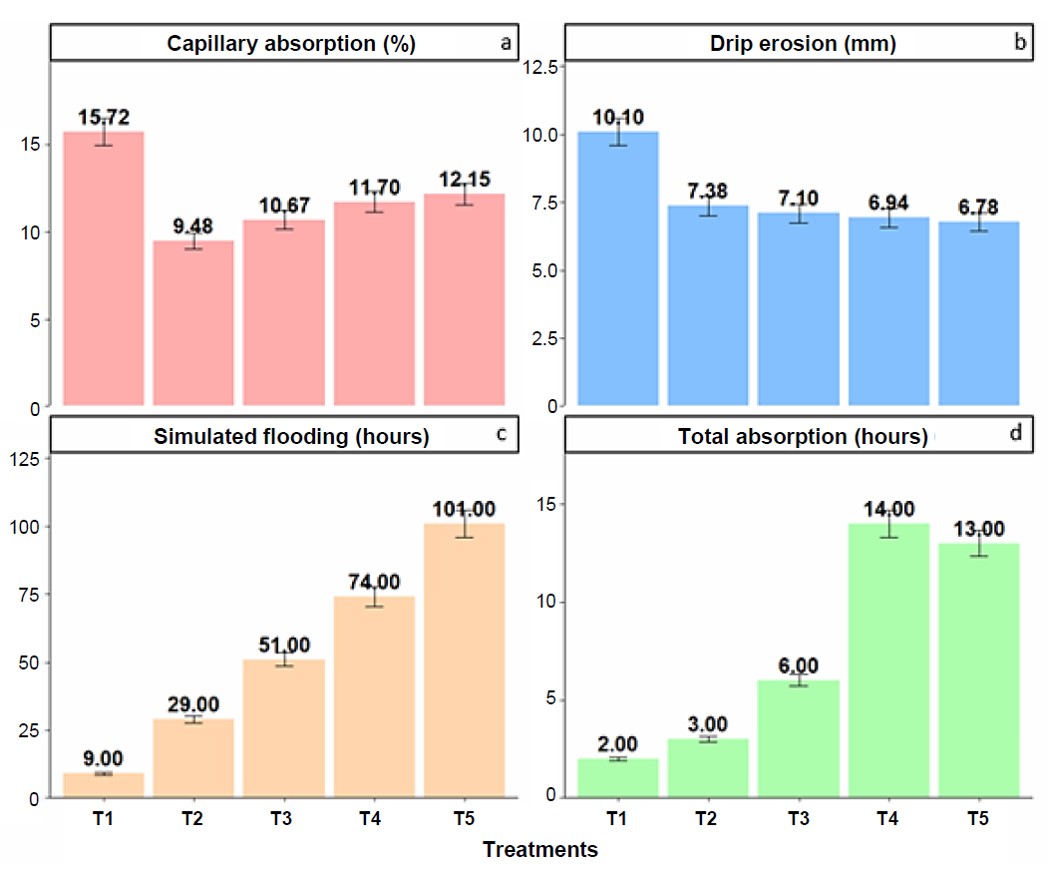

Worldwide, technological advances in construction have transformed construction materials, highlighting earth for its advantages. The traditional rammed earth method combines sustainability, efficiency and the creation of durable and attractive structures. Therefore, the objective of this research was to study the durability and mechanical characterization of rammed earth by adding lime and sugar cane fiber. Using an applied methodology and experimental design, preparing samples with the addition of lime in doses of 5%, 10%, 15%, 20%, obtaining an optimum to combine it with sugar cane fiber in doses of 0.5%, 1%, 1.5% and 2%. The fiber was 40 mm long and was randomly placed in the dry rammed soil mixture. The results indicated that the optimal percentage was 15% lime + 1.5% sugar cane fiber, since adding lime increases its mechanical properties and adding sugar cane fiber helps in durability analysis, improving by 10% compared to the initial samples.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

El bourki A, Koutous A, Hilali E. Fiber-reinforced rammed earth: state of the art and perspectives. Civ Eng Archit. 2023;11(5A):3162-74.

Gil-Martín LM, Fernández-Ruiz MA, Hernández-Montes E. Mechanical characterization and elastic stiffness degradation of unstabilized rammed earth. J Build Eng. 2022;56:104805.

Parlato MCM, Cuomo M, Porto SMC. Natural fibers reinforcement for earthen building components: mechanical performances of a low quality sheep wool (“Valle del Belice” sheep). Constr Build Mater. 2022;326:126855.

Ávila F, Puertas E, Torrus C, Gallego R. Influence of crack propagation on the seismic behavior of historic rammed earth buildings: The Tower of Muhammad in the Alhambra (Spain). Eng Struct. 2024;301:117365.

Zarasvand KA, Narani SS, Siddiqua S. Thermal insulation enhancement of rammed earth using wood fly ash and calcium bentonite. Constr Build Mater. 2023;409:134097.

Widder L. Earth eco-building: textile-reinforced earth block construction. Energy Procedia. 2017;122(14):757-62.

Lima SA, Varum H, Sales A, Neto VF. Analysis of the mechanical properties of compressed earth block masonry using the sugarcane bagasse ash. Constr Build Mater. 2012;35:829-37.

Pan S, Zabed HM, Wei Y, Qi X. Technoeconomic and environmental perspectives of biofuel production from sugarcane bagasse: current status, challenges and future outlook. Ind Crop Prod. 2022;188:115684.

Devadiga DG, Subrahmanya Bhat K. Sugarcane bagasse fiber reinforced composites: recent advances and applications. Cogent Eng. 2020;7(1):1823159.

Loh TR, Sujan D, Rahman ME, Das CA. Sugarcane bagasse—the future composite material: a literature review. Resour Conserv Recycl. 2013;75:14-22.

Chantit F, El Abbassi FE, Kchikach A. Performance of compressed earth bricks reinforced with sugar industrial by-products bagasse and molasse: mechanical, physical and durability properties. J Build Eng. 2024;90:109403.

Paul S, Islam MS, Elahi TE. Comparative effectiveness of fibers in enhancing engineering properties of earth as a building material: a review. Constr Build Mater. 2022;332:127366.

Kumar N, Barbato M. Effects of sugarcane bagasse fibers on the properties of compressed and stabilized earth blocks. Constr Build Mater. 2022;315:125552.

El Maatoufi Y, Nasla S, Jamil Y, Gueraoui K, Cherraj M. Study of the effect of stabilization, by lime and sugarcane fibers, on the physico-mechanical and thermal properties of compressed earth blocks (CEB) used in the construction of a soil from El Gharb in Morocco. JP J Heat Mass Transf. 2022;26:61-80.

Mamani M, Reynaldo E. Comparative analysis of the mechanical properties of fiber-reinforced adobe and conventional adobe, Carabayllo - 2019 [thesis]. Trujillo: Universidad César Vallejo; 2020. (In Spanish)

Quispe Guerrero O. Mechanical characteristics of rammed earth made with sugarcane fibers, Bagua Grande district, Amazonas region in 2018 [thesis]. Trujillo: Universidad César Vallejo; 2019. (In Spanish)

Guettatfi L, Hamouine A, Himouri K, Labbaci B. Mechanical and water durability properties of adobes stabilized with white cement, quicklime and date palm fibers. Int J Archit Herit. 2023;17(4):677-91.

Li Zavaleta BF. Influence of sugarcane bagasse and rice husk on the mechanical properties of adobe, Lambayeque city [thesis]. Chiclayo: Universidad Católica Santo Toribio de Mogrovejo; 2023. (In Spanish)

Carrasco Pacheco DS, Correa Barboza EM, Muñoz Pérez SP, García Chumacero JM, Sánchez Diaz E, Damiani Lazo CA, et al. Influence of rice husk and cabuya fiber on the physical and mechanical properties of adobe. Eng Appl Sci Res. 2025;52(1):112-24.

Muñoz-Pérez SP, Sánchez-Díaz E, Barboza-Culqui D, Garcia-Chumacero JM. Use of recycled concrete and rice husk ash for concrete: a review. J Appl Res Technol. 2024;22:138-55.

Cadenas Alvarado LY, Jacinto Huamanchumo RM, Garcia Chumacero JM, Salinas Vásquez NR, Chavez Cotrina CO. Experimental study of hybrid concrete blocks based on sawdust and calcined clay using cement as a binder. Innov Infrastruct Solut. 2024;9:445.

Muñoz S, Rojas M, Villena L, Tepe V, Garcia J, Alvarez J. Physical and mechanical characterization of cement-stabilized compressed earth bricks. Revista Ingenieria de Construccion. 2024;39(1):85-95.

Burgos Cotrina JA, Cubas Benavides EA, Garcia Chumacero JM. Analysis of the combination of glass and polypropylene fibers on the mechanical properties of mortar. J Build Pathol Rehabil. 2025;10:22.

Garcia Chumacero JM, Acevedo Torres PL, Corcuera La Portilla CC, Muñoz Perez SP, Villena Zapata LI. Effect of the reuse of plastic and metallic fibers on the characteristics of a gravelly soil with clays stabilized with natural hydraulic lime. Innov Infrastruct Solut. 2023;8:185.

García Chumacero JM, Acevedo Torres PL, Corcuera La Portilla CC, Muñoz Perez SP. Influence of artificial intelligence on the optimization of the dosage of natural hydraulic lime, plastic and metallic fibers on the geological characteristics of a treated soil. Revista Ingenieria de Construccion. 2023;38(3):473-84.

Castillo Bacalla FC, García Chumacero JM, Villegas Granados LM. Improvement of adobe brick reinforced with sugarcane bagasse fiber, rice husk, and metal mesh: study in Peru. Innov Infrastruct Solut. 2025;10:161.

García Chumacero JM, Gonzales Macedo JL, Sánchez Castillo DJ. Contribution of agricultural ashes and HDPE as a waste material for a sustainable environment applied to the stabilization of a low plasticity clay soil. Innov Infrastruct Solut. 2024;9:67.

Barreto I, Muñoz S, Garcia J, Sanchez E, Diaz E, Ramos C, et al. Experimental investigation of the use of crushed clay brick on the properties of sustainable mortar. Electron J Struct Eng. 2024;24(3):28-33.

Bereche J, García J. Replacement of fine aggregate with refractory brick residue in concrete exposed to elevated temperatures. Revista Politecnica. 2024;53(2):79-88.

Cabanillas Hernandez G, García Chumacero JM, Villegas Granados LM, Arriola Carrasco GG, Marín Bardales NH. Sustainable use of wood sawdust as a replacement for fine aggregate to improve the properties of concrete: a Peruvian case study. Innov Infrastruct Solut. 2024;9:233.

Chaname J, García J, Arriola G. Improvement of the mechanical properties of structural concrete using microporous ethylene vinyl acetate. Revista Politecnica. 2024;53(2):1726.

Muñoz Pérez SP, Pardo Becerra JM, García Chumacero JM, Sánchez Diaz E, Diaz Ortiz EA, Rodriguez Laffite ED, et al. Evaluation of the physical and mechanical properties of concrete with the incorporation of recycled concrete aggregate. Innov Infrastruct Solut. 2024;9:204.

Ávila F, Puertas E, Gallego R. Mechanical characterization of lime-stabilized rammed earth: lime content and strength development. Constr Build Mater. 2022;350:128871.

Robles Rojo, A. Production of adobe blocks with sugar cane bagasse fibers and nopal aggregate to improve compressive strength and durability [thesis]. Colima: National Technological Institute of Mexico; 2022. (In Spanish)

Cáceres Vásquez KR. Analysis of the mechanical strength of lime-stabilized and compacted adobe for ecological and economic construction in Cajamarca [thesis]. Cajamarca: Universidad Nacional de Cajamarca (UNC); 2020. (In Spanish)

Hoyos Sangay CF. Influence of the plant fiber ICHU on the strength of adobes stabilized with 20% lime [thesis]. Cajamarca: National University of Cajamarca; 2020. (In Spanish)

Tisnado Godoy OO. Evaluation of the physical and mechanical properties of adobe masonry walls with the addition of cabuya fiber, Puno – 2022 [thesis]. Puno: Universidad César Vallejo; 2022. (In Spanish)

Sandoval Alvarado GD. Evaluation of the erosion and resistance of adobe added with coal ash and lime [thesis]. Chiclayo: Universidad Santo Toribio de Mogrovejo; 2021. (In Spanish)

Cardenas Flores BE, Mantilla Perez EP. Compressive and flexural strength of compacted adobe with the addition of lime and cortadera fibers, Cajamarca 2023 [thesis]. Cajamarca: Private University of the North; 2024. (In Spanish)

Chambilla Choquecota LD, Limachi Condori JL. Improvement of adobe to increase its mechanical strength by incorporating totorilla fiber in the town of Yunguyo, Puno [thesis]. Lima: Universidad César Vallejo; 2023. (In Spanish)

Rocca Villalobos FJ. Evaluation of the properties of adobe with the addition of rice husk ash and sugarcane bagasse as stabilizers, Ferreñafe 2020 [thesis]. Lima: Universidad César Vallejo; 2020. (In Spanish)

Samame Guerrero JA. Improving the moisture resistance of adobe using sugarcane bagasse in the Tumán district, Lambayeque [thesis]. Chiclayo: Universidad Señor de Sipán; 2023. (In Spanish)

Llontop Mejia BJ, Santisteban Olaya AJ. Influence of sugarcane bagasse fiber on the microstructure and mechanical strength of adobe [thesis]. Chiclayo: Universidad Señor de Sipán; 2024. (In Spanish)

Dalawai VN, Srikanth L, Srikanth I. Experimental investigations on stabilized mud blocks enriched with steel slag for sustainable construction. In: Laishram B, Tawalare A, editors. Recent Advancements in Civil Engineering. ACE 2020. Lecture Notes in Civil Engineering, vol 172. Singapore: Springer; 2022. p. 185-96.

Contreras Moreto JA, Lozano Quispe J, Zurita Herrera A. Compression and absorption strength of stabilized adobe with confitillo Jaén – Cajamarca [thesis]. Jaen: Universidad Nacional de Jaén; 2019. (In Spanish)

Carrillo De La Cruz YDJ. Mechanical and microstructural properties of adobe integrating sugarcane bagasse and rice straw [thesis]. Chiclayo: Universidad Señor de Sipán; 2024. (In Spanish)

ASTM. ASTM D2487: Standard practice for classification of soils for engineering purposes (unified soil classification system). West Conshohocken: ASTM International; 2018.

ASTM. ASTM D4318: Standard test methods for liquid limit, plastic limit, and plasticity index of soils. West Conshohocken: ASTM International; 2017.

ASTM. ASTM C566: Standard test method for total evaporable moisture content of aggregate by drying. West Conshohocken: ASTM International; 1997.

Cajo Ventura JL, Turpo Briseño A. Profitability at the agro-industrial company Pomalca SAA, 2017-2019. Chiclayo: Cesar Vallejo University; 2023. (In Spanish)

Ministry of housing, construction and sanitation. NORMA E.080: Design and construction with reinforced earth. Lima: National Building Regulations; 2020. (In Spanish)