Effect of Silicon on Abrasive Wear Behavior of Heat-Treated 16% Cr - 2% Mo Cast Iron

Main Article Content

Abstract

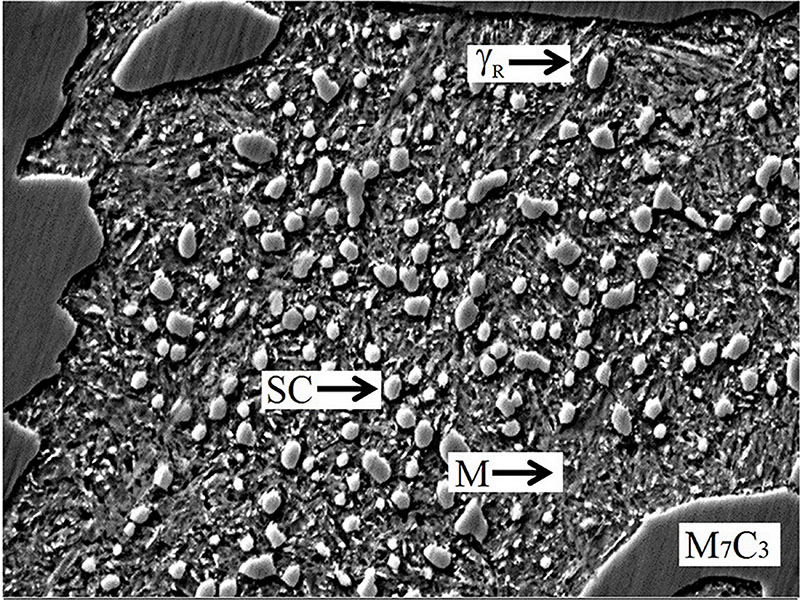

In this research, the effect of silicon (Si) on abrasive wear behavior of heat-treated 16 wt% Cr - 2 wt% Mo (as shown by %) cast iron was investigated. The specimens with

0.5 - 2.0 % Si were prepared. The specimens were annealed at 900 oC and then, hardened from 1,050 oC by oil quenching. The hardened specimens were tempered at 450, 500 and 550 oC, respectively. The abrasive wear resistance of specimens was evaluated using Suga abrasion tester. It was found that the linear relation between wear loss and wear distance was obtained in all specimens. The wear rate (Rw, mg/m) of specimen lowered as the hardness rose. The as-hardened specimens showed lower Rw value than tempered specimen did. In each heat treatment condition, the Rw value decreased progressively in the 1.5 % Si specimen and then increased gradually as the Si content increased. In the tempered state, the lowest Rw was obtained in the specimen tempered at 500 oC and the highest value of Rw was obtained in the specimen tempered at 550 oC. The specimen with 1.5 % Si was found to provide the lowest Rw or largest wear resistance.

Article Details

References

[2] Laird, G., and Powell, G. L. (1993). Solidification and Solid State Transformation Mechanisms in Si Alloyed High-Chromium White Cast irons. Metallurgical Transactions A. Vol. 24, Issue 4, pp. 981-988. DOI: 10.1007/BF02656520

[3] Park, J. L. (1985). Characteristic of As-cast and Sub-critical Heat Treated High-Chromium-Molybdenum White Irons for Thick-Section Casting. AFS Transactions. Vol. 86, pp. 93-102

[4] Sudsakorn, I., Prasonk, S., and Yasuhiro, M. (2006). Effect of Alloying Elements on Heat Treatment Behavior of Hypoeutectic High Chromium Cast Iron. Materials Transactions. Vol. 47, No. 1, pp. 72-81

[5] Bedolla-Jacuinde, A., Rainforth, M. W., and Mejia, I. (2013). The Role of Silicon in the Solidification of High-Cr Cast Irons. Metallurgical and Materials Transactions A. Vol. 44, Issue 2, pp. 856-872. DOI: 10.1007/s11661-012-1434-8

[6] Powell, G. L. F. (1996). Secondary Carbide Precipitation in an 18 wt% Cr - 1 wt% Mo White Iron. Journal of Materials Science. Vol. 31, Issue 3, pp. 707-711. DOI: 10.1007/BF00367889

[7] Pisizchai, K., Sudsakorn, I., Prasonk, S., and Yasuhiro, M. (2012). Effect of Silicon on Subcritical Heat Treatment Behavior and Wear Resistance of 16 wt% Cr Cast Iron with 2wt% Mo. Journal of Metals Materials and Minerals. Vol. 22, No. 2, pp. 89-95

[8] Sudsakorn, I., Attasit, C., Prasonk, S., and Yasuhiro, M. (2012). Two-Body and Three-body Types Abrasive Wear Behavior of Hypoeutectic 26 mass% Cr Cast Irons with Molybdenum. Materials Transactions. Vol. 53, No. 7, pp. 1258-1266

[9] Sudsakorn, I., Pisizchai, K., Sumpao, Y., and Yasuhiro, M. (2013). Effect of Repeated Tempering on Abrasive Wear Behavior of Hypoeutectic 16 mass% Cr Cast Iron with Molybdenum. Materials Transactions. Vol. 54, Issue 1, pp. 28-35. DOI: 10.2320/matertrans.M2012185

[10] Pisizchai, K., Sudsakorn, I., Keartisak, S., and Yasuhiro, M. (2016). The Effect of Sub-Critical Heat Treatment on Hardness, Retained Austenite and Abrasive Wear Resistance of Hypoeutectic 16 mass% Cr - 2 mass% Mo Cast Iron with Varying Vanadium Content. Materials Transactions. Vol. 57, No. 2, pp. 174-182

[11] ASTM Standard. (2004). ASTM International. West Conshohocken PA. United states