Optimum Fiber Content to Improve Compressive Strength of Glass Fibers Reinforced Cellular Lightweight Concrete for Hollow-core Precast Panel Walls

DOI:

https://doi.org/10.55674/ias.v14i1.255606Keywords:

Glass fiber, Cellular lightweight concrete, Compressive strengthAbstract

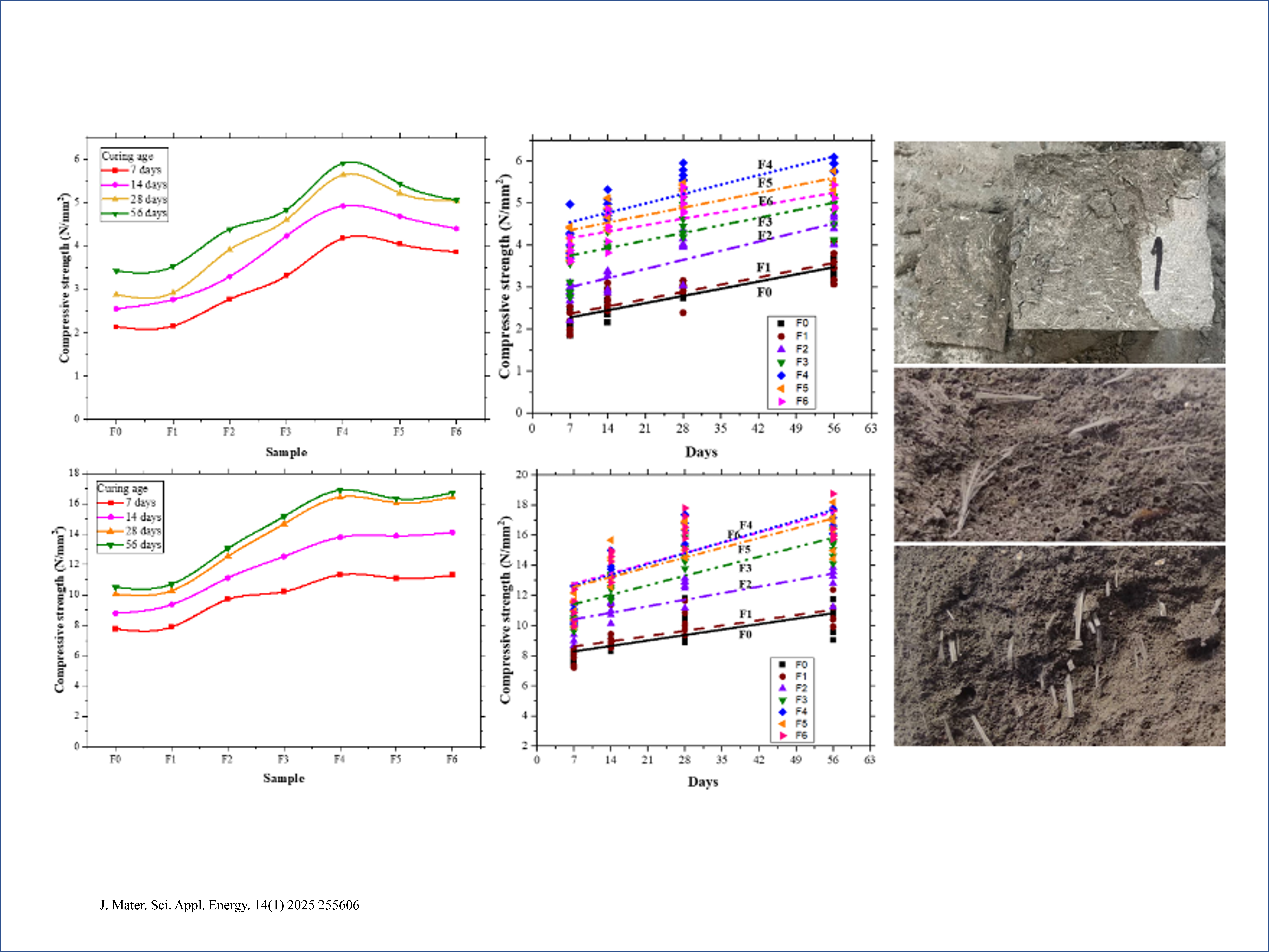

This study aimed to identify the optimal amount of glass fibers to enhance the compressive strength of Glass Fiber reinforced Cellular Lightweight Concrete (GF-CLC). The compressive strength of cellular lightweight concrete with densities of 1.20 × 102 kg m–3 and 1.60 × 102 kg m–3, containing different percentages (1%, 2%, 3%, 4%, 5%, and 6% by weight of cement) of glass fibers, was evaluated using BS EN 12390 Part 1 – 4 tests and compared with non-fiber specimens. The results indicate that 1% glass fiber reinforcement has an insignificant effect on compressive strength, while proportions of 2 – 4% by weight of cement lead to a significant increase in compressive strength at all stages of curing age. The optimum fiber content was found to be 4% by weight of cement, resulting in compressive strength improvements of 2 times and 1.60 times compared to non-fiber reinforced specimens at 1.20 × 102 kg m–3 and 1.60 × 102 kg m–3, respectively. However, adding more than 4% glass fiber by weight of cement leads to a decrease in compressive strength and a constant tendency at higher densities. Compressive strength tends to increase with increased density, curing time, and fiber content because more dense concrete provides higher bonding and pull-out strength between CLC and glass fiber, thereby enhancing the fiber’s performance in resisting tensile and shear forces in the cellular lightweight concrete particles, resulting in higher ultimate compressive strength.

References

Y. M. Amran, N. Farzadnia, A. Abang Ali, Properties and applications of foamed concrete; a review, Constr. Build. Mater. 101 (2015) 990 – 1005.

L. Chica, A. Alzate, Cellular concrete review: New trends for application in construction, Constr. Build. Mater. 200 (2019) 637 – 647.

J. L. Ruiz-Herrero, D. Velasco Nieto, A. López-Gil, A. Arranz, A. Fernández, A. Lorenzana, S. Merino, J. A. De Saja, M. Á. Rodríguez-Pérez, Mechanical and thermal performance of concrete and mortar cellular materials containing plastic waste, Constr. Build. Mater. 104 (2016) 298 – 310.

T. Thaveevouthi, G. Kaewkulchai, S. Bhokha, W. Puatasananon, Study of cellular lightweight concrete properties, Research report of National Research Council of Thailand (NRCT), 2020.

S. Wei, C. Yiqiang, Z. Yunsheng, M. Jones, Characterization and simulation of microstructure and thermal properties of foamed concrete, Constr. Build. Mater. 47 (2013) 1278 – 1291.

M. A. Othuman Mydin, Evaluation of the Mechanical Properties of Lightweight Foamed Concrete at Varying Elevated Temperatures, Fire 6 (2023) 53.

J. Vilches, M. Ramezani, T. Neitzert, Experimental investigation of the fire resistance of ultra lightweight foam concrete, Int. J. Adv. Eng. Appl. 1 (2012) 15 – 22.

X. Tan, W. Chen, J. Wang, D. Yang, X. Qi, Y. Ma, X. Wang, S. Ma, C. Li, Influence of high temperature on the residual physical and mechanical properties of foamed concrete, Constr. Build. Mater. 135 (2017) 203 – 211.

K. A. Mohd Sari, A. R. Mohammed Sani, Applications of foamed lightweight concrete, MATEC Web Conf. 97 (2017) 01097.

N. Narayanan, K. Ramamurthy, Structure and properties of aerated concrete: A review, Cem. Concr. Compos. 22 (2000) 321 – 329.

J. Yan, J. Wang, J. Liew, X. Qian, Applications of ultra-lightweight cement composite in flat slabs and double skin composite structures, Constr. Build. Mater. 111 (2016) 774 – 793.

I. K. Harith, Study on polyurethane foamed concrete for use in structural applications, Case Stud. Constr. Mater. 8 (2018) 79 – 86.

B. Chen, Z. Wu, N. Liu, Experimental research on properties of high-strength foamed concrete, J. Mater. Civ. Eng. 24(1) (2012) 113 – 118.

D. Panesar, Cellular concrete properties and the effect of synthetic and protein foaming agents, Constr. Build. Mater. 44 (2013) 575 – 584.

H. Akil, M. Omar, A. Mazuki, S. Safiee, Z. Ishak, A. A. Bakar, Kenaf fiber reinforced composites: A review, Mater. Des. 32(8-9) (2011) 4107 – 4121.

S. P. Yap, C. H. Bu, U. J. Alengaram, K. H. Mo, M. Z. Jumaat, Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete, Mater. Des. 57 (2014) 652 – 659.

R. F. Zollo, Fiber-reinforced concrete: An overview after 30 years of development, Cem. Concr. Compos. 19 (1997) 107 – 122.

C. G. Mendoza, M. O. Garcia, A. O. Sandoval, Hooked ends steel fibers effects on energy absorption capacity of concrete, ARPN J. Eng. Appl. Sci. 16(3) (2021) 1379 – 1385.

V. R. Shirodkar, A. N. Shaikh, Experimental investigation on the behavior of steel fiber and polypropylene fiber reinforced high strength concrete, Int. J. Eng. Res. Mech. Civ. Eng. 2456 – 1290 (2017) 29 – 34.

P. Balaguru, H. Najm, High-performance fiber-reinforced concrete mixture proportions with high fiber volume fractions, ACI Mater. J. 101(4) (2004) 281 – 286.

F. Akthar, J. Evans, High porosity (> 90%) cementitious foams, Cem. Concr. Res. 40(2) (2010) 352 – 358.

M. Hsie, C. Tu, P. Song, Mechanical properties of polypropylene hybrid fiber reinforced concrete, Mater. Sci. Eng. A 494(1 – 2) (2008) 153 – 157.

M. Song, N. Song, Y. Zhang, J. Wang, Mechanical properties of polypropylene-fiber-reinforced high-performance concrete based on the response surface method, Adv. Mater. Sci. Eng. 2022 (2022) Article ID 9802222, 1 – 18.

M. Tawfik, A. El-said, A. Deifalla, A. Awad, Mechanical properties of hybrid steel-polypropylene fiber reinforced high strength concrete exposed to various temperatures, Fibers 10 (2022) 53, 1 – 17.

M. A. Rasheed, S. S. Prakash, Mechanical behavior of sustainable hybrid-synthetic fiber reinforced cellular lightweight concrete for structural applications of masonry, Constr. Build. Mater. 98 (2015) 631 – 640.

A. Enfedaque, D. Cendón, F. Gálvez, V. Sánchez-Gálvez, Analysis of glass fiber reinforced cement (GRC) fracture surfaces, Constr. Build. Mater. 24(7) (2010) 1302 – 1308.

D. Chen, J. Deng, B. Cheng, Q. Wang, B. Zhao, New anticracking glass-fiber-reinforced cement material and integrated composite technology with lightweight concrete panels, Adv. Civ. Eng. 2021 (2021) Article ID 7447066, 1 – 17.

British Standards Institution, BS EN 12390-1:2012 Testing hardened concrete: Part 1 Shape, dimensions and other requirements for specimens and moulds, British Standards Institution, London (2012).

A. S. Sharma, G. Suhil, L. Visali, Influence of foam densities in cellular lightweight concrete, Int. J. Res. Appl. Sci. Eng. Technol. 5(4) (2017) 1986 – 1991.

K. Aini, M. Sari, A. Rahim, M. Sani, Applications of foamed lightweight concrete, MATEC Web Conf. 97 (2017) 1 – 5.

T. T. Nguyen, H. H. Bui, T. D. Ngo, G. D. Nguyen, Experimental and numerical investigation of influence of air-voids on the compressive behaviour of foamed concrete, Mater. Des. 130 (2017) 103-119.

T. Thaveevouthti, N. Sangtian, W. Puatasananon, I. Phannikul, Compressive strength of cellular lightweight concrete, UBU Eng. J. 13(2) (2019) 88 – 101.

British Standards Institution, BS EN 12390-2:2019 Testing hardened concrete: Part 2 Making and curing specimens for strength tests, British Standards Institution, London (2019).

British Standards Institution, BS EN 12390-3:2019 Testing hardened concrete: Part 3 Compressive strength of test specimens, British Standards Institution, London (2019).

British Standards Institution, BS EN 12390-4:2019 Testing hardened concrete: Part 4 Compressive strength – Specification for testing machines, British Standards Institution, London (2019).

P. Loijaroen, Development of Cellular Lightweight Concrete Mixed with Glass Fiber to Precast Wall Panel Product, Research reports to Thailand Science Research and Innovation, Thailand, Sakon Nakhon Rajabhat University. (2024).

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.