Optimization of friction stir spot welding between aluminium alloys and titanium alloy by the Taguchi method

DOI:

https://doi.org/10.55674/snrujst.v14i3.245169Keywords:

Friction Stir Spot Welding, Titanium Alloy, Taguchi methodAbstract

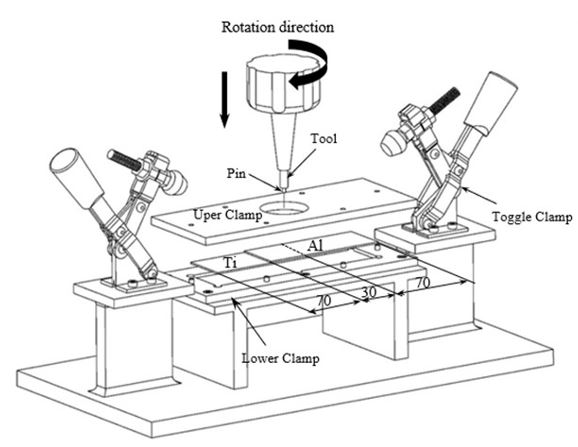

This research investigated the shear force of dissimilar welding processes between Ti-4V-6Al titanium alloys and Al5052 aluminium alloy by friction stir spot welding (FSSW). The Taguchi L9 orthogonal was used in the experimental design. The welding process parameters are rotation speed (A), feeds (B), and dwell time (C). ANOVA analyzed the S/N ratio of shear force to determine the optimal parameters for statistically significant factors. In addition, analyze for process parameters on the response and the level of the indispensability factor, as well as predict and regression model for optimal tensile strength. The investigation revealed that the optimum parameters were A2B2C3, and the shear force was 2.84 kN. Furthermore, the experiment found that rotation speed and dwell time significantly on the shear force since both factors had a P-value of less than 0.05 (p ≤ 0.05). Therefore, rotation speed and dwell time parameters are the most critical parameters in the process at a 95% confidence level. On the other hand, an investigation of feeds demonstrates an insignificant shear force of the weld due to a P-value above 0.05 (p ≥ 0.05).

References

S. Ji, Z. Li, L. Zhang, Y. Wang, Eliminating the tearing defect in Ti-6Al-4V alloy joint by back heating assisted friction stir welding, Mater. Lett.188(1) (2017) 21 – 24.

Z. Yan, X. Liu, H. Fang, Effect of sheet configuration on microstructure and mechanical behaviors of dissimilar Al–Mg–Si/Al–Zn–Mg aluminum alloys friction stir

welding joints, J Mater Sci Technol. 32(12) (2016) 1378 – 1385.

J. Shen, Y. Li, T. Zhang, D. Peng, D. Wang, N. Xu, Preheating friction stir spot welding of Mg/Al alloys in various lap configurations, Sci. Technol. Weld. Join. 20(1) (2015) 1 – 10.

A.H. Plaine, A.R. Gonzalez, U.F.H. Suhuddin, J.F. dos Santos, N.G. Alcantara, The optimization of friction spot welding process parameters in AA6181-T4 and Ti6Al4V dissimilar joints, Mater. Des. 83(2015) 36 – 41.

C. Panwisawas, B. Perumal, R.M. Ward, N. Turner, R.P. Turner, J.W. Brooks, H.C. Basoalto, Keyhole formation and thermal fluid flow induced porosity during laser fusion welding in titanium alloys experimental and modelling, Acta Mater. 126 (2017) 251 – 263.

H. Shi, K. Chen, Z. Liang, F. Dong, T. Yu, X. Dong, L. Zhang, A. Shan, Intermetallic compounds in the banded structure and their effect on mechanical properties of Al/Mg dissimilar friction stir welding joints, J Mater Sci Technol. 33 (2016) 359 –366.

W. Yao, A. Wu, G. Zou, J. Ren, Formation process of the bonding joint in Ti/Al diffusion bonding, Mater. Sci. Eng. A 480(1) (2008) 456 – 463.

W. Yao, A. Wu, G. Zou, J. Ren, 5A06/TA2 diffusion bonding with Nb diffusion-retarding layers, Mater. Lett. 62(17) (2008) 2836 – 2839.

M. Kimura, S. Nakamura, M. Kusaka, K. Seo, A. Fuji, Mechanical properties of friction welded joint between Ti–6Al–4V alloy and Al–Mg alloy (AA5052), Sci. Technol. Weld. Join. 10(6) (2005) 666 – 672.

X.W. Yang, W.Y. Feng, W.Y. Li, Q. Chu, Y.X. Xu, T.J. Ma, W.B. Wang, Microstructure and mechanical properties of dissimilar pinless friction stir spot welded 2A12 aluminum alloy and TC4 titanium alloy joints, J. Cent. South Univ. Technol. 25(12) (2018) 3075 – 3084.

M. Asmael, T. Nasir, Q. Zeeshan, B. Safaei, O. Kalaf, A. Motallebzadeh, G. Hussain, Prediction of properties of friction stir spot welded joints of AA7075-T651/Ti-6Al-4V alloy using machine learning algorithms. Arch. Civ. Mech. Eng. 22(2) (2022) 1 – 19.

L. Zhou, M. Yu, Z. Jiang, F. Guo, H. Zhao, Y. Huang, X. Song, Influence of rotation speed on microstructure and mechanical properties of friction stir lap welded joints of AA 6061 and Ti6Al4V alloys, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. 50(2) (2019) 733 – 745.

Z. Ma, X. Sun, S. Ji, Y. Wang, Y. Yue, Influences of ultrasonic on friction stir welding of Al/Ti dissimilar alloys under different welding conditions, Int. J. Adv. Manuf. Technol. 112(9) (2021) 2573 – 2582.

Y. Yue, Z. Zhang, S. Ji, Z. Li, D. Yan, Friction stir lap welding of 6061-T6 Al to Ti-6Al-4V using low rotating speed, Int. J. Adv. Manuf. Technol. 96(5) (2018) 2285 – 2291.

S. Prasomthong, S.Charoenrat, The optimization of welding hardfacing on wear resistance of FC-25 grey cast iron steel substrate by response surface methodology (RSM), SNRU. J. Sci. Tech. 14(2) (2022) 245154.

K. Nakowong, K. Sillapasa, Optimized Parameter for Butt Joint in Friction Stir Welding of Semi-Solid Aluminum Alloy 5083 Using Taguchi Technique, J. manuf. mater. process. 5(3) (2021) 88.

S. Prasomthong, O. Keattipong, The Optimization of Sheet Forming on Residual Stress and Surface Roughness with Two Point Incremental Forming Process (TPIF) of Aluminum Alloy Parts, Int. J. Appl. Sci. Eng. 16(4) (2022) 1 – 10.

S. Namkaew, S. Prasomthong, Application of Taguchi Method for Burnishing Process of AA5052 Aluminum Alloy by Studying the Optimization of Production, J. Ind. Tech. 17(1) (2021) 82 – 94.

A. Silachai, S. Prasomthong, Application of Taguchi method for friction stir spot welding process between aluminum alloy Al6061-T6 and high strength steel by studying the optimization of production machining parameters, RMUTSB Acad. J. 9(1) (2021) 69 – 82.

S. Vijayan, R. Raju, K. Subbaiah, N. Sridhar, S.R.K. Rao, Friction stir welding of Al-Mg alloy optimization of process parameters using Taguchi method, Exp Tech. 34(5) (2010) 37 – 44.

G.D. Urso, C. Giardini, The influence of process parameters and tool geometry on mechanical properties of friction stir welded aluminum lap joints, Int. J. Mater. Form. 3(1) (2010) 1011 – 1014.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 SNRU Journal of Science and Technology

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.