Enhancing geopolymer mortars: The role of surgical face masks in modifying mechanical and thermal properties

Main Article Content

Abstract

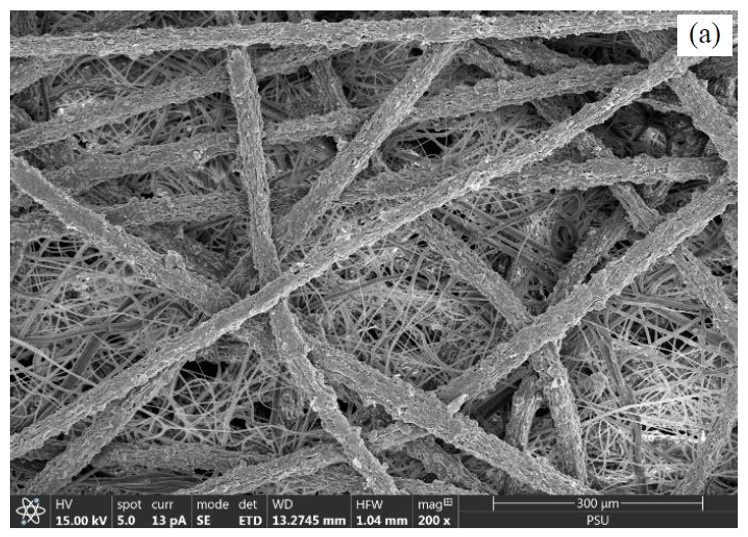

The primary aim of this study is to examine how expanded surgical face masks (SFMs) affect the mechanical properties, thermal conductivity, thermal insulation, and microstructure of geopolymer mortars. In the experimental phase, SFMs were used after removing the inner nose wires and ear loops, then cut into 5 mm × 5 mm pieces. These SFMs were added to various mixtures at different weight percentages (0%, 2%, 4%, and 6%), along with palm oil clinker (POC) and alkali activator. The mechanical properties of the mixtures, such as compressive strength, bulk density, and water absorption, underwent evaluation through testing. Moreover, thermal conductivity and thermal insulation measurements were carried out to gauge the effect of SFMs on this property. Microstructural analysis of the mixtures was conducted using scanning electron microscopy SEM to examine the impact of SFMs on mortar microstructure. The test results indicated that geopolymer mortar containing 2% SFM achieved a compressive strength of 67.3 ksc at 28 days, with an alkaline to fly ash ratio of 0.8 and POC to fly ash ratio of 3. The geopolymer mortars with POC containing SFMs had a bulk density ranging from 1,233 to 1533 kg/m3 at 28 days. Notably, the use of SFMs resulted in a substantial enhancement in thermal conductivity and thermal insulation. Additionally, a strong correlation was found between thermal conductivity and bulk density, suggesting a potential relationship between these properties.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Transparency Market Research. Concrete Block and Brick Manufacturing market [Internet]. 2024 [cited 2024 Aug 15]. Available from: https://www.transparencymarketresearch.com/concrete-block-brick-manufacturing.html.

Arunkumar K, Muthukannan M, Suresh Kumar A, Chithambar Ganesh A, Kanniga Devi R. Hybrid fibre reinforced eco-friendly geopolymer concrete made with waste wood ash: A mechanical characterization study. Eng Appl Sci Res. 2022;49(2):235-47.

Somna R, Saowapun T, Somna K, Chindaprasirt P. Rice husk ash and fly ash geopolymer hollow block based on NaOH activated. Case Stud Constr Mater. 2022;16:e01092.

Mahdi SN, Babu R DV, Hossiney N, Abdulla MMAB. Strength and durability properties of geopolymer paver blocks made with fly ash and brick kiln rice husk ash. Case Stud Constr Mater. 2022;16:e00800.

Hamcumpai K, Nuaklong P, Chindasiriphan P, Jongvivatsakul P, Tangaramvong S, Di Sarno L, et al. High-strength steel fibre-reinforced geopolymer concrete utilising recycled granite waste and rice husk ash. Constr Build Mater. 2024;433:136693.

Klemeš JJ, Fan YV, Tan RR, Jiang P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew Sustain Energy Rev. 2020;127:109883.

Saberian M, Li J, Kilmartin-Lynch S, Boroujeni M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci Total Environ. 2021;769:145527.

Benson NU, Bassey DE, Palanisami T. COVID pollution: impact of COVID-19 pandemic on global plastic waste footprint. Heliyon. 2021;7(2):e06343.

Dhawan R, Bisht BMS, Kumar R, Kumari S, Dhawan SK. Recycling of plastic waste into tiles with reduced flammability and improved tensile strength. Process Saf Environ Prot. 2019;124:299-307.

Lei B, Li W, Tang Z, Tam VWY, Sun Z. Durability of recycled aggregate concrete under coupling mechanical loading and freeze-thaw cycle in salt-solution. Constr Build Mater. 2018;163:840-9.

Iqbal HW, Hamcumpai K, Nuaklong P, Jongvivatsakul P, Likitlersuang S, Pothisiri T, et al. Enhancing fire resistance in geopolymer concrete containing crumb rubber with graphene nanoplatelets. Constr Build Mater. 2024;426:136115.

Haruna S, Jongvivatsakul P, Hamcumpai K, Iqbal HW, Nuaklong P, Likitlersuang S, et al. Multiscale investigation of the impact of recycled plastic aggregate as a fine aggregate replacement on one-part alkali-activated mortar performance. J Build Eng. 2024;86:108768.

Haruna S, Jongvivatsakul P, Kunamisarut A, Iwanami M, Likitlersuang S. Optimizing mechanical properties of one-part alkali-activated mortar with recycled plastic and graphene nanoplatelets using response surface methodology. Constr Build Mater. 2024;450:138701.

Chindasiriphan P, Meenyut B, Orasutthikul S, Jongvivatsakul P, Tangchirapat W. Influences of high-volume coal bottom ash as cement and fine aggregate replacements on strength and heat evolution of eco-friendly high-strength concrete. J Build Eng. 2023;65:105791.

Tabsh SW, Abdelfatah AS. Influence of recycled concrete aggregates on strength properties of concrete. Constr Build Mater. 2009;23(2):1163-7.

Pizoń J, Gołaszewski J, Alwaeli M, Szwan P. Properties of concrete with recycled concrete aggregate containing metallurgical sludge waste. Materials. 2020;13(6):1448.

Kumar G, Mishra SS. Effect of recycled concrete aggregate on mechanical, physical and durability properties of GGBS–fly ash-based geopolymer concrete. Innov Infrastruct Solut. 2022;7:237.

Hassan KE, Brooks JJ, Erdman M. The use of reclaimed asphalt pavement (RAP) aggregates in concrete. Waste Manag Ser. 2000;1:121-8.

Rahman SS, Khattak MJ. Feasibility of reclaimed asphalt pavement geopolymer concrete as a pavement construction material. Int J Pavement Res Technol. 2023;16:888-907.

Linek M, Bacharz M, Piotrowska P. Surface cement concrete with reclaimed asphalt. Materials. 2023;16(7):2791.

Kupaei RH, Alengaram UJ, Jumaat MZB, Nikraz H. Mix design for fly ash based oil palm shell geopolymer lightweight concrete. Constr Build Mater. 2013;43:490-6.

Maghfouri M, Shafigh P, Aslam M. Optimum oil palm shell content as coarse aggregate in concrete based on mechanical and durability properties. Adv Mater Sci Eng. 2018;2018(1):4271497.

Azunna SU. Compressive strength of concrete with palm kernel shell as a partial replacement for coarse aggregate. SN Appl Sci. 2019;1:342.

Hawa A. Strength and microstructural of geopolymer mortar from palm oil ash containing alumina powder with palm oil clinker aggregate. Eng Appl Sci Res. 2022;49(6):731-43.

Hamada HM, Al-Attar AA, Tayeh B, Yahaya FBM. Optimizing the concrete strength of lightweight concrete containing nano palm oil fuel ash and palm oil clinker using response surface method. Case Stud Constr Mater. 2022;16:e01061.

Hawa A, Salaemae P, Abdulmatin A, Ongwuttiwat K, Prachasaree W. Properties of palm oil ash geopolymer containing alumina powder and field Para rubber latex. Civ Eng J. 2023;9(5):1271-88.

Darvish P, Alengaram UJ, Poh YS, Ibrahim S, Yusoff S. Performance evaluation of palm oil clinkersand as replacement for conventional sand in geopolymer mortar. Constr Build Mater. 2020;258:120352.

Salari F, Alengaram UJ, Alnahhal AM, Ibrahim ZB, Yusoff S, Ibrahim MSI, et al. Promulgation of sustainable palm oil clinker sand in the development of structural and non-structural lightweight foamed concrete. Struct Concr. 2023;24(3):3952-68.

Thoudam K, Hossiney, N, Kumar SL, Aex J, Bhalkikar A, Fathima A. Assessing performance of alkali-activated bricks incorporated with processed surgical masks. J Mater Res Technol. 2023;25:6432-45.

Kilmartin-Lynch S, Saberian M, Li J, Roychand R, Zhang G. Preliminary evaluation of the feasibility of using polypropylene fibers from COVID-19 single-use face masks to improve the mechanical properties of concrete. J Clean Prod. 2021;296:126460.

Durmus G, Çelik DN, Demircan RK, Kaplan G. Effect of waste COVID-19 face masks on self-compacting high-strength mortars exposed to elevated temperature. Ain Shams Eng J. 2023;14(8):102058.

Win TT, Jongvivatsakul P, Jirawattanasomkul T, Prasittisopin L, Likitlersuang S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr Build Mater. 2023;391:131845.

ASTM. ASTM C618-22: standard specification for coal fly ash and raw or calcined natural Pozzolan for use in concrete. West Conshohocken: ASTM International; 2022.

Faculty of Medicine Ramathibodi Hospital, Mahidol University. Disinfection of N95 masks and surgical masks with HEAT and UV-C [Internet]. 2020 [cited 2024 Aug 15]. Available from: https://www.rama.mahidol.ac.th/ramacloud/s/yQRm3wl WmKFZKJX. (In Thai)

Xiang Y, Song Q, Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70°C. Am J Infect Control. 2020;48(8):880-2.

ASTM. ASTM C109/C109M-16a: standard test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens). West Conshohocken: ASTM International; 2016.

Bellum RR. Influence of steel and PP fibers on mechanical and microstructural properties of fly ash-GGBFS based geopolymer composites. Ceram Int. 2022;48(5):6808-18.

Amin F, Javed MF, Ahmad I, Asad O, Khan N, Khan AB, et al. Utilization of discarded face masks in combination with recycled concrete aggregate and silica fume for sustainable civil construction projects. Sci Rep. 2024;14:449.

Miah MJ, Pei J, Kim H, Sharma R, Jang JG, Ahn J. Property assessment of an eco-friendly mortar reinforced with recycled mask fiber derived from COVID-19 single-use face masks. J Build Eng. 2023;66:105885.

Saeli M, Senff L, Tobaldi DM, Seabra MP, Labrincha JA. Novel biomass fly ash-based geopolymeric mortars using lime slaker grits as aggregate for applications in construction: influence of granulometry and binder/aggregate ratio. Constr Build Mater. 2019;227:116643.

Ahmmad R, Alengaram UJ, Jumaat MZ, Sulong NHR, Yusuf MO, Rehman MA. Feasibility study on the use of high volume palm oil clinker waste in environmental friendly lightweight concrete. Constr Build Mater. 2017;135:94-103.

Abutaha F, Razak HA, Ibrahim HA. Effect of coating palm oil clinker aggregate on the engineering properties of normal grade concrete. Coatings. 2017;7(10):175.

Lee KP, Yip J, Kan CW, Chiou JC, Yung KF. Reusable face masks as alternative for disposable medical masks: factors that affect their wear-comfort. Int J Environ Res Public Health. 2020;17(18):6623.

Ng SC, Low KS. Thermal conductivity of newspaper sandwiched aerated lightweight concrete panel. Energy Build. 2010;42(12):2452-6.

Sengul O, Azizi S, Karaosmanoglu F, Tasdemir MA. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011;43(2-3):671-6.

Saygili A, Baykal G. A new method for improving the thermal insulation properties of fly ash. Energy Build. 2011;43(11):3236-42.

Khusshefari WH, Demirboğa R, Farhan KZ. Assessment of factors impacting thermal conductivity of cementitious composites—a review. Clean Mater. 2022;5:100127.

Liu MYJ, Alengaram UJ, Juaat MZ, Mo KH. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014;72:238-45.

Akçaözoğlu S, Akçaözoğlu K, Atiş CD. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Comp B Eng. 2013;45(1):721-6.

Albayrak M, Yörükoğlu A, Karahan S, Atlıhan S, Yılmaz Aruntaş H, Girgin I. Influence of zeolite additive on properties of autoclaved aerated concrete. Build Environ. 2007;42(9):3161-5.

Singh RJ, Raut A, Murmu AL, Jameel M. Influence of glass powder incorporated foamed geopolymer blocks on thermal and energy analysis of building envelope. J Build Eng. 2021;43:102520.