Properties evaluation of natural bitumen-filler mastic mixture

Main Article Content

Abstract

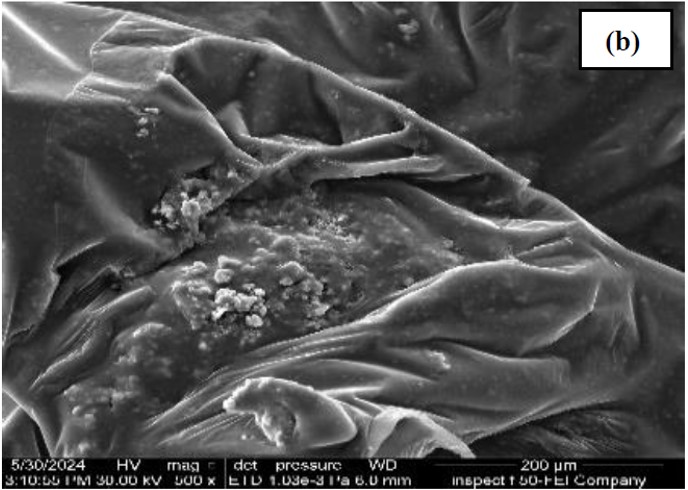

Natural bitumen (NB) is a highly precious material and has drawn increasing attention due to its unique properties, especially since it is available in large quantities and has been used in limited fields. In this research, the exploitation of NB from sulfur springs as an alternative energy resource in the production of asphalt pavement is evaluated. It can be concluded from the experimental results that the chemical composition and surface morphology of NB samples are different from those of base asphalt. Besides, the rheological properties of virgin NB are not sufficient for paving work. To overcome this obstacle, NB from five different springs is modified with limestone filler (LSF) to enhance its properties. LSF is a natural material and is available locally at a low price, usually used as filler material in control asphalt mixtures. The study outcomes reveal that LSF is an effective material and plays a fundamental role in improving the properties of NB since it enhances the resistance against temperature susceptibility and improves the ability of NB to disperse in asphalt mixture. Furthermore, treated NB with LSF boosts the mechanical characteristics, increases the stiffness, and strengthens the resistance against water damage for NB mixtures. Particularly, this research clarified that high Marshall stability is achieved with a treated Al-Mamora sulfur spring-NB mixture, which is 30.4% higher than that of the control mixture. At the same time, the treated Al-Askaree sulfur spring-NB mixture has a stiffness index and tensile strength ratio more than the control mixture by 45% and 3.36%, respectively. In conclusion, adding LSF to NB that is extracted from sulfur springs can produce a new type of asphalt binder more suitable for use in road pavement.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Zhang Y, Sun L, Cheng H. Effects of nominal maximum aggregate size and compaction effort on the mechanical properties of hot-mix asphalt (HMA). Constr Build Mater. 2022;324:126715.

Zhang Y, Cheng H, Sun L, Liu L, Hu Y. Determination of volumetric criteria for designing hard asphalt mixture. Constr Build Mater. 2021;278:122243.

Al-Azawee ET, Latief RH. The feasibility of using styrene-butadiene-styrene (SBS) as modifier in Iraqi bituminous binder. J Eng Sci Technol. 2020;15(3):1596-607.

Latief RH. Evaluation of the performance of glasphalt concrete mixtures for binder course. Int J Adv Sci Eng Inf Technology. 2019;9(4):1251-9.

Rondón-Quintana HA, Ruge-Cárdenas JC, Zafra-Mejía CA. Natural asphalts in pavements: review. Sustainability. 2023;15(3): 2098.

Wang Y, Wang W, Wang L. Understanding the relationships between rheology and chemistry of asphalt binders: a review. Constr Build Mater. 2022;329:127161.

Muttar AA, Zedan TA, Mahmood BA. Analytical comparison study for asphalt and water of Heet sulphurous springs. Journal of University of Anbar for Pure Science. 2009;3(1):45-56. (In Arabic)

Shlimon AG, Mansurbeg H, Othman RS, Gittel A, Aitken CM, Head IM, et al. Microbial community composition in crude oils and asphalts from the Kurdistan region of Iraq. Geomicrobiol J. 2020;37(7):635-52.

Khusnutdinov I, Goncharova I, Safiulina A. Extractive deasphalting as a method of obtaining asphalt binders and low-viscosity deasphalted hydrocarbon feedstock from natural bitumen. Egypt J Pet. 2021;30(2):69-73.

Fakhry MA, Saleh MA, Nayyef AG. Evaluation of the suitability of sulfur springs water for vital uses by studying the physical and chemical properties of some sulfur springs water in the city of Hit. IOP Conf Ser: Earth Environ Sci. 2023;1222:012041.

Alkhafaji MW, Connan J, Engel MH, AL-Jubouri SW. Origin, biodegradation, and water washing of bitumen from the Mishraq Sulfur Mine, northern Iraq. Mar Pet Geol. 2021;124:104786.

Farhan MM, Rabeea MA, Muslim RF, Zidan TA. Chemical composition (saturate fraction) of western Iraq natural bitumen. Mater Today: Proc. 2021;42:2527-33.

Nejres AM, Mustafa YF, Aldewachi HS. Evaluation of natural asphalt properties treated with egg shell waste and low density polyethylene. Int J Pavement Eng. 2022;23(1):39-45.

Nciri N, Cho N. Laboratory methods for identification of geologic origins of natural asphalts. Mater Today: Proc. 2018;5(11):25730-9.

Mohammed FA, Latief RH, Albayati AH. Assessment of traditional asphalt mixture performance using natural asphalt from sulfur springs. J Eng. 2024;30(1):54-73.

Abdul-Jaleel T, Nejres M. Oxidation influence on the chemical content and some rheological properties for natural asphalt to Abu Al jeer, Al Anbar. Iraqi Journal of Desert Studies. 2012;4(1):1-15.

Ahmed F, Latief RH, Albayati A. Effect of natural bitumen on the performance of hot asphalt mixture. GU J Sci. 2024;37(3):1154-70.

Mahmood BA. Influence of waste engine oil addition on the properties of natural asphalt. J Phys: Conf Ser. 2021;1999:012001.

State Corporation for Roads and Bridges. General specification for roads and bridges (SORB/R9)—hot mix asphaltic concrete pavement. Baghdad, Iraq: Department of Planning and Studies, Ministry of Housing and Construction, Republic of Iraq; 2003.

Russo F, Veropalumbo R, Pontoni L, Oreto C, Biancardo SA, Viscione N, et al. Sustainable asphalt mastics made up recycling waste as filler. J Environ Manage. 2022;301:113826.

Tosun HB, Alver A, Baştürk E. Removal of exhaust gas with advanced solar photocatalytic asphalt applications. KSCE J Civ Eng. 2022;26(1):13-24.

Lagos-Varas M, Movilla-Quesada D, Raposeiras AC, Castro-Fresno D, Vega-Zamanillo Á, Cumian-Benavides M. Use of hydrated ladle furnace slag as a filler substitute in asphalt mastics: rheological analysis of filler/bitumen interaction. Constr Build Mater. 2022;332:127370.

Joni HH, Zghair HH. Properties of modified asphalt mixtures with additives of fillers materials. IOP Conf Ser: Mater Sci Eng. 2020;737:012120.

Abdul-Jaleel T, Salem JW, Nejres AM. A new separation, fractionation and improving of Abu- AL jeer asphalt. Anbar J Eng Sc. 2016;7(1):31-41.

Ma L, Varveri A, Jing R, Erkens S. Chemical characterization of bitumen type and ageing state based on FTIR spectroscopy and discriminant analysis integrated with variable selection methods. Road Mater Pavement Des. 2023;24(sup1):506-20.

Yamaguchi K, Sasaki I, Nishizaki I, Meiarashi S, Moriyoshi A. Reinforcing effects of carbon black on asphalt binder for pavement. J Jpn Pet Inst. 2005;48(6):373-9.

Yuan Y, Chen H, Wang Y, Xu S, Xue B, Zou G, et al. How calcium and magnesium ions affect the stability of asphalt with anionic emulsifiers: a molecular dynamics study. Constr Build Mater. 2023;400:132770.

Zhao Z, Wu S, Liu Q, Xie J, Yang C, Wan P, et al. Characteristics of calcareous sand filler and its influence on physical and rheological properties of asphalt mastic. Constr Build Mater. 2021;301:124112.

Tu B, Yang X, Xu S, Liang X, Liu C, Jiang J, et al. Exploring the utilization of PHC pile waste concrete as filler in asphalt mastics. Materials. 2023;16(22):7158.

Woszuk A, Wróbel M, Bandura L, Franus W. Brick debris dust as an ecological filler and its effect on the durability of asphalt mix. Materials. 2020;13(21):5023.

Shukry NAM, Abdul Hassan N, Abdullah ME, Hainin MR, Yusoff NIM, Jaya RP, et al. Effect of various filler types on the properties of porous asphalt mixture. IOP Conf Ser: Mater Sci Eng. 2018;342:012036.

Abd NI, Latief RH. Assessment of rutting resistance for fiber-modified asphalt mixtures. J Eng. 2024;30(5):98-113.

John I, Bangi MR, Lawrence M. Effect of filler and binder contents on air voids in hot-mix asphalt for road pavement construction. Open J Civ Eng. 2021;11:255-89.

Ogundipe OM. Marshall stability and flow of lime-modified asphalt concrete. Transp Res Proc. 2016;14:685-93.

Dimter S, Šimun M, Zagvozda M, Rukavina T. Laboratory evaluation of the properties of asphalt mixture with wood ash filler. Materials. 2021;14(3):575.

Chen Z, Leng Z, Jiao Y, Xu F, Lin J, Wang H, et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J Clean Prod. 2022;344:131124.

Guangxun E, Zhang J, Shen Q, Ji P, Wang J, Xiao Y. Influence of filler type and rheological properties of asphalt mastic on the asphalt mastic–aggregate interaction. Materials. 2023;16(2):574.

Chen Y, Xu S, Tebaldi G, Romeo E. Role of mineral filler in asphalt mixture. Road Mater Pavement Des. 2022;23(2):247-86.

Al-gurah ER, Al-Humeidawi BH. Investigation the effect of different types of mineral fillers on mechanical properties of Hot Mix Asphalt. J Phys: Conf Ser. 2021;1895:012024.

Cheng H, Wang Y, Liu L, Sun L. Effects of using different dynamic moduli on predicted asphalt pavement responses in mechanistic pavement design. Road Mater Pavement Des. 2022;23(8):1860-76.

Cheng H, Wang Y, Liu L, Sun L, Zhang Y, Yang R. Estimating tensile and compressive moduli of asphalt mixture from indirect tensile and four-point bending tests. J Mater Civ Eng. 2021;33(1):04020402.