Sustainable mortar and concrete made from palm oil boiler clinker aggregate comprising rice husk ash and calcium bentonite: Compressive strength and durability assessment

Keywords:

palm oil boiler clinker, rice husk ash, calcium bentonite, compressive strength, sulfuric acid resistance, chloride ion permeabilityAbstract

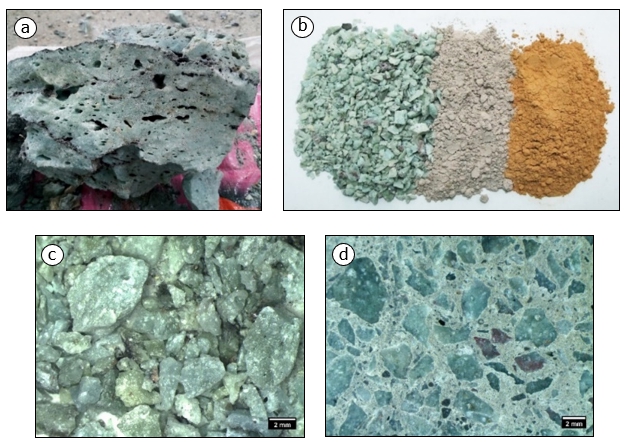

This research was conducted to assess the performances of mortars and concretes made from palm oil boiler clinker aggregate (POBC) blending with rice husk ash (RHA) and calcium bentonite (CB). These blends were used to substitute by weight of ordinary Portland cement (OPC) in the combined proportions from 0 to 30%. The POBC mortars were examined for compressive strength, water absorption, sulfuric acid resistance, and microstructural characterization at the age of 7, 28, and 56 days. Subsequently, the POBC concretes were tested for rapid chloride ion permeability and capillary absorption at 28 and 56 days of curing ages. As a result, the 56-day POBC mortar with the optimum blending of 5% CB and 15% RHA provided the greatest compressive strength of 48 MPa as well as revealed denser microstructure observed under scanning electron microscope (SEM) and greater durability against sulfuric acid attack which surpassed those of the POBC mortar without CB and RHA. Proportionately, the incorporation of 5-10% CB with 15-20% RHA to POBC concrete cured up to 56 days possessed greater durability performances by reducing the chloride ion permeability from moderate to very low ranges as well as lessening capillary absorption. The practical implications of this study are that the POBC could be potentially used in the building sector as a substitute to the conventional aggregates. In addition, the use of CB and RHA could be possibly replaced cement in the optimum proportions without compromising the strength and durability to produce efficiently sustainable POBC mortar and concrete.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 The Journal of Applied Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.