Enhanced real-time paddy moisture content assessment in pneumatic drying using correction factor

Main Article Content

Abstract

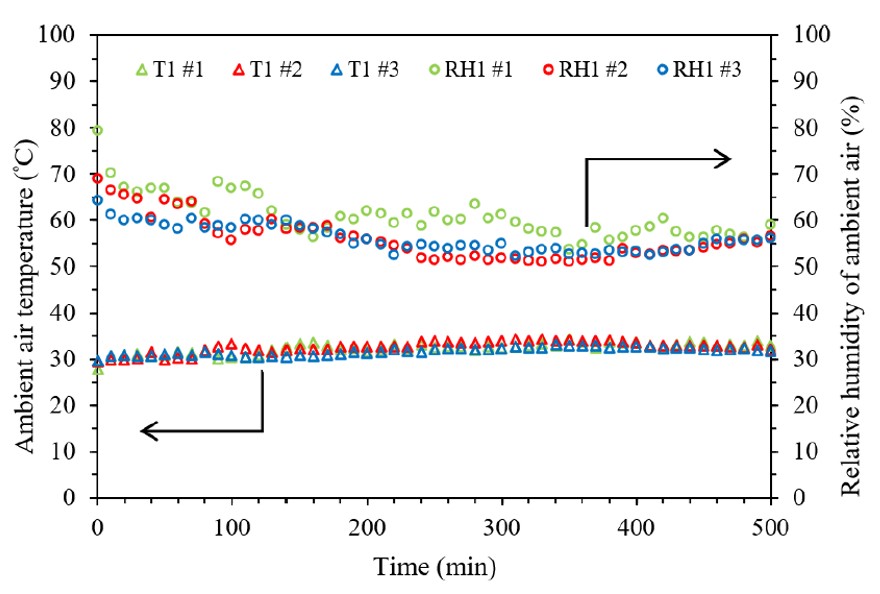

Accurate and real-time monitoring of paddy moisture content during the drying process is critical to preserving rice quality and ensuring efficient post-harvest management. This research article presents the application of weather sensor (DHT22, AM2302, Aosong Electronics Co.,Ltd) that measures air temperature and relative humidity for evaluating paddy moisture content in drying process of a pneumatic dryer. Khao Dawk Mali 105 paddy with initial moisture content of 26%w.b. was dried by a constant drying air temperature of 70 ºC and the drying air flow rate of 0.0631 m3/s with paddy feed rate of 8.45 kg/min throughout the test. Two methods namely DHT-Prediction and DHT-Factor correction methods for evaluating moisture content of paddy were developed by mass balance equation and the result were compared with the reference paddy moisture content analyzed by hot air oven method. The results showed that the DHT-Prediction method gave high moisture measurement error compared to the reference paddy moisture content (R2 between 0.274 - 0.359 and RMSE between 5.077 - 7.465). The DHT-Factor correction method gave the lowest discrepancy of paddy moisture content during the first 150 minutes of the drying with R2 of 0.987 and RMSE of 0.515. This method also showed low discrepancy results over the entire drying period which indicated that it has high potential for evaluating the real-time paddy moisture content during drying process.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Sirikanchanarak D, Tungtrakul T, Sriboonchitta S. The future of global rice consumption: evidence from dynamic panel data approach. In: Kreinovich V, Sriboonchitta S, Chakpitak N, editors. Predictive Econometrics and Big Data. TES2018; 2018 Jan 10-12; Chiang Mai, Thailand. Cham: Springer; 2018. p. 629-42.

Kongsri S, Sricharoen P, Limchoowong N, Kukusamude C. Tracing the geographical origin of thai hom mali rice in three contiguous provinces of thailand using stable isotopic and elemental markers combined with multivariate analysis. Foods. 2021;10(10):2349.

Vanavichit A, Kamolsukyeunyong W, Siangliw M, Siangliw JL, Traprab S, Ruengphayak S, et al. Thai Hom Mali Rice: origin and breeding for subsistence rainfed lowland rice system. Rice. 2018;11:1-12.

THAI Public Broadcasting Service (THAI PBS). "Thai Jasmine Rice" wins the world championship 2 years in a row [Internet]. 2021 [cited 2021 Dec 15]. Available from: https://www.thaipbs.or.th/news/content/310709. (In Thai)

Department of Foreign Trade. Statistics on Thai jasmine rice exports (by country / yearly comparison) January 2024 [Internet]. 2024 [cited 2024 Oct 22]. Available from: https://www.dft.go.th/th-th/DFT-Service/Service-Data-Information/Statistic-Import-Export/Detail-dft-service-data-statistic/ArticleId/27903/-2567-1-2-3-4-5-6-7-8-9-10-11-12-13-14-15-16-17-18-19-20-21-22-23-24. (In Thai)

Hemhirun S, Bunyawanichakul P. The use of temperature and relative humidity sensors to estimate the final moisture content of the drying process. Int J Eng Res Technol. 2020;9(5):926-32.

Ramli NAM, Rahiman MHF, Rahim RA, Kamarudin LM, Mohamed L, Zakaria A, et al. Measurement of rice moisture content based on quantitative analysis from radio tomography images. Jurnal Teknologi. 2024;86(3):63-78.

Nirmaan AMC, Rohitha Prasantha BD, Peiris BL. Comparison of microwave drying and oven-drying techniques for moisture determination of three paddy (Oryza sativa L.) varieties. Chem Biol Technol Agric. 2020;7:1-7.

Armstrong PR, McNeil S, Manu N, Bosomtwe A, Danso JK, Osekre E, et al. Development and evaluation of a low-cost probe-type instrument to measure the equilibrium moisture content of grain. Appl Eng Agric. 2017;33(5):619-27.

Pathaveerat S, Pruengam P. Low cost measurement of moisture content in long grain paddy. J Stored Prod Res. 2020;89:101728.

Lin L, He Y, Xiao Z, Zhao K, Dong T, Nie P. Rapid-detection sensor for rice grain moisture based on NIR spectroscopy. Appl Sci. 2019;9(8):1654.

Makky M, Santosa, Putri RE, Nakano K. Determination of moisture content in rice using non-destructive short-wave near infrared spectroscopy. AIP Conf Proc. 2019;2155(1):020014.

Helrich K. Official methods of analysis of the Association of Official Analytical Chemists. Rockville: Association of official analytical chemists; 1990.

Pakdeekaew A, Treeamnuk K, Treeamnuk T. Application of PID controller for controlling paddy temperature in hot air pneumatic drying process. The 10th International Conference on Control, Automation and Robotics (ICCAR); 2024 Apr 27-29; Orchard District, Singapore. USA: IEEE; 2024. p. 277-82.

Treeamnuk T, Pengprakhon T, Treeamnuk K. Effect of temperature on moisture sorption isotherm characteristics of Thai jasmine paddy (Khao Dawk Mali 105). LWT. 2024;210:116871.

American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). 2017 ASHRAE Handbook—Fundamentals. Atlanta: ASHRAE; 2017.

Pakdeekaew A, Treeamnuk K, Treeamnuk T, Wongbubpa N. Application of pulse width modulation technique in air humidity control system. Agr Nat Resour. 2023;57(2);321-30.

Boutahri Y, Tilioua A. Machine learning-based predictive model for thermal comfort and energy optimization in smart buildings. Results Eng. 2024;22:102148.

Zolfaghari F, Shojaei S, Khosravi H, Bandak I. Evaluation of the effect of the mixture of soil textural compounds on the strength of the soil crust: coding and optimization. Results Eng. 2024;22:101988.

Du Y, Yan J, Wei H, Xie H, Wu Y, Zhou J. Drying kinetics of paddy drying with graphene far-infrared drying equipment at different IR temperatures, radiations-distances, grain-flow, and dehumidifying-velocities. Case Stud Therm Eng. 2023;43: 102780.

Beigi M, Torki M, Khoshnam F, Tohidi M. Thermodynamic and environmental analyses for paddy drying in a semi-industrial dryer. J Therm Anal Calorim. 2021;146:393-401.