Napier Grass Pyrolysis: Kinetic and Thermodynamics Analysis

Main Article Content

Abstract

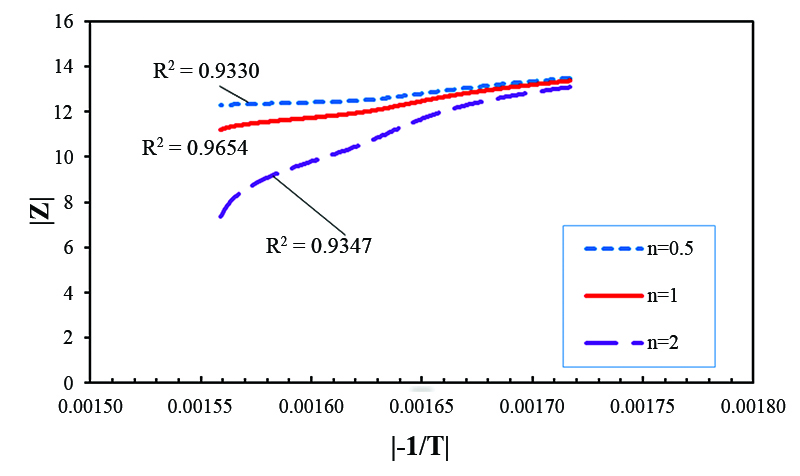

The pyrolysis behavior, kinetics and thermodynamics analysis of Napier grass were studied. A thermogravimetric analyzer (TGA) and differential thermal analyzer (DTA), at four heating rates: 5, 10, 20 and 30 oC/min were used in the experiments. Pyrolysis parameters were determined using model-fitting with the Coat-Redfern method. The results showed that the grass was roughly decomposed into moisture removal and volatiles release zones. The approximate peak temperature occurred in the major stage during 298 to 337 oC. The characteristic temperatures moved to a higher temperature during thermal degradation. The apparent activation energy and pre-exponential factor also increased with increasing heating rate. The positive values of enthalpies (ΔH), Gibbs free energies (ΔG) and the negative value of entropies (ΔS) exhibited that the Napier grass was endothermic but some exothermic reactions were also found, due to the presence of oxygen in its original components.

Article Details

References

Pyrolysis Products Characterization. Journal of Cleaner Production. Vol. 142, Part 4, pp. 1848-1866. DOI: 10.1016/j.jclepro.2016.11.099

[2] Collazzo, G. C., Broetto, C. C., Perondi, D., Junges, J., Dettmer, A., Dornelles Filho, A. A., Foletto, E. L., and Godinho, M. (2017). A Detailed Non-Isothermal Kinetic Study of Elephant Grass Pyrolysis from Different Models. Applied Thermal Engineering. Vol. 110, Issue 5, pp. 1200-1211. DOI: 10.1016/j.applthermaleng.2016.09.012

[3] Wang, D., Poss, J. A., Donovan, T. J., Shannon, M. C., and Lesch, S. M. (2002). Biophysical Properties and Biomass Production of Elephant Grass Under Saline Conditions. Journal of

Arid Environments. Vol. 52, Issue 4, pp. 447-456. DOI: 10.1006/jare.2002.1016

[4] Braga, R. M., Melo, D. A., Aquino, F. M., Freitas, J. C., Marcus A. F. M., Joana M. F. B., and Maria S. B. F. (2014). Characterization and Comparative Study of Pyrolysis Kinetics of the Rice Husk and the Elephant Grass. Journal of Thermal Analysis and Calorimetry. Vol. 115, Issue 2, pp. 1915-1920. DOI:10.1007/s10973-013-3503-7

[5] Richter, G. M., Riche, A. B., Dailey, A. G., Gezan, S. A., and Powlson, D. S. (2008). Is UK Biofuel Supply from Miscanthus Water-Limited?. Soil Use and Management. Vol. 24, Issue 3, pp. 235-245. DOI: 10.1111/j.1475-2743.2008.00156.x

[6] Cadoux, S., Riche, A. B., Yates, N. E., and Machet, J. M. (2012). Nutrient Requirements of Miscanthus x Giganteus: Conclusions from a Review of Published Studies. Biomass and

Bioenergy. Vol. 38, pp. 14-22. DOI: 10.1016/j.biombioe.2011.01.015

[7] Suntivarakorn, R., Treedet, W., Singbua, P., and Teeramaetawat, N. (2018). Fast Pyrolysis from Napier Grass for Pyrolysis Oil Production by Using Circulating Fluidized Bed Reactor:

Improvement of Pyrolysis System and Production Cost. Energy Reports. Vol.4, pp. 565-575. DOI: 10.1016/j.egyr.2018.08.004

[8] Basu, P. (2013). Biomass Gasification, Pyrolysis and Torrefaction. Practical Design and Theory. 2nd Edition Academic Press. p. 147

[9] Xu, Y. and Chen, B. (2013). Investigation of Thermodynamic Parameters in the Pyrolysis Conversion of Biomass and Manure to Biochars Using Thermogravimetric Snalysis. Bioresource Technology. Vol. 146, pp. 485-493. DOI: DOI: 10.1016/j.biortech.2013.07.086

[10] Chandrasekaran, A., Ramachandran, S., and Subbiah, S. (2017). Determination of Kinetic Parameters in the Pyrolysis Operation and Thermal Behavior of Prosopis Juliflora Using

Thermogravimetric Analysis. Bioresource Technology. Vol. 233, pp. 413-422. DOI: 10.1016/j.biortech.2017.02.119

[11] Magalhães, D., Kazanç, K., Riaza, J., Erensoy, S., Kabaklı, Ö., and Chalmers, H. (2017). Combustion of Turkish Lignites and Olive Residue: Experiments and Kinetic Modelling. Fuel.

Vol. 203, pp. 868-876. DOI: 10.1016/j.fuel.2017.05.050

[12] Gil, M.V., Casal, D., Pevida, C., Pis, J. J., and Rubiera, F. (2010). Thermal Behaviour and Kinetics of Coal/Biomass Blends During Co-Combustion. Bioresource Technology. Vol. 101, Issue 14, pp. 5601-5608. DOI: 10.1016/j.biortech.2010.02.008

[13] Freeman, E. S. and Carroll, B. (1958). The Application of Thermoanalytical Techniques to Reaction Kinetics: The Thermogravimetric Evaluation of the Kinetics of the Decomposition

of Calcium Oxalate Monohydrate. The Journal of Physical Chemistry. Vol. 62, Issue 4, pp. 394-397. DOI: 10.1021/j150562a003

[14] Manatura, K., Lu, J. -H., and Wu, K.-T. (2017). Thermal Decomposition and Kinetic Modeling of Torrefied Cryptomeria japonica in a CO2 Environment. Biofuels. pp. 1-11. DOI: 10.1080/17597269.2017.1302666

[15] Mesa-Pérez, J. M., Cortez, L. A. B., Marín-Mesa, H. R., Rocha, J. D., Peláez-Samaniego, M. R., and Cascarosa, E. (2014). A Statistical Analysis of the Auto Thermal Fast Pyrolysis of Elephant Grass in Fluidized Bed Reactor Based on Produced Charcoal. Applied Thermal Engineering. Vol. 65, Issue 1-2, pp. 322-329. DOI: 10.1016/j.applthermaleng.2013.12.072

[16] Yahiaoui, M., Hadoun, H., Toumert, I., and Hassani, A. (2015). Determination of Kinetic Parameters of Phlomis bovei de Noé Using Thermogravimetric Analysis. Bioresource Technology. Vol. 196, pp. 441-447. DOI: 10.1016/j.biortech.2015.07.082

[17] Quan, C., Li, A., and Gao, N. (2009). Thermogravimetric Analysis and Kinetic Study on Large Particles of Printed Circuit Board Wastes. Waste Management. Vol. 29, Issue 8, pp. 2353-2360. DOI: 10.1016/j.wasman.2009.03.020

[18] Chen, J., Wang, Y., Lang, X., Ren, X., and Fan, S. (2017). Evaluation of Agricultural Residues Pyrolysis Under Non-Isothermal Conditions: Thermal Behaviors, Kinetics, and Thermodynamics. Bioresource Technology. Vol. 241, pp. 340-348. DOI: 10.1016/j.biortech.2017.05.036

[19] Boonchom, B. and S. Puttawong. (2010). Thermodynamics and Kinetics of the Dehydration Reaction of FePO4•2H2O. Physica B: Condensed Matter. Vol. 405, No. 9, pp. 2350-2355

[20] Li, H., Niu, S. L., Lu, C. M., and Cheng, S. Q. (2015). Comparative Evaluation of Thermal Degradation for Biodiesels Derived from Various Feedstocks Through Transesterification.

Energy Conversion and Management. Vol. 98, pp. 81-88. DOI : 10.1016/j.enconman.2015.03.097