The effect of excess air on combustion behaviors in vertical pulverized biomass burner

DOI:

https://doi.org/10.55674/ias.v12i2.248089Keywords:

Pulverized biomass, Excess air, BurnerAbstract

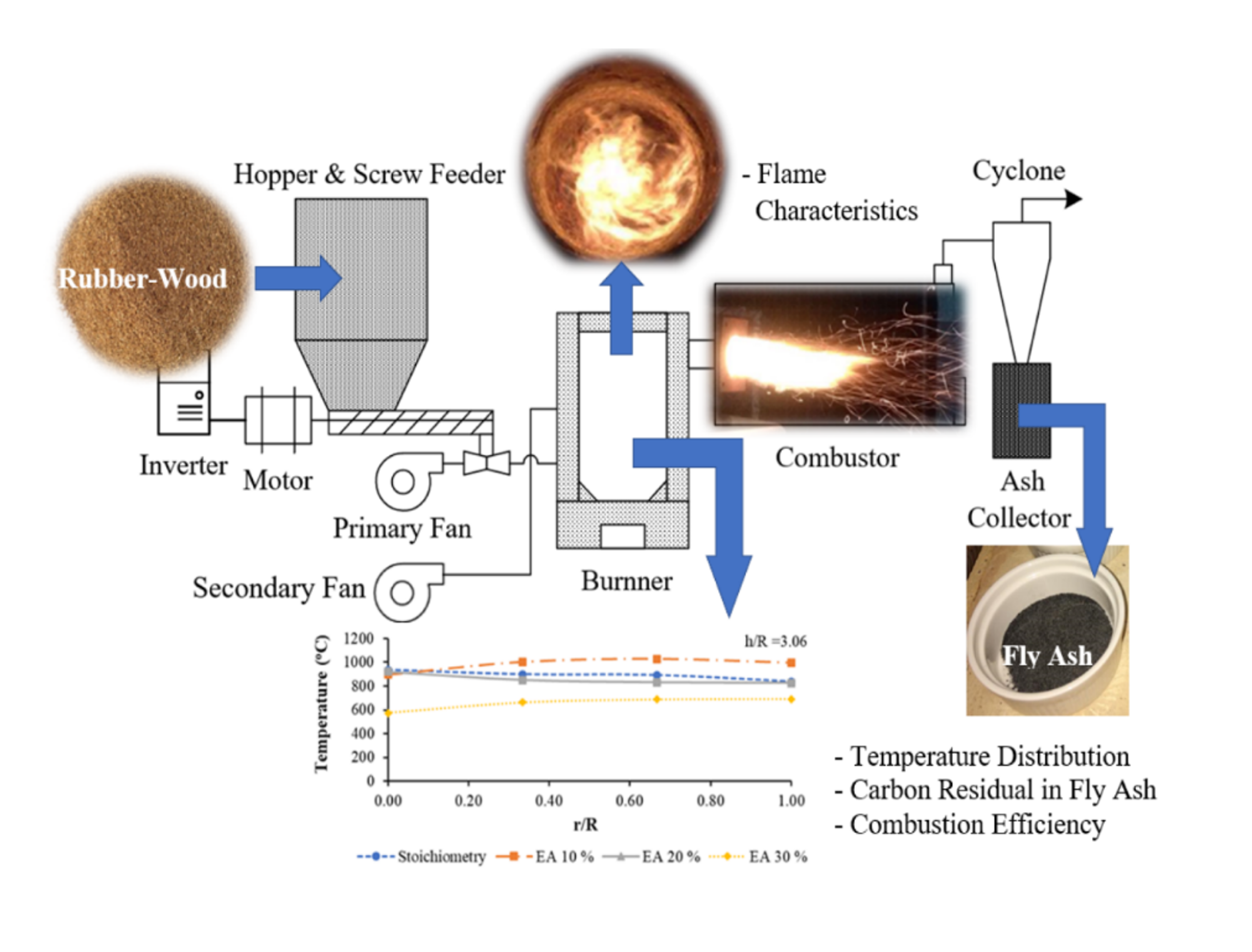

The objectives of this research were to improve biomass burners to be suitable for horizontal fire tube boilers and to study the influence of stoichiometry, 10, 20 and 30% excess air with the air supply divided into two parts, including primary air and secondary air. Rubber wood sawdust was used as the biomass for this experiment. The biomass burners in this experiment had an internal diameter of 30 cm and a chamber height of 70 cm, which stand on the bottom ash bin, comprising combustion with a heating power of 150 kW and a 40:60 percent ratio of primary air to secondary air. The results showed that the burner was able to maintain a constant burning state when the temperature at which the fuel particles were fed into the burner was higher than the devolatilization temperature (400 °C). The introduction of secondary air into the center burner in a three-way rotation resulted in flame characteristics within the burner induced in the internal center arc of the burner by a radial ratio (r /R) of 0.33 – 1. The radial ratio (r/R) of 0.67 showed that the combustion reaction with 10% excess air had a maximum mean temperature distribution inside the burner of 1,000 °C. Combustion at 10% excess air had minimum residual carbon in the fly ash of 38.22% and a maximum combustion efficiency of 89.29%. As a result, such excess air was suitable as a condition used for vertical biomass burners.

References

K. Duanguppama, K. Chaiphet, P. Kraisoda, C. Turakarn, Fuel production from plastic waste with fast pyrolysis, The First National and International Conference of Kalasin University 2019, Kalasin University. 15 – 16 July 2019, 82 – 90.

K. Chaiphet, C. Turakarn, S. Pongskul, K. Duanguppama, Effect of plastic type on the yields and properties of fuel from fast pyrolysis, The 11th Engineering, Science, Technology and Architecture Conference 2020, Nakhon Ratchasima Rajabhat University. 21 August 2020, 1296 – 1302.

C. Turakarn, K. Chaiphet, K. Suvanapa, K. Duanguppama, The effect of pyrolysis temperature on yields and properties of fuel from plastic bag, The 11th Engineering, Science, Technology and Architecture Conference 2020, Nakhon Ratchasima Rajabhat University. 21 August 2020, 566 – 571.

C. Turakarn, K. Duanguppama, K. Chaiphet, A. Mungchu, S. Boothaisong, S. Phokha, The Effect of Plastic Waste Oil from Fast Pyrolysis Process on Lowest Brake Horsepower and Maximum Engine Brake Specific Fuel Consumption, J – REC. 4(2) (2021) 14 – 20.

K. Chaiphet, C. Turakarn, K. Duanguppama, C. Sasen, S. Khamsuwan, P. Promphipha, The product yields and fuel properties from catalytic pyrolysis of plastic bag, J. Mater. Sci. Appl. Energy. 11(1) (2022) 16 – 23.

M. Kusenberg, A. Eschenbacher, M.R. Djokic, A. Zayoud, K. Ragaert, S. De Meester, K.M. Van Geem, Opportunities and challenges for the application of post-consumer plastic waste pyrolysis oils as steam cracker feedstocks: To decontaminate or not to decontaminate?, Waste Manag. 138 (2022) 83 – 115.

B. Freel, R. Graham, Method and apparatus for a circulating bed transport fast pyrolysis reactor system, U.S. Patent No. 5,792,340, Washington, DC., 1998.

A.V. Bridgwater, Upgrading biomass fast pyrolysis liquids, Environ. Prog. Sustainable Energy. 31(2) (2012) 261 – 268.

D. Chen, A. Gao, K. Cen, J. Zhang, X. Cao, Z. Ma, Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin, Energ Convers Manag. 169 (2018) 228 – 237.

T.J. Morgan, A. Youkhana, S.Q. Turn, R. Ogoshi, M. Garcia-Pérez, Review of Biomass Resources and Conversion Technologies for Alternative Jet Fuel Production in Hawai’i and Tropical Regions, Energ Fuel. 33(4) (2019) 2699 – 2762.

Y. Niu, Y. Lv, Y. Lei, S. Liu, Y. Liang, D. Wang, S.e. Hui, Biomass torrefaction: properties, applications, challenges, and economy, Renew Sustain Energ Rev. 115 (2019) 109395.

M.N. Cahyanti, T.R.K.C. Doddapaneni, T. Kikas, Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements, Bioresource Technol. 301 (2020) 122737.

O. Yakaboylu, J. Harinck, K.G. Smit, W. de Jong, Testing the constrained equilibrium method for the modeling of supercritical water gasification of biomass, Fuel Process Tech. 138 (2015) 74 – 85.

D. Barisano, G. Canneto, F. Nanna, E. Alvino, G. Pinto, A. Villone, M. Carnevale, V. Valerio, A. Battafarano, G. Braccio, Steam/oxygen biomass gasification at pilot scale in an internally circulating bubbling fluidized bed reactor, Fuel Process Tech. 141 (2016) 74 – 81.

J. Billaud, S. Valin, M. Peyrot, S. Salvador, Influence of H2O, CO2 and O2 addition on biomass gasification in entrained flow reactor conditions: Experiments and modelling, Fuel. 166 (2016) 166 – 178.

K. Duanguppama, A. Pattiya, Fast pyrolysis of Leucaena leucocepphala in a circulating fluidised bed reactor, 23rd European Biomass Conference and Exhibition 2015, Vienna, Austria. 1 – 4 June 2015, 1206 – 1211.

K. Duanguppama, N. Suwapaet, A. Pattiya, Fast pyrolysis of contaminated sawdust in a circulating fluidised bed reactor, J Anal Appl Pyrol. 118 (2016) 63 – 74.

K. Duanguppama, K. Rueangsan, P. Kraisoda, C. Turakarn, The effect of catalyst on the heating value and energy yield from the fast pyrolysis of leucaena leucocephala, UDRU Sci. & Tech. J. 5(1) (2017) 97 – 111.

A. Garcia–Maraver, J.A. Perez–Jimenez, F. Serrano–Bernardo, M. Zamorano, Determination and comparison of combustion kinetics parameters of agricultural biomass from olive trees, Renew Energ. 83 (2015) 897 – 904.

J. Riaza, J. Gibbins, H. Chalmers, Ignition and combustion of single particles of coal and biomass, Fuel. 202 (2017) 650 – 655.

M.A. Saeed, G.E. Andrews, H.N. Phylaktou, B.M. Gibbs, Flame speed and Kst reactivity data for pulverised corn cobs and peanut shells, J Loss Prev Process Indust. 49 (2017) 880 – 887.

N. Sousa, J.L. Azevedo, Model simplifications on biomass particle combustion, Fuel.184 (2016) 948–956.

P. Laphirattanakul, J. Charoensuk, C. Turakarn, C. Kaewchompoo, N. Suksam, Development of pulverized biomass combustor with a pre–combustion chamber, Energy.208 (2020) 118333.

J. Koppejan, S. Van Loo, The handbook of biomass combustion and co–firing, 1st ed.,Routledge, London, 2007.

R.T. Stephen, An introduction to combustion: concepts and applications, third ed., McGraw–Hill Companies, Incorporated, 2012.

M. Kamal, Parametric study of combined premixed and non–premixed flame coal burner, Fuel.87(8-9) (2008) 1515 –1528.

S. Jugjai, N. Polmart, Enhancement of evaporation and combustion of liquid fuels through porous media, Exp Therm Fluid Sci.27(8) (2003) 901–909.

A. Nishiyama, H. Shimojima, A. Ishikawa, Y. Itaya, S. Kambara, H. Moritomi, S. Mori, Fuel and emissions properties of Stirling engine operated with wood powder, Fuel.86(15) (2007) 2333–2342.

A. Elorf, B. Sarh, Excess air ratio effects on flow and combustion caracteristics of pulverized biomass (olivecake), Case Studies in Thermal Engineering. 13 (2019) 100367.

C. Turakarn, Biomass Burner Development in Industrial Boilers, M.Eng. Mechanical Engineering, King Mongkut’s Institute of Technology Ladkrabang, Bangkok, 2015.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.