A Selection of Plant Layouts With Analytical Hierarchy Process: A Case Study on Transformer Manufacturing Process

Main Article Content

Abstract

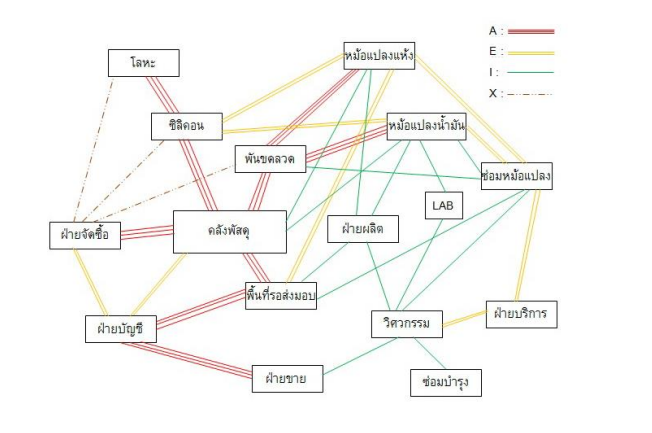

This paper presents an approach to the application of the Analytical Hierarchical Process for the selection of the best plant layout for the transformer manufacturing process. There are five criteria to be used in the decision-making which are convenience and safety, efficient use of space, material handling distance, material flow, and flexibility in use. The research begins with an analysis of the problems of the current plant layout to establish the relationship of each activity occurring within the factory area in order to use the data to design 3 alternative plant layouts by using the principle of Systematic Layout Planning. The Analytical Hierarchical Process is then used to assist in deciding the best plant layout. It is found that plant layout 3 is the most suitable. On comparing the efficiency of the current plant layout with the selected, it is found that the layout improvement reduces the distance of workflow in the case study plant by 52%. In terms of space efficiency, it is found that the space efficiency of the new plant improves by 62.9%, and the average time the workpiece required to be in the production system decreased by 28.2%.

Article Details

เนื้อหาและข่อมูลในบทความที่ลงตีพิมพ์ในวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม ถือเป็นข้อคิดเห็นและความรับผิดชอบของผู้เขียนบทความโดยตรง ซึ่งกองบรรณาธิการวารสารไม่จำเป็นต้องเห็นด้วย หรือว่าร่วมรับผิดชอบใด ๆ

บทความ ข้อมูล เนื้อหา รูปภาพ ฯลฯ ที่ได้รับการตีพิมพ์ในวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม ถือเป็นลิขสิทธิ์ของวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม หากบุคคล หรือหน่วยงานใดต้องการนำทั้งหมด หรือส่วนหนึ่งส่วนใดไปเผยแพร่ต่อ หรือเพื่อกระทำการใด ๆ จะต้องได้รับอนุญาต เป็นลายลักษณ์อักษรจากวารสารวิชาการ เทคโนโลยี พลังงาน และสิ่งแวดล้อม บัณฑิตวิทยาลัย วิทยาลัยเทคโนโลยีสยาม เท่านั้น

References

Lin, L. C. and Sharp, G. P., Quantitative and Qualitative Indices for the Plant Layout Evaluation Problem. European Journal of Operational Research, 1999. 116(1), p. 100-117.

Ho W., Integrated Analytic Hierarchy Process and Its Applications – A Literature Review. European Journal of Operational Research, 2008, 186, p. 211-228.

Yang T and Kuo C., A Hierarchical AHP/DEA Methodology for the Facilities Layout Design Problem. European Journal of Operational Research, 2003, 147, p. 128 -136.

Ertay T, Ruan D, and Tuzkaya UR., Integrating Data Envelopment Analysis and Analytic Hierarchy for the Facility Layout Design in Manufacturing Systems. Information Sciences, 2006, 176, p. 237-262.

Aguilar-Lasserre A. A., et al., An AHP-Based Decision-Making Tool for the Solution of Multiproduct Batch Plant Design Problem under Imprecise Demand. Computer & Operations Research, 2009, 36, p. 711-736.

Ishizaka A. and Labib A., Selection of New Production Facilities with the Group Analytic Hierarchy Process Ordering Method. Expert Systems with Applications, 2011, 38, p. 7317-7325.

Muther R. and Hales L. (2015). Systematic Layout Planning. 4th Edition. Management & Industrial Research Publications

Saaty, T. L. (1994). Fundamentals of Decision Making and Priority Theory with the AHP. Pittsburg: RWS Publications.

Saaty, T. L. (1980). The Analytic Hierarchy Process. McGraw-Hill, New York.

Gurcan, O.F., et al., Third Party Logistics (3PL) Provider Selection with AHP Application. In: 12th International Strategic Management Conference, ISMC 2016, 28-30 October 2016, p. 226-234.

Jharkharia, S. and R. Shankar, Selection of logistics service provider: An analytic network process (ANP) approach. Omega, 2007. 35(3), p. 274-289.