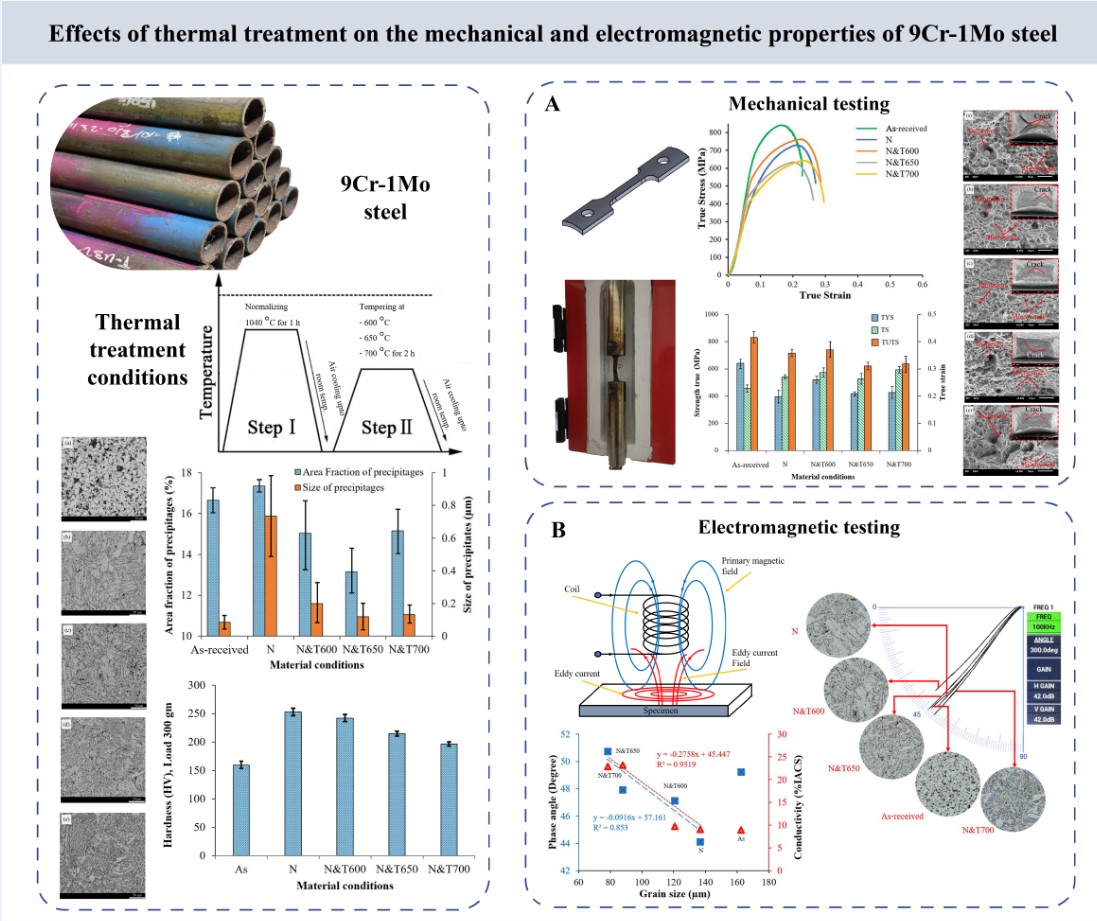

Effects of thermal treatment on the mechanical and electromagnetic properties of 9Cr-1Mo steel

DOI:

https://doi.org/10.55674/jmsae.v12i1.249441Keywords:

9Cr-1Mo steel, Electromagnetic, Static tensile testing, Elevated temperature tensile testing, Eddy currentAbstract

This paper presents the effects of thermal treatment conditions on the mechanical properties of 9Cr-1Mo steel. Each sample was normalized at 1,040 °C for 1 h prior to tempering at different temperatures for 2 hours. Three levels of tempering conditions, 600, 650, and 700 °C, were tested in this study. After treatment, the metallurgical structures of the samples were observed and characterized by optical microscope (OM), scanning electron microscope (SEM), energy dispersive X-ray spectrometer (EDS) and X-ray diffraction (XRD). Hardness and static tensile of the samples at room and elevated temperatures were also measured and analyzed. Non-destructive testing (NDT) associated with the eddy current method was employed to detect the microstructural changes of samples. The results revealed that the lath martensitic structure, lath boundaries, coarse precipitates, and prior austenite grain boundaries were found at grain boundaries and inside the matrix region. The average size of the particle and area fraction of carbide precipitates decreased with tempering temperature increases from 600 − 650 °C. The true yield stress and true ultimate tensile stress decreased while true strain increased when the tempering process was applied after the normalization. In addition, the use of the eddy current method at 100 kHz with proper conductivity could more accurately detect the microstructural changes of 9Cr-1Mo steel specimens than using the phase angle approach. The correlation coefficient of conductivity and true ultimate tensile strength was found to be 0.9459, indicating a high correlation between them.

References

R. Viswanathan, W. Bakker, Materials for ultra-supercritical coal power plants boiler materials: part 1, J. Mater. Eng. Perform. 10 (2001) 81 – 95.

C. Coussment, A. Dhooge, M. de Witte, R. Dobbelaere, E. van der Donckt, High temperature properties of improved 9% Cr steel weldments, Int. J. Press. Vessel. Pip. 45(2) (1991) 163 – 178.

H.B. Sata, G. Amarendra, R. Rajaraman, C.S. Sundar, Microstructural characterization of ferritic/martensitic steel by positron annihilation spectroscopy, J Phys Conf Ser. 443 (2013) 1 – 6.

S. Mannan, S.C. Chetal, B. Raj, S. Bhoje, Selection of Material for Prototype Fast Breeder Reactor, Trans. Indian Inst. Met. 56 (2003) 155 – 178.

F. Masuyama, History of Power Plants and Progress in Heat Resistant Steels, ISIJ Int. 10 (6) (2001) 612 – 625.

M.E. Abd El-Azim, A.M. Nasreldin, G. Zies, A. Klenk, Microstructural instability of a welded joint in P91 steel during creep at 600 °C, Mater. Sci. Technol. 21(7) (2005) 779 – 790.

A. Mitra, J.N. Mohapatra, J. Swaminathan, M. Ghosh, A.K. Panda and R.N. Ghosh, Magnetic evaluation of creep in modified 9Cr-1Mo steel, Scr. Mater. 57(9) (2007) 813 – 816.

F. Sket, K. Dzieciol, A. Borbely, A.R. Kaysser-pyzalla, K. Maile, R. Scheck, Microtomo-graphic investigation of damage in E911 steel after long term creep, Int. J. Mater. Res. 528(1) (2010) 103 – 111.

C. Pandey, M.M. Mahapatra, P. Kumar, N. Saini, Effect of normalization and tempering on microstructure and mechanical properties of V - groove and narrow - groove P91 pipe weldments, Mater. Sci. Eng. A. 685 (2017) 39 – 49.

P. Mohyla, Z. Kubon, R. Cep, I. Samardzic, Evaluation of Creep Properties of Steel P92 and Its Welded Joint, Metalurgija. 53(2) (2014) 175 – 178.

H.K.D.H. Bhadeshia, A. Strang, D.J. Gooch, Ferritic power plant steels: remanent life assessment and approach to equilibrium, Int. Mater. Rev.43 (2013) 45 – 69.

K.S. Chandravathi, K. Laha, K. Bhanu Sankara Rao, S. Mannan, Microstructure and tensile properties of modified 9Cr–1Mo steel (grade 91), Mater. Sci. Technol. 17(5) (2001) 559 – 565.

Y. Jaluria, Chapter One - Heat and Mass Transfer in Materials Processing and Manufacturing, Adv. Heat Transf. 48 (2016) 1 – 94.

R.J. Seher, G. N. Maniar, Analytical-preshadowed extraction replica technique. Metallography, Metallogr. 5(5) (1972) 409 – 414.

S. Jana, Non-destructive in-situ replication metallography, J Mater Process Technol. 49(1-2) (1993) 85 – 114.

K. Mariappan, V. Shankar, R. Sandhy, M.D. Mathew, A.K. Bhaduri, Influence of Prior Fatigue Damage on Tensile Properties of 316L(N) Stainless Steel and Modified 9Cr-1Mo Steel, Metall Mater Trans A Phys Metall Mater Sci. 46 (2014) 989 – 1003.

D.J. Hagemair, Fundamentals of eddy current testing, Amer Society for Nondestructive, (1990) 1 - 92.

C. S. Kim, Nondestructive Evaluation by Reversible Magnetic Permeability of the Residual Life of Ferritic 9Cr Steel Subjected to Creep-Fatigue Damage, Mater Trans. 59 (2017) 316 – 319.

A. Sahebalam, M. Kashefi, S. Kahrobaee, Comparative study of eddy current and Barkhausen noise methods in microstructural assessment of heat treated steel parts, Nondestruct. Test. Evaluation. 29 (2014) 208 – 218.

M. Oka, Y. Tsuchida, T. Yakushiji, M.Enokizono, Fatigue Evaluation for a Ferritic Stainless Steel (SUS430) by the Eddy Current Method Using the Pancake-Type Coil. IEEE Trans. Magn. 46(2) (2010) 540 – 543.

D. Kukla, A. Bałkowiec, P. Grzywna, Evaluation of Microstructural Changes of S235 Steel after Rolling on the Basis of Microscopic Observations and Eddy Current Non-Destructive Method, Adv. Mater. Sci., 14 (2014) 40 – 48.

M. Kashefi, S. Kahrobaee, M.H. Nateq, On the Relationship of Magnetic Response to Microstructure in Cast Iron and Steel Parts, J. Mater. Eng. Perform. 21 (2012) 1520 – 1525.

J. Liu, J. Wilson, M. Strangwood,C. L. Davis, Magnetic characterization of microstructural feature distribution in P9 and T22 steels by major and minor BH loop measurements, J. Magn. Magn. Mater. 401 (2016) 579 – 592.

J. Liu, M. Strangwood, C. L. Davis, A.J. Peyton, Magnetic Evaluation of Microstructure Changes in 9Cr-1Mo and 2.25Cr-1Mo Steels Using Electromagnetic Sensors, Metall Mater Trans A Phys Metall Mater Sci. 44(13) (2013) 5897 – 5909.

F. Abe, 9Cr-1Mo steel, in K. Yagi, G. Merckling, T.-U. Kern, H. Irie, H. Warlimont (Eds.), Landolt-Börnstein - Group VIII Advanced Materials and Technologies 2B (Creep Properties of Heat Resistant Steels and Superalloys), 2004, Vol 2B, pp, 118 – 125.

J. Arndt, K. Haarmann, G. Kottmann, J. C. Vaillant, W. Bendick, F. Deshayes, Thermal Power Plants, Janeza Trdine 9, Rijeka, Croatia, 51000.

ASTM, I A213/A213M − 18: Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes1, West Conshohocken, PA, USA: ASTM International, 2018.

M. Song, C. Sun, Y. Chen, Z. Shang, J. Li, Z. Fan, K. T. Hartwig and X. Zhang, Grain refinement mechanisms and strength-hardness correlation of ultra-fine grained grade 91 steel processed by equal channel angular extrusion, Int. J. Press. Vessel. Pip. 172 (2019) 212 – 219.

N. Saini, C. Pandey, M.M. Mahapatra, Characterization and evaluation of mechanical properties of CSEF P92 steel for varying normalizing temperature, Mater. Sci. Eng. A. 688 (2017) 250 – 261.

D.R. Barbadikar, G.S. Deshmukh, L. Maddi, K. Laha, P. Parameswaran, A.R. Ballal, D.R. Peshwe, R.K. Paretkar, M. Nandagopal, M.D. Mathew, Effect of normalizing and tempering temperatures on microstructure and mechanical properties of P92 steel, Int. J. Press. Vessel. Pip. Vol. 132 (2015) 97 – 105.

N. Saini, C. Pandey, M.M. Mahapatra, R.S. Mulik, On study of effect of varying tempering temperature and notch geometry on fracture surface morphology of P911 (9Cr-1Mo-1W-V-Nb) steel, Eng Fail Anal. 85 (2018) 104 – 115.

N. Saini, C. Pandey, M.M. Mahapatra, R. S. Mulik, Evolution of nano-size precipitates during tempering of 9Cr-1Mo-1W-V-Nb steel and their influence on mechanical properties, Mater. Sci. Eng. A 711 (2018) 37 – 43.

ASTM, I. ASTM E8/E8M-16a: standard test methods for tension testing of metallic materials. West Conshohocken, PA, USA: ASTM International, 2016.

C. Pandey, A. Giri, M.M. Mahapattra, Evolution of phases in P91 steel in various heat treatment conditions and their effect on microstructure stability and mechanical properties, Mater. Sci. Eng. A. 664 (2016) 58 – 74.

E. Ayala, M.A. Roman., Roman, J. Vega, X. Gomez, T. Genez-Acebo, J. Echberria, Delta ferrite formation in 9–12% chromium steel weldments, Mater. Sci. (1998) 633 – 643.

X. Chai, J.C. Bundy, M.A. Amata, C. Zhang, F. Zhang, S. Chen, S. S. Babu, S.Kou, Creep Rupture Performance of Welds of P91 Pipe Steel, Weld J. 94(5) (2015) 145 – 157.

N. Fujita, H.K.D.H. Bhadeshia, Modelling simultaneous alloy carbide sequence in power plant steels, ISIJ Int. 42(7) (2002) 760 – 769.

A. Baltušnikas, R. Levinskas, I. Lukoštūtė, Kinetics of Carbide Formation During Ageing of Pearlitic 12X 1MФ steel, J. Mater. Sci. 13(4) (2007) 286 – 292.

C. Pandey, A. Giri, M.M. Mahapatara, Effect of normalizing temperature on microstructural stability and mechanical properties of creep strength enhanced ferritic P91 steel, Mater. Sci. Eng. A. 657(7) (2016) 173 – 184.

C. Pandey, M.M. Mahapatara, Effect of long-term ageing on the microstructure and mechanical properties of creep strength enhanced ferritic P91 steel, Trans. Indian Inst. Met. 69 (2016) 1657 – 1673.

C. Pandey, M.M. Mahapatara, Effect of soaking temperature and time on microstructure and mechanical properties of P91steel, in: Proceedings of the 23 rd International Conference on Processing and Fabrication of Advanced Materials, IIT Roorkee, India, 2014.

C. Hurtado, C.A. Danon, M. Luppo, P. Bruzzoni, Evolution of minor phase sigma 9Pct Cr steel: effect of tempering temperature and relation with hydrogen trapping, Metall Mater Trans. 46(9) (2015) 3972 – 3988.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.