Comparison of Mechanical Properties of Biogas Packaging Materials

DOI:

https://doi.org/10.55674/ias.v14i1.252394Keywords:

Biogas, Factor of safety, Packaging materials, Specific strengthAbstract

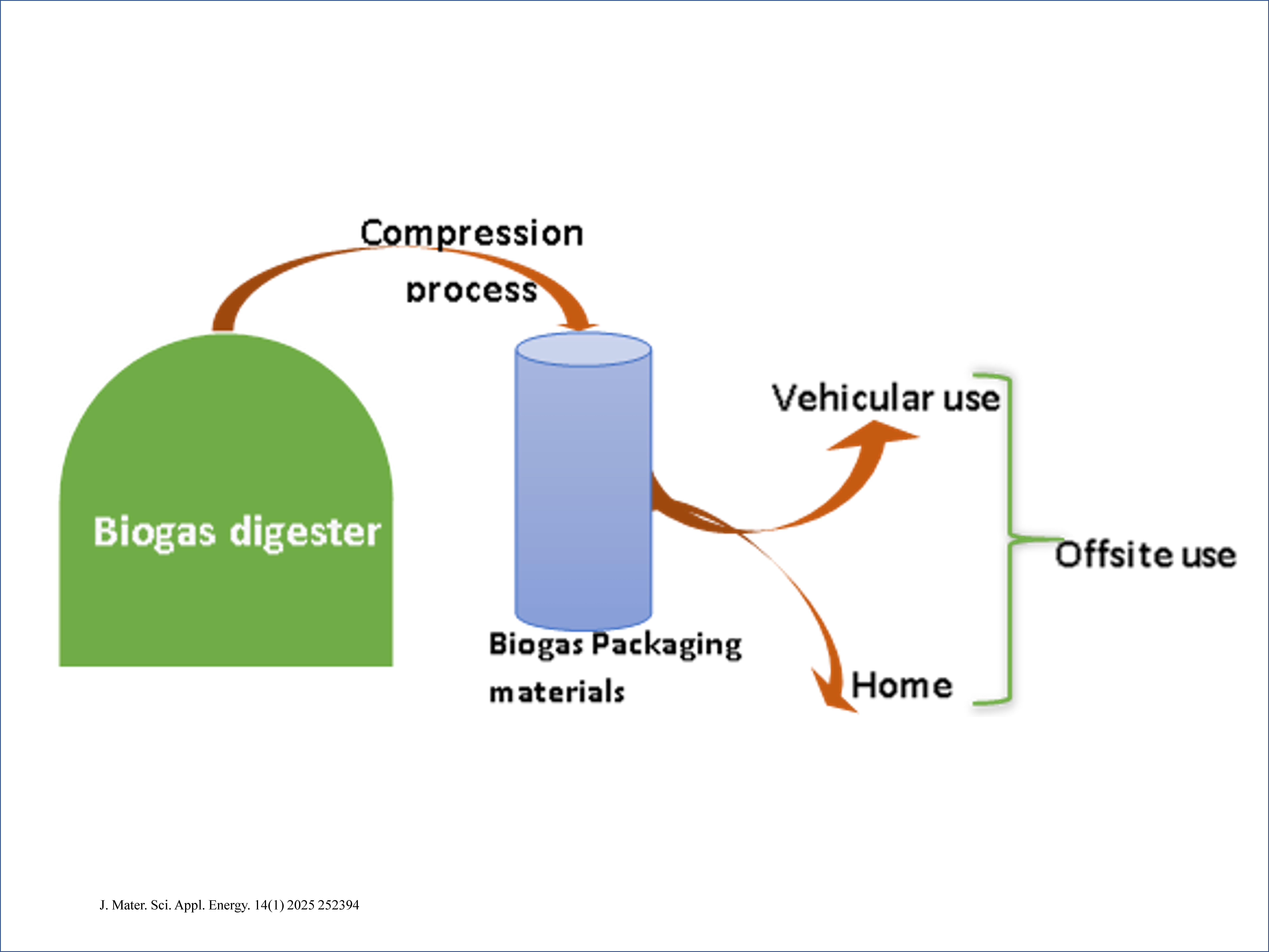

Initiatives of providing biogas onsite are futile without provision for offsite use. This study aims to compare the mechanical strength of materials for packaging biogas. To address the research problem, four materials were considered for the study, including: low-carbon steel, Aluminium, High-Density Polyethylene (HDPE) and fiberglass polyester composite. An experiment was carried out on each of the materials to find out the yield strength and ultimate tensile strength. Results indicate that, whereas steel ranks highest in many strength parameters, including; tensile strength, yield strength, factor of safety, and stress carrying capacity; fiberglass polyester composite closely follows in all measures, and has the highest value of specific strength of all the study materials; with over 58% more weight saving as compared to steel. This property explains the strength-to-weight ratio of a material; which is a key consideration for designing light and strong pressurized gas containers.

References

R. Walozi, B. Nabuuma, A. Sebiti, Application of low pressure water scrubbing technique for increasing methane content in biogas, Univers. J. Agric. 2 (2016) 60 – 65.

C. Özkale, C. Celik, A. C. Turkmen, E.S. Cakmaz, Decision analysis application intended for selection of a power plant running on renewable energy sources, Renew. Sustain. Energy Rev. 70 (2017) 1011 – 1021.

M. Torrijos, State of development of biogas production in Europe, Procedia Environ. Sci. 35 (2016) 881 – 889.

T. Kvist, N. Aryal, Alternative of biogas injection into the Danish gas grid system - A study from demand perspective, Chem. Eng. 2(3) (2018) 43.

P. Sangram, S. Khushal, C. Rohit, K. Nikhil, K. Balbheem, J. Bibin, Design of gas cylinder using composite material as per ASME, GJEIS. 9 (2017) 54 – 57.

B. Li, H. Wen, W. Zhou, J. Xu, B. Chen, Review: Porous metal - organic frameworks, Chem. 1(4) (2016) 557 – 580.

N. H. S, Ray, M. K. Mohanty, R. C. Mohanty, (2016), Biogas Compression and Storage System for Cooking Applications in Rural Households. IJRER. 6(2) (2016) 2 – 7.

CH. V. K. N. S. N. Moorthy, V. Srinivas, Stress analysis of domestic composite LPG cylinder using Classical Lamination Theory (CLT), Int. J. Eng. Technol. 7(4) (2018) 68 – 70.

W. Wang, Y. Ma, M. Yang, P. Jiang, F. Yuan, X. Wu, Strain rate effect on tensile behaviour for a high specific strength steel: From quasi-static to intermediate strain rates. Metals, 8(1) (2018) 11.

M, X. L. Wu, X. Yang, F. P. Yuan, Q. G. Xie, Y. D. Wang, E. Ma Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel, Heterostructured Materials. (2021) 721 – 747.

R. Frith, M. Stone, A proposed new pressure vessel design class, Int. J. Press. Vessels Pip. 139 (2016) 4 –11.

Z. Huda, E. H. Jie, A User-Friendly Approach to the Calculation of Safety Factor for Pressure Vessel Design–A Case Study, J. King Abdulaziz Univ. Arts Humanit. 27(1) (2016) 75 – 81.

A. Tripathi, A. Kumar, M. Chandrakar, Design and analysis of a composite cylinder for the storage of liquefied gases, IJSRD. 5(3) (2017) 871 – 876.

A. Asif Iqbal, D. M. Nuruzzaman, Effect of the Reinforcement on the Mechanical Properties of Aluminium Matrix Composite: A Review, Int. J. Appl. Eng. Res. 11(21) (2016) 10408 – 10413.

D. Varshney, K. Kumar, Application and use of different aluminium alloys with respect to workability, strength and welding parameter optimization, Ain Shams Eng. J. 12(1) (2021) 1143 – 1152.

S. Bandpatte, K. Shede, R. Chavan, N. Katkar, B. amanna, B. Jose, B. Design of gas cylinder using composite material as per ASME standards, GJES. 9(1) (2017) 54 – 57.

M. Dhanunjayaraju, T. L. R. Babu, (2015). Stress analysis of LPG cylinder with composites, IJAR. 1(12) (2015) 1042 – 1045.

K. Chalamaiah, V. Leelasarada, Analysis of LPG cylinder using carbon fiber reinforced plastic, IOSR-JMCE. 12(4) (2015) 17 – 28

L. Josimovi´c, S. Prvulovi´c, L. Djordjevi´c, I. Bicok, M. Bakator, V. Premˇcevski, U. Šarenac, D. Šeljmeši, Enhancing Biogas Plant Efficiency for the Production of Electrical and Thermal Energy, Appl. Sci. 14(13) (2024) 5858.

S. Bakkaloglu, & A. Hawkes, A comparative study of biogas and biomethane with natural gas and hydrogen alternatives, Energy Environ. Sci. 17(4) (2024) 1482 – 1496.

T. Luo, Z. Mei, A. Hove & K. Ju, Unlocking the potential of biogas systems for energy production and climate solutions in rural communities, Nat. Commun. 15(1) (2024) 5900.

A. Kajavatan, & U. Nitharsan, Contanerising biogas: Design and development of portable low-cost biogas bottling system, Int. J. Sci. Res. 6(4) (2016) 75 –79

Y. M. Ahmed, H. D. Lafta, A. A. A. Rahman, & B. T. Salih, Experimental study of the performance of base metal and welding line of the household LPG cylinder manufactured in Kurdistan Region, Int. J. Manuf. Eng. 4(3) (2019) 116 – 123.

M. Amjadi, & A. Fatemi, Tensile behaviour of high-density polyethylene including the effects of processing technique, thickness, temperature, and strain rate, Polymers. 12(9) (2020) 1857.

F. Kartal, Evaluation of explosion pressure of portable small liquefied petroleum gas cylinder. Process Saf. Prog. 39(2) (2019) e12081.

N. K. Mahraur, N. K. Singh, Household LPG Cylinder: Effects of different heads and Impact analysis using ANSYS. J. Phys. Conf. Ser. 1240(1) (2019) 1 – 10.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.