A double blade splitting machine for Cyperus sedge culms (Cyperus corymbosus Rottb.)

Main Article Content

Abstract

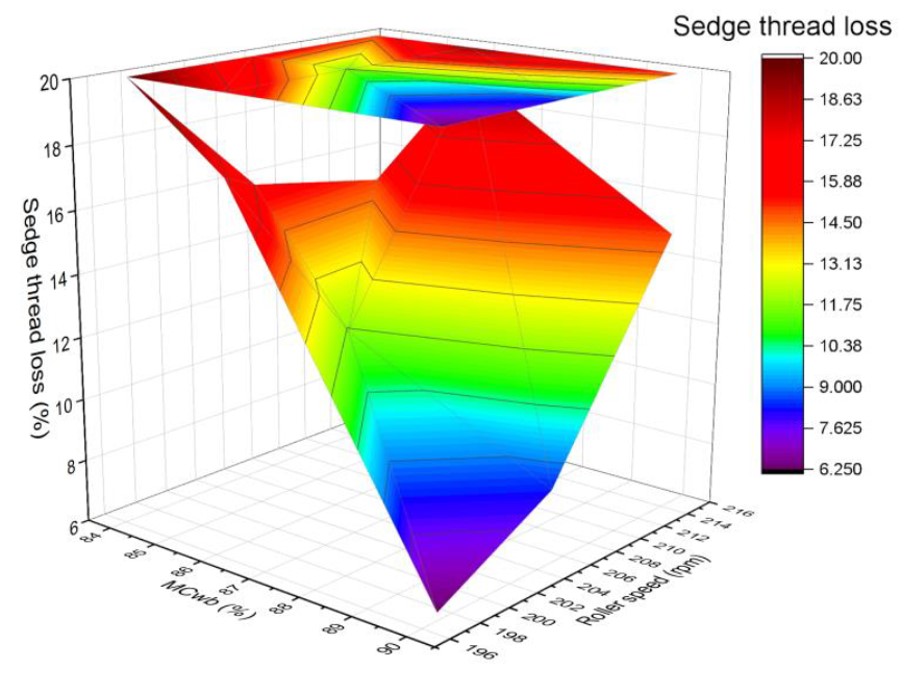

Sedges are a natural material that can be made into mats and other products to replace plastic. Preparing sedge threads includes harvesting, sorting by size and color, splitting, and finally drying them. Splitting is an important step because using equipment can increase process speed. The objective of this research is to design, build, test, and evaluate the performance of a sedge-splitting machine. The main feature of this machine is its two pairs of blades, 7 mm apart, arranged in a perpendicular manner. This allows splitting the sedges into four threads while simultaneously removing the core. Five sedge clums are simultaneously processed. The machine was tested at three roller speeds, 197, 205, and 214 rpm. Its speed is not constant but varies between the lowest and highest speeds. This process was compared to one employing manual labor. The quantity of sedge threads that the machine split varied with its speed. Therefore, the machine’s overall production was estimated by averaging its output at these three speeds. It could process an average of 649.3 sedge culms/h, which is more than three times faster than the manual process, 195.4 culms/h. This research also studied the effect of culm moisture content on the machine’s operating capacity. It was found that moisture content had no effect on the working rate of either the machine or the manual process. However, it did affect the machine’s efficiency. Processing freshly cut culms enabled the highest efficiency, 90%. However, the manual process showed an average 98% efficiency when the culms had a moisture content between 84-90%.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Yagi K. Materials development for sustainable society: ecomaterials. The 39th annual conference of metallurgist of CIM; 2000 Aug 20-23; Ottawa, Canada. p. 3-13.

Halada K, Yamamoto R. The current status of research and development on eco-materials around the world. MRS Bulletin. 2001;26(11):871-8.

Benazir JAF, Manimekalai V, Ravichandran P, Suganthi R, Dinesh DC. Properties of fibres/culm strands from mat sedge - Cyperus pangorei Rottb. BioRes. 2010;5(2):951-67.

Somboon L. The inherit of local wisdom of Chanthabun reed mat and community lifestyle: a case study of Thachabaeb Village in Bang Kacha Sub-district of Chanthaburi Province through knowledge management. Journal of Roi Kaensarn Academi. 2024:9(10):32-44. (In Thai)

Nithisiriwaritkun W, Phonphuak S, Srisaphonphusitti T. Application of creative economy to reed mats products of Nongkoh Village, Ta Triang Tia District, Amphoe Landuan, Surin Province. Rajapark Journal. 2019;13(30):122-32. (In Thai)

Kiddee U. Local wisdom knowledge management on reed mat of Banpang community, Mahasarakham Province [independent study report]. Khon Kaen: College of Local Administration, Khon Kaen University; 2011. (In Thai)

Phason C, Chinsuwan W. Ban Phaeng reed industrial development Tambon Phaeng, Kosumphisai District, Mahasarakham Province. The National and International Conference on Business Management and Innovation; 2015 Sep 19-20; College of Graduate Study in Management, Khon Kaen University (MBA KKU), Thailand. p. 484-90. (In Thai)

MGR Online. 72-year-old grandma fights her life, planted papyrus, sells them to a mat processing factory for a living [Internet]. 2014 [cited 2024 Apr 9]. Available from: https://mgronline.com/local/detail/9570000048410. (In Thai)

Kidane B, Mekonnen Z, Getahun A, Anjulo A, Kassa H, Teshome U, et al. Highland bamboo value chains development to enhance local livelihoods in Southern Ethiopia. J Innov Entrep. 2024;13:50.

Phoungmanee T, Charoensuk K, Jaingamdee P. Development of community product design based on participation of reed woven mat community enterprise group of Ban Huay Tard, Na Dok Kham Sub-district, Na Duang district, Loei province. DEC Journal. 2023;2(2):12-45. (In Thai)

Kuljerm K, Nilklom C, Khanthong B, Thangen W, Moonhom W. Reed weave pilot [bachelor thesis]. Phetchabun: Production Technology Program, Phetchabun Rajabhat University; 2006. (In Thai)

Thonthan C. Automatic system reed split machine. Yasothon: Yasothon Technical College, Office of Vocational Education Commission, Thailand; 2010. (In Thai)

Haines RW, Lye KA. The sedges and rushes of East Africa. Nairobi: East African Natural History Society; 1983.

Taman L. Using rushes and sedges in revegetation of wetland areas in the Southwest of Australia. Western Australia: Water and River commissions; 2001.

Barua IC, Sarmah R, Barua KN. "Koth"- The Assam artisan mat from mash-weeds: an ethnobotanical approach. Research Inspiration. 2016;1(3):437-48.

Pongrat A, Wanikorn N, Boonchareon P. Comparison of Thai sedge varieties in the low land part of Northeastern Thailand. Thailand: The National Research Council of Thailand; 2001. Report no. 04105861-0005.

Jana K, Das SK, Puste AM. Production economics of mat-sedges (Cyperus Tegetum Roxb.) cultivation as influenced by water management practices for economic stability of resource-poor rural people of West Bengal, India. Int J Environ Agric Res. 2015;1(2):27-32.

Srila M. Longitudinal cutting equipment for Papyrus reed. Prawarun Agricultural Journal. 2015;12(2):123-8. (In Thai)

Zhu H, Wang D, He X, Shang S, Zhao Z, Wang H, et al. Study on plant crushing and soil throwing performance of bionic rotary blades in Cyperus esculentus harvesting. Machines 2022;10(7):562.

Baye B, Tesfaye T, Teshome Z. Optimization of extraction techniques for processing and utilization of a new fiber from Cyperus Dichrostachus A. Rich plant. Polym Bull. 2024;81:2869-88.

Xia X, Jin Y, Zhao H, Wang G, Huang D. Optimization and experiment of hot air drying process of Cyperus esculentus Seeds. Agriculture. 2023;13(3):617.

Jaito K, Treeamnuk T, Treeamnuk K. Water hyacinth slitting and cutting machine. The 14th TSAE National Conference and the 6th TSAE International Conference 2013; 2013 Apr 1-4; Prachuap Khiri Khan, Thailand. p. 266-70. (In Thai)

Inthata S, Srihabutra P, Thuanmunla J, Supad T, Inpalad P. Development of two-way putty banana slicer auto-machine. Journal of Science and Technology, Rajabhat Maha Sarakham University. 2022;5(2):103-115. (In Thai)

Siriporn-akkharachai S, Siriporn-akkharachai T. Longitudinal and horizontal-aligned banana slicing machine. RMUTP Sci J. 2016;10(2):30-42. (In Thai)

Huang Y, Ji Y, Yu W. Development of bamboo scrimber: a literature review. J Wood Sci. 2019;65:25.

Ohuchi T, Nakahara M, Murase Y. Cross-sectional cutting of bamboo with a pair of shearing blades for bamboo cube production. J Wood Sci. 2006;52:274-8.

Guwo AN. Development of a ginger splitting machine [thesis]. Nigeria: Ahmadu Bello University; 2008.

Agbetoye LAS, Balogun A. Design and performance of a multi-crop slicing machine. Proceedings of the 5th CIGR Section VI International Symposium on Food Processing, Monitoring Technology in Bioprocess and Food Quality management; 2009 Aug 31 - Sep 2; Potsdam, Germany. p. 622-40.

Yangyuen S, Laohavanich J. Development of a semi-automatic macadamia cracking machine. Eng Appl Sci Res. 2018;45(4): 256-61.