Study on the properties and cracked heels treatment of foam insole made from urea filled natural rubber latex

Keywords:

Urea, Natural rubber latex, Rubber foam, Insole, Heel crackedAbstract

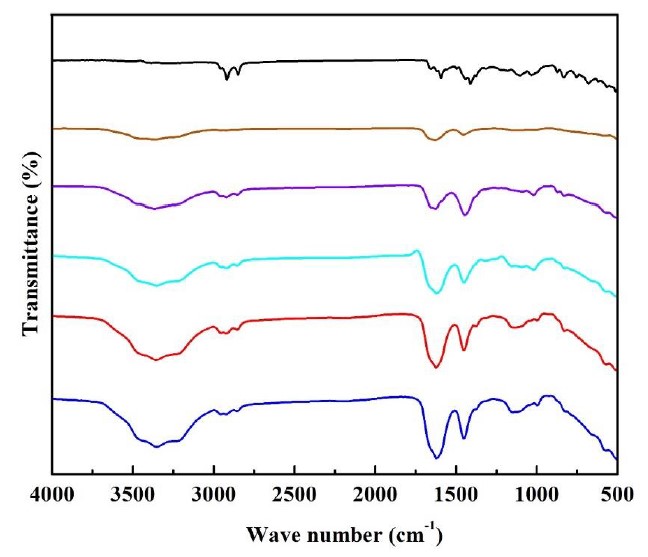

This research studied preparation of natural rubber foam adding urea cosmetic grade for producing heel pads prototype and further investigation a foot care treatment with 35 volunteers. It was found that the optimum latex compound formulation consisted of CaCO3 30 phr and urea 12 phr. They were blended for 15 minutes at room temperature. The foam exhibited the optimum properties with 0.80±0.002 g/cm3 and 1.71±0.20 kPa of density and stress at 25% compressive, respectively. Moreover, an increase of urea leaded to decreasing trends of both density and stress of the prototype products which is due mainly to a more releasing of carbon dioxide gas. The ATR-FTIR technique was used to determine the quantity of urea by generating calibration curve in one peak and one base modes. The prototype products were used by the volunteer for 1- 4 weeks. It was found that the urea contents slightly decreased to 133.41±11.87, 77.23±24.86, 59.21±20.56 and 20.07±11.26 mg from week 1-4, respectively. The practical satisfaction tests were done with 35 volunteers who have suffered with heel broken. The statistical analysis results combined with photo was found that the cracked heels were able to improve after having the treatment for 1 week and the skin have been better in the next week compared to that of using the controlled sample without urea. This was confirmed by the statistical analysis 2 type relation t-test at level of significance 0.05 in overall satisfaction before and after using for 4 weeks. The results found that there was no difference (t-prob=0.173) after 1 week of treatment but there were significant differences after treating for 2, 3 and 4 weeks.

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2022 The Journal of Applied Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.