Effect of soybean preparation methods on physicochemical and sensory properties of soy milk and effect of drying temperatures and maltodextrin concentrations on quality of spray-dried soy milk powder

Keywords:

spray drying, soy bean preparation, soy milk powder, maltodextrin, hot air temperatureAbstract

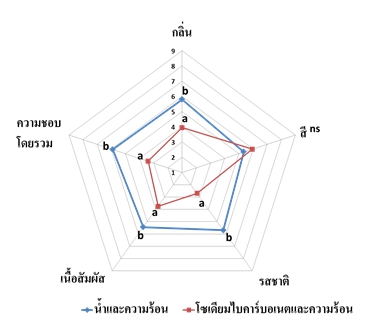

The research aimed to study effect of soybean preparation methods (method 1 using water and heat, and method 2 using sodium bicarbonate and heat) on physicochemical and sensory properties of soy milk. It was found that soymilk prepared by method 1 was contained higher content of protein, carbohydrate, and panelists' acceptance scores in terms of odor, taste, texture, and overall liking than method 2. The moisture, protein, carbohydrate fat and ash content of soy milk which prepared from method 1 were 90.71, 3.83, 3.41, 1.73, 0.32% (wet basis), respectively. Thereafter, the soy milk which prepared from method 1 was spray dried. The effects of inlet hot air temperature (150, 160, and 170 °C) and maltodextrin concentration (9, 12, and 15% (w/v) on physicochemical properties of soy milk powder were studied. Maltodextrin concentration of 15% (w/v) and the inlet hot air temperature of 160 and 170 °C, resulting in soybean milk powder having the highest solubility index (1 ml) and stability value (31%). Therefore, the best condition for production of spray-dried soybean powder which gave the highest solubility index and stability value while the lowest energy consumption was using maltodextrin 15% (w/v) and inlet hot air temperature at 160 °C.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 The Journal of Applied Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.