A Taguchi fractional factorial design approach to assessing Cattle-Poultry-Hog manure mix ratio influences on biogas yield

Main Article Content

Abstract

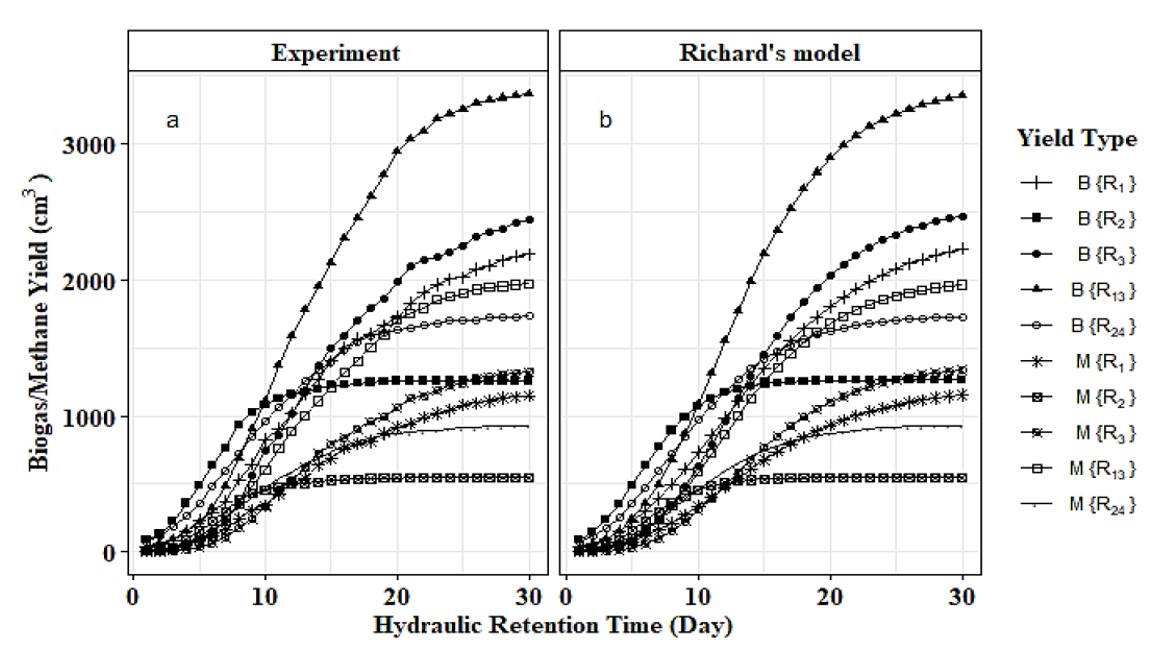

Methane production from co-substrate (CS) bio-digestion of cow, poultry and hog manure (CM: PM: HM) can be a potential energy alternative supply. The effect of the co-digestion of these CSs on biogas and methane yield was investigated in this study. Using the Taguchi fractional factorial design (TFFD) method, twenty-eight experiments with varying CSs mix ratios (CMR) were prepared including three experiments made up of the three individual substrates (ISs). Under mesophilic temperature conditions, controlled volatile solid concentration, and a thirty-day hydraulic retention time with all other physicochemical conditions kept unconstrained, the daily cumulative biogas and methane yields were collected and evaluated. Using these, the ultimate methane yields ( were predicted using Richard's kinetic model. The relative of the CSs with those of the ISs was compared to establish the synergistic properties of the CSs. The effects of the CSs interactions were also assessed using a quartic polynomial regression model. Furthermore, the optimal CMR necessary for producing the maximum methane yield was also predicted using the TFFD analysis. The range for the CMRs and ISs was (0.93-1.97) and (0.55-1.31) litres respectively indicating that higher methane yield production is possible with the use of CSs. However, to achieve this, the CMRs have to be carefully chosen. The relative was also found to be higher for all the CMRs further indicating the superiority of co-digesting the substrate rather than mono-digestion. The CSs interactions model showed that the addition of HM and PM produced the best and worst synergistic effects respectively. The TFFD analysis revealed an optimal CMR for CM: PM: HM to be 5:1:5.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Statista. African countries with the largest population as of 2021 [Internet]. 2021 [cited 2021 Apr 12]. Available from: https://www.statista.com/statistics/1121246/population-in-africa-by-country/.

IEA. Africa energy outlook 2019 [Internet]. 2019 [cited 2021 Apr 12]. Available from: https://www.iea.org/reports/africa-energy-outlook-2019.

Esan OC, Anthony EJ, Obaseki SO. Utilization of renewable energy for improved power generation in Nigeria. J Phys Conf Ser. 2019;1299:012026.

Bazilian M, Onyeji I, Aqrawi PK, Sovacool BK, Ofori E, Kammen D, et al. Oil, energy poverty and resource dependence in West Africa. J Energy Nat Resour Law. 2013;31(1):33-53.

Adewuyi OB, Kiptoo MK, Afolayan AF, Amara T, Alawode OI, Senjyu T. Challenges and prospects of Nigeria’s sustainable energy transition with lessons from other countries’ experiences. Energy Rep. 2020;6:993-1009.

Somoye OA. Energy crisis and renewable energy potentials in Nigeria: a review. Renew Sustain Energy Rev. 2023;188:113794.

IEA. Nigeria energy outlook [Internet]. Nigeria: International Energy Agency; 2019 [cited 2020 Nov 7]. Available from: https://www.iea.org/articles/nigeria-energy-outlook.

Uzoma CC, Amadi KC. Energy access: a key to rural development in Nigeria. Res Rev: J Soc Sci. 2019;5(1):452-6.

Izekor D, Amiandamhen S. Utilization of fuelwood as household energy among residents of benin metropolis, Nigeria. Nigerian J Agric Food Environ. 2017;13(2):174-8.

Gioda A, Tonietto GB, de Leon AP. Exposure to the use of firewood for cooking in Brazil and its relation with the health problems of the population. Cien Saude Colet. 2019;24(8):3079-88.

Owusu PA, Asumadu-Sarkodie S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016;3(1):1167990.

Kabeyi MJB, Olanrewaju OA. Biogas production and applications in the sustainable energy transition. J Energy. 2022;2022:8750221.

Asquer C, Pistis A, Scano EA. Characterization of fruit and vegetable wastes as a single substrate for the anaerobic digestion. Environ Eng Manag J. 2013;12(S11):89-92.

Wei L, Qin K, Ding J, Xue M, Yang C, Jiang J, et al. Optimization of the co-digestion of sewage sludge, maize straw and cow manure: microbial responses and effect of fractional organic characteristics. Sci Rep. 2019;9(1):2374.

Atelge MR, Krisa D, Kumar G, Eskicioglu C, Nguyen DD, Chang SW, et al. Biogas production from organic waste: recent progress and perspectives. Waste Biomass Valor. 2020;11:1019-40.

Aworanti OA, Agarry SE, Ogunleye OO. Biomethanization of cattle manure, pig manure and poultry manure mixture in co-digestion with waste of pineapple fruit and content of chicken-gizzard- part i: kinetic and thermodynamic modelling studies. Open Biotechnol J. 2017;11:36-53.

Adebimpe OA, Edem IE, Ayodele OL. Investigation of the effects of starting ph, mass and retention time on biogas production using poultry droppings as feedstock. Niger J Technol. 2020;39(1):203-11.

Goswami R, Chattopadhyay P, Shome A, Banerjee SN, Chakraborty AK, Mathew AK, et al. An overview of physico-chemical mechanisms of biogas production by microbial communities: a step towards sustainable waste management. 3 Biotech. 2016;6(1):72.

Adeoti O, Ilori MO, Oyebisi TO, Adekoya LO. Engineering design and economic evaluation of a family-sized biogas project in Nigeria. Technovation. 2000;20(2):103-8.

Roubík H, Mazancová J, Le Dinh P, Dinh Van D, Banout J. Biogas quality across small-scale biogas plants: a case of central vietnam. Energies. 2018;11(7):1794.

Olafadehan O, Adewumi K. Livestock management and production system of agropastoralists in the derived savanna of South-West Nigeria. Trop Subtrop Agroecosystems. 2010;12(3):685-91.

ODI. Highlights of the Nigeria livestock resources report [Internet]. 1993 [cited 2020 Nov 7]. Available from: https://www.odi.org/publications/4464-livestock-cattle-goats-cashmere-cameroon-china-nigeria-fulani.

Emmanuel OE, Igwilo KC, Samuel SE, Kale O. A review on waste to biogas sources and its potential in Nigeria. Int J Eng Technol. 2018;7(4):5960-6.

Jekayinfa SO, Linke B, Pecenka R. Biogas production from selected crop residues in Nigeria and estimation of its electricity value. Int J Renew Energy Technol. 2015;6(2):101-18.

Marchioro V, Steinmetz RLR, do Amaral AC, Gaspareto TC, Treichel H, Kunz A. Poultry litter solid state anaerobic digestion: effect of digestate recirculation intervals and substrate/inoculum ratios on process efficiency. Front Sustain Food Syst. 2018;2:46.

Adebayo AO, Jekayinfa SO, Linke B. Effect of co-digesting pig slurry with maize stalk on biogas production at mesophilic temperature. J Multidiscip Eng Sci Technol. 2015;2(8):2295-300.

Kemausuor F, Adaramola MS, Morken J. A review of commercial biogas systems and lessons for Africa. Energies. 2018;11(11):2984.

Mshandete AM, Parawira W. Biogas technology research in selected sub-Saharan African countries - a review. Afr J Biotechnol. 2009;8(2):116-25.

FAO. Africa sustainable livestock 2050: Nigeria - What do the long term projections say? [Internet]. USA: Food and Agriculture Organization of the United Nations; 2018 [cited 2020 Dec 12]. Available from: http://www.fao.org/3/CA3374EN/ca3374en.pdf.

FAO. Africa sustainable livestock 2050: livestock and livelihoods spotlight Nigeria. Cattle and poultry sectors [Internet]. USA: Food and Agriculture Organization of the United Nations; 2018 [cited 2020 Dec 12]. Available from: http://www.fao.org/3/CA2149EN/ca2149en.pdf.

Achinas S, Euverink GJW. Elevated biogas production from the anaerobic co-digestion of farmhouse waste: insight into the process performance and kinetics. Waste Manag Res. 2019;37(12):1240-9.

Rabii A, Aldin S, Dahman Y, Elbeshbishy E. A review on anaerobic co-digestion with a focus on the microbial populations and the effect of multi-stage digester configuration. Energies. 2019;12(6):1106.

Nnabuchi MN, Akubuko FO, Augustine C, Ugwu GZ. Assessment of the effect of co-digestion of chicken dropping and cow dung on biogas generation. Int Res J Eng Sci Technol Innov. 2012;1(9):238-43.

Ingabire H, M’arimi MM, Kiriamiti KH, Ntambara B. Optimization of biogas production from anaerobic co-digestion of fish waste and water hyacinth. Biotechnol Biofuels Bioprod. 2023;16(1):110.

Das A, Mondal C. Biogas production from co-digestion of substrates: a review. Int Res J Environ Sci. 2016;5(1):49-57.

Tumusiime E, Kirabira JB, Musinguzi WB. Optimization of substrate mixing ratios for wet anaerobic digestion of selected organic waste streams for productive biogas systems. Energy Rep. 2022;8:10409-17.

Chaher NEH, Engler N, Nassour A, Nelles M. Effects of co-substrates’ mixing ratios and loading rate variations on food and agricultural wastes’ anaerobic co-digestion performance. Biomass Conv Bioref. 2023;13(8):7051-66.

Magbanua BS, Adams TT, Johnston P. Anaerobic codigestion of hog and poultry waste. Bioresour Technol. 2001;76(2):165-8.

Mahato P, Adhikary S, Goyette B, Rajagopal R. Two-stage (liquid-solid) anaerobic mono-digestion of ammonia-rich chicken manure at low-temperature: operational strategy and techno-economic assessment. Resour Conserv Recycl Adv. 2023;19:200168.

Jeung JH, Chung WJ, Chang SW. Evaluation of anaerobic co-digestion to enhance the efficiency of livestock manure anaerobic digestion. Sustainability. 2019;11(24):7170.

Cimbala JM. Experimental design [Internet]. 2014 [cited 2020 Dec 21]. Available from: https://www.me.psu.edu/cimbala/me345/Lectures/Experimental_Design.pdf.

Allen TT. Introduction to engineering statistics and lean sigma. Statistical quality control and design of experiments and systems. 3rd ed. London: Springer; 2019.

LibreTexts. Design of experiments via Taguchi methods - orthogonal arrays [Internet]. 2020 [cited 2020 Dec 21]. Available from: https://eng.libretexts.org/Bookshelves/Industrial_and_Systems_Engineering/Book%3A_Chemical_Process_Dynamics_and_Controls_(Woolf)/14%3A_Design_of_Experiments/14.01%3A_Design_of_Experiments_via_Taguchi_Methods_-_Orthogonal_Arrays#:~:text=Also%2C%20the%20Taguchi%20method%20allows,experiments%20to%20test%20all%20variables.

Fei NC, Mehat NM, Kamaruddin S. Practical applications of Taguchi method for optimization of processing parameters for plastic injection moulding: a retrospective review. ISRN Ind Eng. 2013;2013:462174.

Kurata K, Shimada K, Takamatsu H. Application of the Taguchi method to explore a robust condition of tumor-treating field treatment. PLoS One. 2022;17(1):e0262133.

Sudharsan NM, Ng EY. Parametric optimization for tumour identification: bioheat equation using anova and the Taguchi method. Proc Inst Mech Eng H. 2000;214(5):505-12.

Das D, Abhishek, Sharma P. Application of Taguchi method and response surface methodology (rsm) for parametric optimization of natural convection heat transfer inside a triangular porous enclosure with in-line rectangular finned array. Exp Heat Transf. 2023:1-15.

Liao HT, Shie JR, Yang YK. Applications of Taguchi and design of experiments methods in optimization of chemical mechanical polishing process parameters. Int J Adv Manuf Technol. 2008;38(7):674-82.

Farhangi H, Mozafari V, Roosta HR, Shirani H, Farhangi M. Optimizing growth conditions in vertical farming: enhancing lettuce and basil cultivation through the application of the Taguchi method. Sci Rep. 2023;13(1):6717.

Tabaraki R, Nateghi A. Application of Taguchi l16orthogonal array design to optimize hydrazine biosorption by Sargassum ilicifolium. Environ Prog Sustainable Energy. 2016;35(5):1450-7.

Kanakavalli PB, More SR. Determining optimal parameters using Taguchi’s design of experiments (DOE) for improving the quality of biogas generation process. Eng Res Express. 2022;4(2):025020.

Altinbas M, Cicek OA. Anaerobic co-digestion of chicken and cattle manures: free ammonia inhibition. Energy Sources A: Recovery Util Environ Eff. 2019;41(9):1097-109.

Ogunwande GA, Osunade JA, Adeagbo AO, Fakuyi OF. Effects of co-digesting swine manure with chicken manure on biogas production. Ife J Sci. 2013;15(1):1-8.

Li J, Jha AK, Bajracharya TR. Dry anaerobic co-digestion of cow dung with pig manure for methane production. Appl Biochem Biotechnol. 2014;173(6):1537-52.

Chukwuma EC, Umeghalu ICE, Orakwe LC, Bassey EE, Chukwuma JN. Determination of optimum mixing ratio of cow dung and poultry droppings in biogas production under tropical condition. Afr J Agric Res. 2013;8(18):1940-8.

Kasisira LL, Muyiiya ND. Assessment of the effect of mixing pig and cow dung on biogas yield. Agricl Eng Int: CIGR EJ. 2009;XI:1-7.

Olanrewaju OO, Olubanjo OO. Development of a batch-type biogas digester using a combination of cow dung, swine dung and poultry dropping. Int J Clean Coal Energ. 2019;8(2):15-31.

Samuel O, Michael O, Raphael O, Joseph O. Co-digestion of livestock wastes for biogas production. Bioeng Biosci. 2016;4(3):42-9.

Belaid M, Matheri AN, Mdluli NP, Muzenda E. Biochemical methane potential analysis using cow dung, chicken manure and pig manure under mesophilic conditions. International Conference on Industrial Engineering and Operations Management; 2019 Mar 5-7; Bangkok, Thailand. p. 1710-8.

Mahmoodi P, Farmanbordar S, Karimi K. Analytical methods in biogas production. In: Tabatabaei M, Ghanavati H, editors. Biogas, biofuel and biorefinery technologies, vol 6. Cham: Springer; 2018. p. 221-38.

Liu Z, Lv J. The effect of total solids concentration and temperature on biogas production by anaerobic digestion. Energy Sources A: Recovery Util Environ Eff. 2016;38(23):3534-41.

Houkom RL, Butchbaker AF, Brusewitz GH. Effect of moisture content on thermal diffusivity of beef manure. Trans ASAE. 1974;17(5):0973-7.

Chen YR. Thermal properties of beef cattle manure. Agric Wastes. 1983;6(1):13-29.

Landry H, Lague C, Roberge M. Physical and rheological properties of manure products. Appl Eng Agric. 2004;20(3):277-88.

Lorimor J, Sutton A. Manure characteristics. Manure management systems series. MWPS-18 Section 1. Iowa: Iowa State University; 2004.

Fischer JR, Iannotti EL, Porter JH. Anaerobic digestion of swine manure at various influent solids concentrations. Agric Wastes. 1984;11(3):157-66.

Rennuit C, Sommer SG. Decision support for the construction of farm-scale biogas digesters in developing countries with cold seasons. Energies. 2013;6(10):5314-32.

Hill DT. Steady-state mesophilic design equations for methane production from livestock wastes. Trans ASAE. 1991;34(5):2157-63.

Zwietering MH, Jongenburger I, Rombouts FM, van 't Riet K. Modeling of the bacterial growth curve. Appl Environ Microbiol. 1990;56(6):1875-81.

Tjørve KMC, Tjørve E. The use of gompertz models in growth analyses, and new gompertz-model approach: an addition to the unified-richards family. PLoS One. 2017;12(6):e0178691.

Koch K. Calculating the degree of degradation of the volatile solids in continuously operated bioreactors. Biomass Bioenergy. 2015;74:79-83.

Adelard L, Poulsen TG, Rakotoniaina V. Biogas and methane yield in response to co- and separate digestion of biomass wastes. Waste Manag Res. 2015;33(1):55-62.

Aufmann RN, Nation RD. Algebra and trigonometry. 8th ed. Cengage Learning; 2014.

Hungerford TW, Shaw DJ. Contemporary precalculus: a graphing approach. 5th ed. Cengage Learning; 2008.

Alfarjani FA. Design and optimization of process parameters in bio-gas production systems [thesis]. Dublin: Dublin City University; 2012.

Güngör-Demirci G, Demirer GN. Effect of initial cod concentration, nutrient addition, temperature and microbial acclimation on anaerobic treatability of broiler and cattle manure. Bioresour Technol. 2004;93(2):109-17.

Olojede MA, Ogunkunle O, Ahmed NA. Quality of optimized biogas yields from co-digestion of cattle dung with fresh mass of sunflower leaves, pawpaw and potato peels. Cogent Eng. 2018;5(1):1538491.

Hamilton DW. Anaerobic digestion of animal manures: Methane production potential of waste materials [Internet]. 2016 [cited 2020 Dec 27]. Available from: https://extension.okstate.edu/fact-sheets/anaerobic-digestion-of-animal-manures-methane-production-potential-of-waste-materials.html.

Orhorhoro EK, Ebunilo PO, Sadjere GE. Experimental determination of effect of total solid (ts) and volatile solid (vs) on biogas yield. Am J Mod Energy. 2017;3(6):131-5.

Paolini V, Petracchini F, Segreto M, Tomassetti L, Naja N, Cecinato A. Environmental impact of biogas: a short review of current knowledge. J Environ Sci Health A. 2018;53(10):899-906.

Prabhudessai V, Ganguly A, Mutnuri S. Biochemical methane potential of agro wastes. J Energy. 2013;2013:350731.

Yi J, Dong B, Jin J, Dai X. Effect of increasing total solids contents on anaerobic digestion of food waste under mesophilic conditions: performance and microbial characteristics analysis. PLoS One. 2014;9(7):e102548.

Yin DM, Uwineza C, Sapmaz T, Mahboubi A, De Wever H, Qiao W, et al. Volatile fatty acids (VFA) production and recovery from chicken manure using a high-solid anaerobic membrane bioreactor (AnMBR). Membranes. 2022;12(11):1133.

Haryanto A, Triyono S, Wicaksono NH. Effect of hydraulic retention time on biogas production from cow dung in a semi continuous anaerobic digester. Int J Renew Energy Dev. 2018;7(2):93-100.

Hansen KH, Angelidaki I, Ahring BK. Improving thermophilic anaerobic digestion of swine manure. Water Res. 1999;33(8):1805-10.

Díaz-Vázquez D, Alvarado-Cummings SC, Meza-Rodríguez D, Senés-Guerrero C, de Anda J, Gradilla-Hernández MS. Evaluation of biogas potential from livestock manures and multicriteria site selection for centralized anaerobic digester systems: the case of Jalisco, México. Sustainability. 2020;12(9):3527.

Tufaner F, Avsar Y. Effects of co-substrate on biogas production from cattle manure: a review. Int J Environ Sci Technol. 2016;13:2303-12.

Ahuja V, Sharma C, Paul D, Dasgupta D, Saratale GD, Banu JR, et al. Unlocking the power of synergy: cosubstrate and coculture fermentation for enhanced biomethane production. Biomass Bioenergy. 2024;180:106996.

Córdoba V, Fernández M, Santalla E. The effect of substrate/inoculum ratio on the kinetics of methane production in swine wastewater anaerobic digestion. Environ Sci Pollut Res. 2018;25(22):21308-17.

Zhao T, Chen Y, Yu Q, Shi D, Chai H, Li L, et al. Enhancement of performance and stability of anaerobic co-digestion of waste activated sludge and kitchen waste by using bentonite. PLoS One. 2019;14(7):e0218856.

Jurgutis L, Slepetiene A, Volungevicius J, Amaleviciute-Volunge K. Biogas production from chicken manure at different organic loading rates in a mesophilic full scale anaerobic digestion plant. Biomass Bioenergy. 2020;141:105693.

Tawfik A, Eraky M, Osman AI, Ai P, Zhou Z, Meng F, et al. Bioenergy production from chicken manure: a review. Environ Chem Lett. 2023;21(5):2707-27.

Gaworski M, Jabłoński S, Pawlaczyk-Graja I, Ziewiecki R, Rutkowski P, Wieczyńska A, et al. Enhancing biogas plant production using pig manure and corn silage by adding wheat straw processed with liquid hot water and steam explosion. Biotechnol Biofuels. 2017;10(1):259.

Antony J, Kaye M. The Taguchi approach to industrial experimentation. In: Antony J, Kaye M, editors. Experimental quality. Boston: Springer; 2000. p. 47-72.

Mimitab. How Taguchi designs differ from factorial designs [Internet]. 2017 [cited 2024 Mar 9]. Available from: https://blog.minitab.com/en/applying-statistics-in-quality-projects/how-taguchi-designs-differ-from-factorial-designs.

Lewis CD. Industrial and business forecasting methods: a practical guide to exponential smoothing and curve fitting. London: Butterworth Scientific; 1982.

Gaby JC, Zamanzadeh M, Horn SJ. The effect of temperature and retention time on methane production and microbial community composition in staged anaerobic digesters fed with food waste. Biotechnol Biofuels. 2017;10(1):302.

Filer J, Ding HH, Chang S. Biochemical methane potential (BMP) assay method for anaerobic digestion research. Water. 2019;11(5):921.

El Asri O, Afilal ME, Laiche H, Elfarh L. Evaluation of physicochemical, microbiological, and energetic characteristics of four agricultural wastes for use in the production of green energy in moroccan farms. Chem Biol Technol Agric. 2020;7(1):21.