Enhancement of Bagasse Cellulose-Poly(Lactic Acid) Interaction Using Poly(Ethylene Glycol) Chain Extender

Keywords:

transesterification, biodegradable packaging, biocomposite, structural modificationAbstract

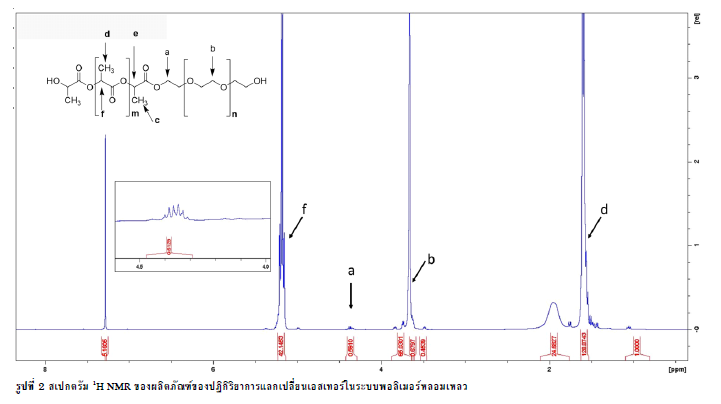

Sugar cane bagasse pulp is one ofthe most abundant natural cellulose fiber available as by-product from sugar industries of Thailand. The bagasse fiber, not only renewable but also biodegradable, provides a huge potential in reinforcement of bioplastic such as poly(lactic acid) (PLA) to be used for biodegradable food packaging. However, direct biocomposite fabrication using melt mixing process requires high blending temperature and massive amount of torque due to difference in polarity of the two components. In this study, trans-esterification between PLA and poly(ethylene glycol) (PEG) has been proved possible in both melt-mixing and compression moulding processes at 180 oC for 10 minutes as well as in the compression mouldingof bleached bagasse pulp (BBP) partially pre-coated with PEG and PLA. In addition, the obtained copolymer PLA-b-PEG showed high improved of reinforcement in the BBP/PLA/PEG composite when PEG content is 10-20% by weight and BBP content not more than 5-10%were used.

References

Bledzki, A.K.,Jazkiewincz, A.,& Scherzer, D. (2009).Mechanical properties of PLA composites with man-made cellulose and abaca fibres.Composites: Part A, 40, 404-412.

Bras, J., Hassan, M.L., Bruzesse,C., Hassan E.A., El-Wakil N.A.,& Dufresne, A. (2010).Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites.Industrial Crops and Products, 32, 627-633.

Conn, R.E., Kolstad, J.J.,Borzelleca, J.F.,Dixler, D.S.,Filer, L.J.,& Ladu, B.N.(1995).Safety assessment of polylactide (PLA) for use as a food-contact polymer.Food and Chemical Toxicology, 33(4), 273-283. https://doi.org/10.1016/0278-6915(94)00145-E

Garlotta, D. A.(2001).Literature Review of Poly(Lactic Acid). Journal of Polymers and the Environment,9, 63-84. https://doi.org/10.1023/A:1020200822435

Graupner, N., Herrmann, A.S.,& Mussig, J. (2009).Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas.Composites: Part A,40, 810-821.

Huda, M.S., Drzal, L.T., Mohanty A.K.,& Misra, M. (2008).Effect of fiber surface-treatments on the properties of laminated biocompositesfrom poly(lactic acid) (PLA) and kenaf fibers.Composites Science and Technology, 68, 424-432.

Jem, K.J.,& Tan, B. (2020). The development and challenges of poly (lactic acid) and poly (glycolic acid).Advanced Industrial and Engineering Polymer Research, 3(2), 60-70.https://doi.org/10.1016/j.aiepr.2020.01.002

Jonoobi M., Harun, J., Mathew, A.P.,& Oksman, K. (2010).Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion.Composite Science and Technology, 70, 1742-1747.

Kaplan, D.L. (1998).Biopolymers from renewable resources.Heidelberg, Germany: Springer-Verlag.

Lim, L.-T., Auras, R.,& Rubino, M. (2008).Processing technologies for poly(lactic acid).Progress in Polymer Science, 33, 820-852.

Maglio, G., Migliozzi, A., & Palumbo, R. (2003). Thermal properties of di-and triblock copolymers of poly(l-lactide) with poly(oxyethylene) or poly(ε-caprolactone). Polymer, 44,369–375.

Martino, V.P., Ruseckaite, R.A.,& Jiménez, A. (2006). Thermal and mechanical characterization of plasticized poly (L-lactide-co-D,L-lactide) films for food packaging. Journal of Thermal Analysis and Calorimetry,86(3), 707–712. https://doi.org/10.1007/s10973-006-7897-3

Nakagaito, A.N. Fujimura, A. Sakai, T. Hama Y.,& Yano, H. (2009).Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process.Composites Science and Technology, 69, 1293-1297.

Nofar, M., Sacligil, D., Carreau, P. J., Kamal, M. R., & Heuzey, M. C. (2019).Poly (lactic acid) blends: Processing, properties and applications. International Journal of Biological Macromolecules, 125, 307-360. https://doi.org/10.1016/j.ijbiomac.2018.12.002

Okubo, K., Fujii T.,& Thostenson, E.T. (2009).Multi-scale hybrid biocomposite: Processing and mechanical characterization of bamboo fiber reinforced PLA with microfibrillated cellulose.Composites: Part A, 40, 469-475.

Piorkowska,E., Kulinski,Z., Galeski,A.,& Masirek,R. (2006), Plasticization of semicrystalline poly(l-lactide) with poly(propylene glycol).Polymer, 47(20), 7178-7188. https://doi.org/10.1016/j.polymer.2006.03.115

Sheth, M., Kumar, R.A., Davé, V., Gross, R. A.,&, McCarthy, S.P. (1997).Biodegradable polymer blends of poly(lactic acid) and poly(ethylene glycol).Journal of Applied Polymer Science, 66(8),1495-1505.

Shin, H., Thanakkasaranee, S., Sadeghi, K.,& Seo, J. (2022).Preparation and characterization of ductile PLA/PEG blend films for eco-friendly flexible packaging application.Food Packaging and Shelf Life, 34, 100966-100975. https://doi.org/10.1016/j.fpsl.2022.100966

Sirisinha K., Wirasate S., Sirisinha C.,& Wattanakrai N. (2022).One-Pot Reactive Melt Recycling of PLA Post-Consumer Waste for the Production of Block Copolymer Nanocomposites of High Strength and Ductility.Polymers, 14(17), 3642-3654. https://doi.org/10.3390/polym14173642

Suryanegara, L., Nakagaito, A.N.,& Yano, H. (2009).The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA-composites.Composites Science and Technology, 69, 1187-1192.

Vroman, I.,& Tighzert, L.(2009).Biodegradable Polymers.Materials, 2, 307-344. https://doi:10.3390/ma2020307

Xiao, R. Z., Zeng, Z. W., Zhou, G. L., Wang, J. J., Li, F. Z., & Wang, A. M. (2010). Recent advances in PEG-PLA block copolymer nanoparticles. International Journal of Nanomedicine, 5, 1057–1065. https://doi.org/10.2147/IJN.S14912

Xu, G., Chen, S., Yan, X., Yang, C.,& Chen, Z. (2016). Synthesis and Hydrophilic Performance of Poly(Lactic Acid)-Poly(Ethylene Glycol) Block Copolymers. American Journal of Analytical Chemistry, 7, 299-305. http://doi: 10.4236/ajac.2016.73028

Zang, H., Xia, H., Wang, J.,& Li, Y. (2009). High intensity focused untrasound-responsive release behavior of PLA-b-PEG.Journal of Controlled Release, 139, 31-39.

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2023 Journal of Applied Science and Emerging Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.