Effect of chitosan loading on structural and physical properties of polyvinylpyrrolidone/chitosan composites using simple casting process

DOI:

https://doi.org/10.55674/cs.v17i2.260988Keywords:

polyvinylpyrrolidone, chitosan, polymer compositesAbstract

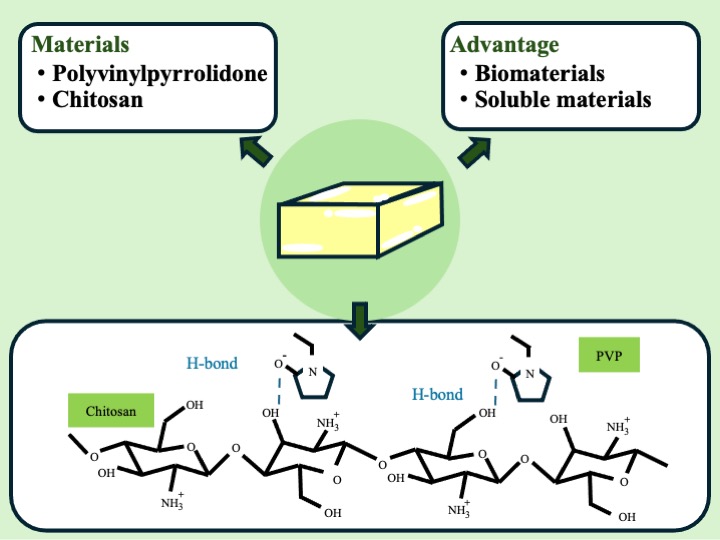

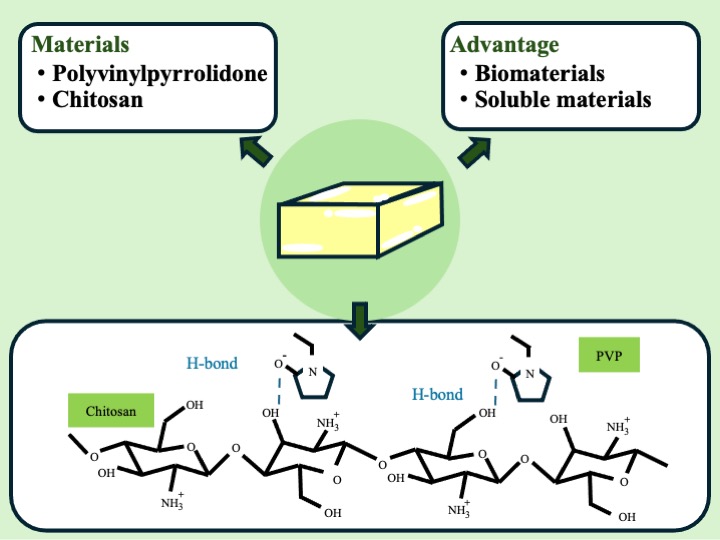

This research focused on the development of polymer composite materials for dissolving needles applications. Polyvinylpyrrolidone (PVP) was selected as the matrix phase, with chitosan (CS) chosen as the reinforcement phase due to its unique ability to absorb various substances and maintain stability in a room-temperature environment. Acetic acid was used as a dissolving agent for the chitosan suspension. A 30% w/v PVP solution was prepared in deionized water under magnetic stirring. Subsequently, chitosan powder was dissolved in acetic acid (2 M) at a 1.00 : 1.75 mole ratio using an ultrasonic process. Different weight ratios of the chitosan suspension (0.0, 0.5, 1.0, 2.0, 5.0, and 10.0 wt%) were added to PVP matrix under continuous stirring at 200 rpm for 30 min. to achieve a homogenous suspension. Each PVP/CS suspension was then cast into a silicone mold and dried at 40 ºC in the oven. Examining the structural properties of the PVP/CS composite samples under an optical microscope revealed a well-dispersed arrangement of CS particles within the PVP matrix. In the chemical structure analysis using Fourier transform infrared (FTIR) spectroscopy, the spectra of the PVP composites with different CS ratios exhibited identical patterns for all the samples, indicating a correlation with the same phases in the precursor materials. Furthermore, the optimized ratio of 1 wt% chitosan loading in the PVP/CS composites achieved a balance between enhanced mechanical property and reduced solubility, influenced by the distribution of CS particles within the PVP structure. Moreover, the presence of hydrogen bonds between the NH2 groups in chitosan and the C=O groups in PVP plays a key role in mechanical enhancement and soluble time.

GRAPHICAL ABSTRACT

HIGHLIGHTS

- Polymer composites for soluble materials

- Polymer composite film by simple casting process

- Enhancing hardness property by PVP/CS polymer composites

References

E.C. Tarring, I. Durance, M.J. Harbottle, R Lucas, D.S. Read, B.D. Ward, Water soluble polymers: Emerging contam-inants detected, separated and quantified by a novel GPC/MALDI-TOF method, Environ. Pollut. 340(1) (2024) 122888. 10.1016/j.envpol.2023.122888.

V.G. Kadajji, G.V. Betageri, Water Soluble Polymers for Pharmaceutical Applications, Polymers. 3(4) (2011) 1972-2009. 10.3390/polym3041972.

M.M. Jayakody, K.G. Kaushani, M.P.G. Vanniarachchy, I. Wijesekara, Hydrocolloid and water soluble polymers used in the food industry and their functional properties: a review, Polym. Bull. 80(4) (2022) 3585-3610. 10.1007/s00289-022-04264-5.

K. Duis, T. Junker, A. Coors, Environmental fate and effects of water-soluble synthetic organic polymers used in cosmetic products, Environ. Sci. Eur. 33(1) (2021) 21. 10.1186/s12302-021-00466-2 .

T. Berninger, N. Dietz, O.G. Lopez, Water-soluble polymers in agriculture: xanthan gum as eco-friendly alternative to synthetics, Microb. Biotechnol. 14(5) (2021) 1881-1896. 10.1111/1751-7915.13867.

Y.S. Ye, J.R., B.J. Hwang, Water Soluble Polymers as Proton Exchange Membranes for Fuel Cells. Polymers. 4(2) (2012) 913-963. 10.3390/polym4020913.

M. Shahmiri, N.A. Ibrahim, W.M.Z.W. Yunus, K. Shameli, N. Zainuddin, H. Jahangirian, Synthesis and Characterization of CuO Nanosheets in Polyvinylpyrrolidone by Quick Precipitation Method, Adv. Sci. Eng. Med. 5(3) (2013) 193-197. 10.1166/asem.2013.1227.

N. Mounayer, S. Shoshani, E. Afrimzon, T.I. Vul, M. Topaz, E. Banin, S. Margel, Encapsulation of Hydrogen Peroxide in PVA/PVP Hydrogels for Medical Applications, Gels. 11(1) (2025) 1-21. 10.3390/gels11010031.

J.T. Yeh, C.L. Chen, K.S. Huang, Y.H. Nien, J.L. Chen, P.Z. Huang, Synthesis, characterization, and application of PVP/chitosan blended polymers, J. Appl. Polym. Sci. 101(2) (2006) 885-891. 10.1002/app.23517.

A. Aryaeia, A.H. Jayatissaa, A.C. Jayasuriya, Nano and micro mechanical properties of uncross-linked and cross-linked chitosan films, J. Mech. Behav. Biomed. Mater. 5(1) (2012) 82-89. 10.1016/j.jmbbm.2011.08.006.

T.A. Ahmed, B.M. Aljaeid, Preparation, characterization, and potential application of chitosan, chitosan derivatives, and chitosan metal nanoparticles in pharmaceutical drug delivery, Drug Des Devel Ther. 10 (2016) 483-507. 10.2147/DDDT.S99651.

A. Khalid, H.S. Sarwar, M. Sarfraz, M.F. Sohail, A. Jalil, Y.A.B. Jardan, R. Arshad, I. Tahir, Z. Ahmad, Formulation and characterization of thiolated chitosan/polyvinyl acetate based microneedle patch for transdermal delivery of dydrogesterone, Saudi Pharm. J. 31(5) (2023) 669-677. 10.1016/j.jsps.2023.03.007.

J.H. Tay, Y.H. Lim, M. Zheng, Y. Zhao, W.S. Tan, C. Xu, U. Ramamurty, J. Song, Development of hyaluronic acid-silica composites via in situ precipitation for improved penetration efficiency in fast-dissolving microneedle systems, Acta Biomater. 172 (2023) 175-187. 10.1016/j.actbio.2023.10.016.

M. Voronova, N. Rubleva, N. Kochkina, A. Afineevskii, A. Zakharov, O. Surov, Preparation and characterization of polyvinylpyrrolidone/cellulose nanocrystals composites, Nanomaterials. 8(12) (2018). 10.3390/nano8121011.

R. Poonguzhali, S.K. Basha, V.S. Kumari, Synthesis and characterization of chitosan/poly (vinylpyrrolidone) biocomposite for biomedical application, Polym. Bull. 74(2017) 2185–2201. 10.1007/s00289-016-1831-z.

T. Gasti, V.D. Hiremani, S.P. Sataraddi, V.N. Vanjeri, N.Goudar, S.P. Masti, R.B. Chougale, R.B. Malabadi, UV screening, swelling and in-vitro cytotoxicity study of novel chitosan/poly (1-vinylpyrrolidone-co-vinyl acetate) blend films, Chem. Data Collect. 33 (2021) 100684.

Joongpun P, Khiaomang K, Seo M. Improvement of Hardness Properties of Natural Microfibers: Cotton, Kapok, and Banana as Filler-reinforced Natural Rubber Composites, Thai J. Nanosci. Nanotechnol. 7(2) (2022) 10-23.

P.S. Espinel, D.S. Otuna-Hernández, R. Davies , L. Spencer, H. Rodríguez . Chitosan and PVP: Versatile Biopolymers for Drug Delivery and Advanced Materials, Bionatura journal. 1(3) (2024) 2. 10.70099/BJ/2024.01.03.2.

P. Gupta, V.K. Kakumanu, A.K. Bansal. Stability and solubility of celecoxib-PVP amorphous dispersions: a molecular perspective, Pharm Res. 21(10) (2004) 1762-1769. 10.1023/b:pham. 0000045226.42859.b8.

M. Zeng, H. Xiao, X. Zhang, X. Sun, C. Qi, B. Wang, A Novel Chitosan /Polyvinyl Pyrrolidone (CS/PVP) Three -Dimensional Composite and Its Mechanism of Strength Improvement, J. Macromol. Sci., Part B. 50(7) (2011) 1413-1422.10.1080/00222348.2011.562072.

J. Zhang, B. Yuan, H. Ren. Synthesis and Characterization of PVP/Tb4/3L•7H2O Luminescent Complex, IOP Conf. Ser. Environ, Earth Sci. 170(3) (2018) 032043. 10.1088/1755-1315/170/3/032043.

Y. Cao, C. Shen, Z. Yang, Z. Cai, Z. Deng, D. Wu, Polycaprolactone/polyvinyl pyrrolidone nanofibers developed by solution blow spinning for encapsulation of chlorogenic acid, Food qual. saf. 6(2022).10.1093/fqsafe/fyac014.

R. Kumar, B. Rai, G. Kumar, A Simple Approach for the Synthesis of Cellulose Nanofiber Reinforced Chitosan/PVP Bio Nanocomposite Film for Packaging, J. Polym. Environ. 27(12) (2019) 2963-2973. 10.1007/s10924-019-01588-8.

S. Kumar, J. Koh, Physiochemical, optical and biological activity of chitosan-chromone derivative for biomedical applications, Int. J. Mol. Sci. 13(5) (2012) 6102-6116. 10.3390/ijms 13056102.

J. Zawadzki, H. Kaczmarek, Thermal treatment of chitosan in various conditions, Carbohydr. Polym. 80(2) (2010) 394-400. 10.1016/j.carbpol. 2009.11.037.

J. Rao, C. Shen, Z. Yang, O.A. Fawole, J. Li, D. Wua, K. Chen, Facile microfluidic fabrication and characterization of ethyl cellulose/PVP films with neatly arranged fibers, Carbohydr. Polym. 292(2022) 119702. 10.1016/j.carbpol.2022.119702.

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2025 Creative Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.