Degradation Factors of Semi-Synthetic Lubricant oil for Gasoline-CNG Engine

Keywords:

Semi-synthetic lubricant oil, compressed natural gas (CNG), gasoline, lubricant oildegradation, additive depletion, free radical, contaminationAbstract

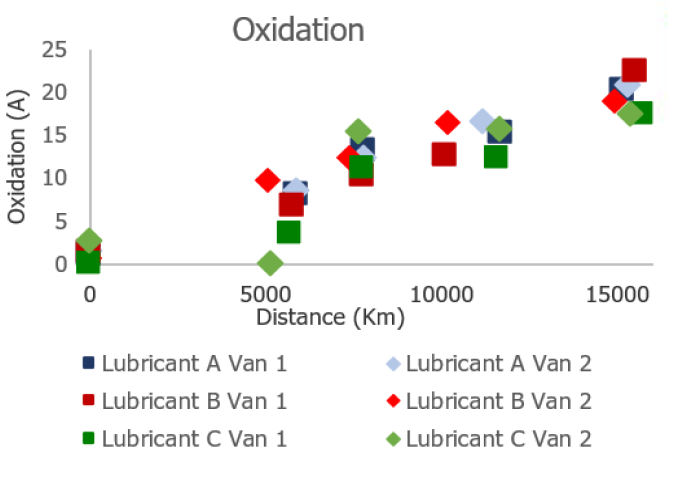

Compressed natural gas (CNG) as alternative energy has gained attention in public transport. CNG is clean energy, high octane, and less expensive than other fuels and can be operated in a dual-fuel engine system. This research studied various factors that affect the degradation of semi-synthetic engine lubricants for the gasoline-CNG engine. Samples were collected by distance lubricant oil analysis was conducted based on various ASTM methods. The kinematic viscosity (KV) analysis is an important property of Lubricant oil. It was measured at the structures of 40 and 100 °C. At 100 °C, the KV decreased from the heating phase, causing the intramolecular bonds to break, making the oil film thinner and leading to a catalytic oxidation reaction. The Fourier transform infrared (FTIR) spectroscopy showed that the lubricants undergo chemical changes in their properties due to increasing the carbonyl functional (C=O) concentration by oxidation product. The result indicated increased acid content and KV. It affects the corrosion of the internal engine parts. The total base number analysis indicates the cleaning agent performance of the lubricant. It was found that at a distance of over 15,000 km, the concentration of alkaline additive reduces half the amount of additive. This demonstrated that additives have been degraded from contaminations, such as dirt, water, metal, and soot.

References

Al Sheikh Omar, A., Motamen Salehi, F., Farooq, U., Morina, A., & Neville, A. (2021). Chemical and physical assessment of engine oils degradation and additive depletion by soot. Tribology International,160, 107054. https://doi.org/10.1016/j.triboint.2021.107054

ASTM International. (2019). Standard Test Method for Determination of Additive Elements in Lubricating Oils inductively Coupled Plasma Atomic EmissionSpectrometry.3, 1-3.

ASTM International Standards. (2000). Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity).9, 4-11.

ASTM International Standards. (2018). Standard Test Method for Base Number Determination by Potentiometric Hydrochloric Acid Titration.8, 1-8.

ASTM International Standards. (2019). Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry.24, 1-24.

Barman, B. (2002). Behavioral differences between group I and group II base oils during thermo-oxidative degradation. Tribology International,35(1), 15-26.

Goncalves, I. M., Murillo, M., & González, A. M. (1998). Determination of metals in used lubricating oils by AAS using emulsified samples. Talanta,47(4), 1033-1042.https://doi.org/10.1016/S0039-9140(98)00186-6

Guan, L., Feng, X., Xiong, G., & Xie, J. (2011). Application of dielectric spectroscopy for engine lubricating oildegradation monitoring. Sensors and Actuators A: Physical,168(1), 22-29.

Heredia-Cancino, J., Ramezani, M., & Álvarez-Ramos, M. (2018). Effect of degradation on the tribological performance of engine lubricants at elevated temperatures. Tribology International,124, 230-237.

Karluk, A. A., Ekim, S. D., Baytekin, B., & Tarik Baytekin, H. (2022). Online lubricant degradation monitoring using contact charging of polymers. Applied Surface Science,584, 152593. https://doi.org/10.1016/j.apsusc.2022.152593

Kumar, S., Mishra, N., & Mukherjee, P. (2005). Additives depletion and engine oil condition–a case study. Industrial Lubrication and Tribology, 50(2), 69-72.

Lara, R. F., Azcarate, S. M., Cantarelli, M. Á., Orozco, I. M., Caroprese, M. E., Savio, M., & Camiña, J. M. (2015). Lubricant quality control: A chemometric approach to assess wear engine in heavy machines. Tribology International,86, 36-41.https://doi.org/10.1016/j.triboint.2015.01.009

Macián, V., Tormos, B., García-Barberá, A., & Tsolakis, A. (2021). Applying chemometric procedures for correlation the FTIR spectroscopy with the new thermometric evaluation of Total Acid Number and Total Basic Number in engine oils. Chemometrics and Intelligent Laboratory Systems,208,104215.https://doi.org/10.1016/j.chemolab.2020.104215

Maguire, E. (2010). Monitoring of Lubricant Degradation with RULER and MPC[Unpublished master's thesis]. Linköping University.

Notay, R. S., Priest, M., & Fox, M. F. (2019). The influence of lubricant degradation on measured piston ring film thickness in a fired gasoline reciprocating engine. Tribology International,129, 112-123.

Aucélio, R. Q., de Souza, R. M., de Campos, R. C., Miekeley, N., & da Silveira, C. L. P. (2007). The determination of trace metals in lubricating oils by atomic spectrometry. Spectrochimica Acta Part B: Atomic Spectroscopy, 62(9), 952-961.

Salem, S., Salem, A., & Babaei, A. A. (2015). Application of Iranian nano-porous Ca-bentonite for recovery of waste lubricant oil by distillation and adsorption techniques. Journal of Industrial and Engineering Chemistry,23, 154-162.https://doi.org/10.1016/j.jiec.2014.08.009

Sneha, E., Karthik, G. V. S., Thampi, A. D., Krishna, A., Revikumar, A., & Rani, S. (2021). Experimental and quantum chemical investigation of bio-fuels/lubricants for its oxidative stability. Journal of Molecular Liquids,340, 117-292.https://doi.org/10.1016/j.molliq.2021.117292

Zheng, F., Zhang, H., Yin, H., Fu, M., Jiang, H., Li, J., & Ding, Y. (2022). Evaluation of real-world emissions of China V heavy-duty vehicles fueled by diesel, CNG, and LNG on various road types. Chemosphere,303,135-137.https://doi.org/10.1016/j.chemosphere.2022.135137

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2023 Journal of Applied Science and Emerging Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.