Influence of prickly pear gum on the physical and mechanical properties of adobe reinforced with palm fiber

Main Article Content

Abstract

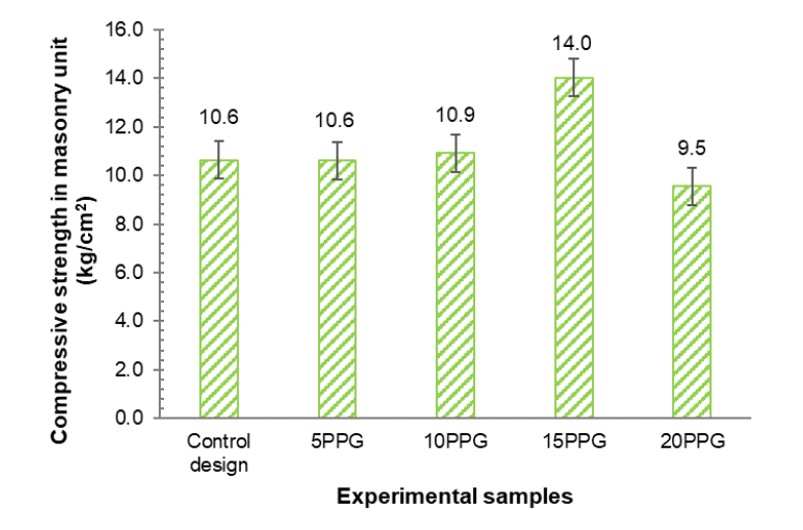

Throughout history, adobe has been essential to many cultures, but its vulnerability to climate and load-bearing limitations have led to research into new natural materials to improve it. Therefore, the objective of this research was to evaluate the influence of prickly pear gum on the physical and mechanical properties of adobe reinforced with palm fiber. Peruvian standard E.080 was used for adobe preparation under an experimental design, preparing samples with 5, 10, 15 and 20% of prickly pear gum (PPG) to replace the volume of water, reinforcing it with 0.25, 0.5, 1 and 1.5% of palm fiber (PF) by weight of the soil, carrying out tests to determine the physical and mechanical properties of the adobe under study. The results revealed that the optimal dosage was 15% PPG + 0.5% PF, suction and warping decreased by 27% and 3.4% respectively, and absorption increased by 68% compared to the control design. Compression strength in masonry unit, flexural strength in masonry unit, compressive strength in prisms, and diagonal shear strength walls showed significant increases of 24.47, 98, 24.39, and 73.4%, respectively, compared to the control design. It was concluded that the use of PPG and PF provides significant benefits to the physical and mechanical properties of adobe.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Himouri K, Hamouine A, Guettatfi L. Compressive creep and ultrasonic characterization of adobe bricks stabilized with quicklime, portland cement, and date palm fibers. Int J Archit Herit. 2023:1-20.

Guettatfi L, Hamouine A, Himouri K, Labbaci B. Mechanical and water durability properties of adobes stabilized with white cement, quicklime and date palm fiber. Int J Archit Herit. 2023;17(4):677-91.

Bougtaib K, Jamil Y, Nasla S, Gueraoui K, Cherraj M. Compressed earth blocks reinforced with fibers (Doum Palm) and stabilized with lime: manual compaction procedure and influence of addition on mechanical properties and durability. JP J Heat Mass Transf. 2022;26:157-77.

UNE. UNE 41410:2008 - Compressed earth blocs for walls and partitions. Definitions, specifications and test methods. Madrid: AENOR; 2008. (In Spanish)

Meybodian H, Eslami A, Morshed R. Sustainable lateral strengthening of traditional adobe walls using natural reinforcements. Constr Build Mater. 2020;260:119892

Alhakim G, Jaber L, Baalbaki O, Barraj F. Utilization of Fan Palm, Date Palm, and Phragmites Australis fibers for improving the mechanical behavior of sandy soil. Geomech Energy Environ. 2023;33:100427.

Ige O, Danso H. Physical-mechanical and thermogravimetric analysis of adobe masonry units reinforced with banana pseudo-stem fibers for sustainable construction. Constr Build Mater. 2021;273:121686.

Dominguez-Santos D, Moya Bravo JA. Structural and mechanical performance of adobe with the addition of high-density polyethylene fibres for the construction of low-rise buildings. Eng Fail Anal. 2022;139:106461.

Zhang L, Zhou T, Zhang Z, Tan W, Liang Z. Near-surface-mounted retrofitting of adobe walls using different materials: evaluation of seismic performance. Structures. 2023;54:1149-63.

Mellaikhafi A, Tilioua A, Benallel A. Thermal performance assessment of a wall built with earth-based adobes and reinforced with pinnate leaves fibers. Mater Today Proc. 2022;58(4):1535-40.

Lkouen A, Lamrani M, Khabbazi A. Numerical study of thermal stress of a building material based on clay and date palm fibers. Mater Today Proc. In press 2023.

El bourka A, Koutous A, Hilali E. A review on the use of date palm fibers to reinforce earth-based construction materials. Mater Today Proc. In press 2023.

Eslami A, Mohammadi H, Mirabi Banadaki H. Palm fiber as a natural reinforcement for improving the properties of traditional adobe bricks. Constr Build Mater. 2022;325:126808.

Mellaikhafi A, Ouakarrouch M, Benallel A, Tilioua A, Ettakni M, Babaoui A, et al. Characterization and thermal performance assessment of earthen adobes and walls additive with different date palm fibers. Case Stud Constr Mater. 2021;15:e00693.

Khoudja D, Taallah B, Izemmouren O, Aggoun S, Herihiri O, Guettala A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr Build Mater. 2021;270:121824.

Guettatfi L, Hamouine A, Himouri K. Hydric behavior of adobes stabilized with quicklime, cement and date palm fibers. MRS Adv. 2022;7(8):619-24.

AlShuhail K, Aldawoud A, Syarif J, Abu Abdoun I. Enhancing the performance of compressed soil bricks with natural additives: wood chips and date palm fibers. Constr Build Mater. 2021;295:123611.

Mohammadi H, Eslami A, Morshed R. Experimental evaluation into improving the mechanical properties of adobe using palm fibers. Amirkabir J Civ Eng. 2022;54(6):465-8.

Abdeldjebar R, Hamouine A, Fouchal F, Labbaci B, Zebair A. Effects of treated date palm fiber on durability of stabilized earth blocks (seb). Int J Civ Eng Technol. 2018;9(5):293-305.

Zaidi A, Izemmouren O, Bachir T, Guettala A. Mechanical and durability properties of adobe blocks filled with date palm wastes. World J Eng. 2022;19(4):532-45.

Aparicio JG, De León Monter EG, Lara NO, Garcia RE, Rojas-Valencia MN. Study of the properties of the Echerhirhu-Block made with Opuntia ficus mucilage for use in the construction industry. Case Stud Constr Mater. 2019;10:e00216.

Taallah B, Guettala A. The mechanical and physical properties of compressed earth block. Constr Build Mater. 2016;104:52-62.

Babé C, Kidmo DK, Tom A, Ngono Mvondo RR, Kola B, Djongyang N. Effect of neem (Azadirachta Indica) fibers on mechanical, thermal and durability properties of adobe bricks. Energy Rep. 2021;7(S5):686-98.

ASTM. ASTM D2487: Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). West Conshohocken: ASTM International; 2011.

ASTM. ASTM D4318: Standard test methods for liquid limit, plastic limit, and plasticity index of soils. West Conshohocken: ASTM International; 2017.

ASTM. ASTM D2216: Standard test methods for laboratory determination of water (moisture) content of soil and rock by mass. West Conshohocken: ASTM International; 2019.

Burbano-Garcia C, Araya-Letelier G, Astroza R, Silva YF. Adobe mixtures reinforced with fibrillated polypropylene fibers: Physical/mechanical/fracture/durability performance and its limits due to fiber clustering. Constr Build Mater. 2022;343:128102.

ASTE. ASTM C188: Standard test method for density of hydraulic cement. West Conshohocken: ASTM International; 2017.

Minister of Housing, Construction and Sanitation of Peru. Norma E.080 Diseño y Construcción de Tierra Reforzada. ANEXO - Resolución Ministerial N° 121-2017-VIVIENDA. Lima: Minister of Housing, Construction and Sanitation of Peru; 2017. (In Spanish)

Vatani Oskouei A, Afzali M, Madadipour M. Effect of reinforcement the mortar on adobe walls performance. Amirkabir J Civ Eng. 2017;49(2):119-120.

Bolaños Rodríguez J. Resistencia a compresión, flexión y absorción del adobe compactado con adición de goma de tuna [Thesis]. Cajamarca: Universidad Privada del Norte; 2016. (In Spanish)