Electrochemical analysis study of rare earth element: Lanthanum under the effect of magnetic field and its application as an additive for chrome magneto electrodeposition

DOI:

https://doi.org/10.55674/jmsae.v11i2.244913Keywords:

Lanthanum, Magneto electrodeposition, Linear sweep voltammetry, ChronoamperometryAbstract

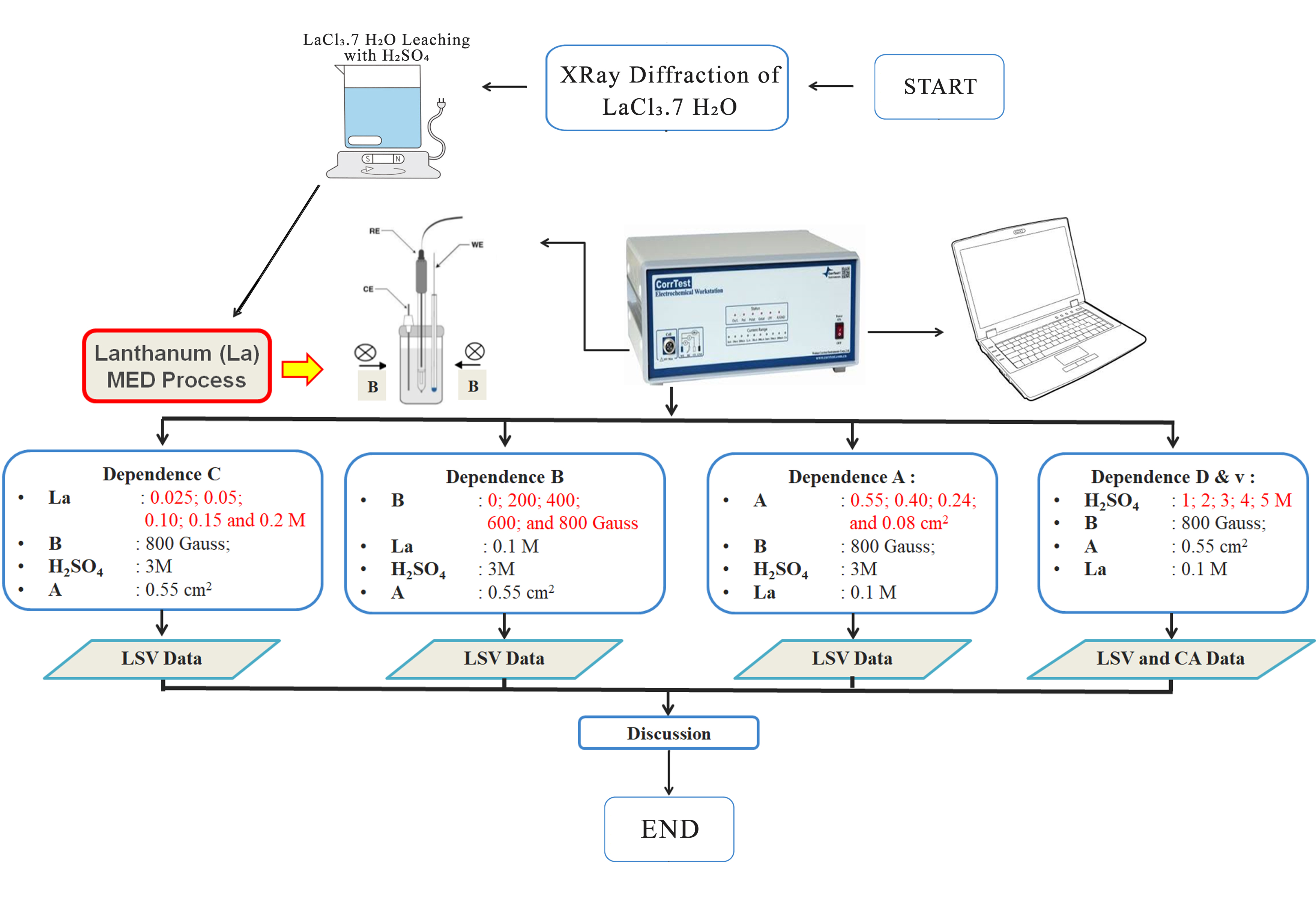

Lanthanum is a rare earth group that is increasingly needed for a variety of applications. In this study, we analyze the effect of magnetic fields on lanthanum electrodeposition. Electrochemical analysis techniques used are linear sweep voltammetry (LSV) and Chronoamperometry (CA). LSV is used to measure the maximum current (limiting current). To determine the maximum current, the result of the LSV must be plotted in a Tafel plot. Tafel generated from LSV is the electrode potential (mV) with the logarithm of the current density (Log iL (A·cm–2)). The diffusion coefficient of the electroactive species was determined using chronoamperometry (CA). The results showed that the effect of increasing the working electrode area (A), magnetic field strength (B), and electroactive concentration (C) gave a certain increase in limiting current. Meanwhile, the addition of solution viscosity (v) and diffusion coefficient (D) will reduce the limiting current value for lanthanum electrodeposition. This study also carried out a chrome-plating process with the addition of lanthanum which was studied previously, it was found that the plating process using magnetic field produced a more uniform; thicker; more compact, and more mass deposit.

References

J. Ignasius, Potential of Rare Earth Metals in Indonesia. Indonesian Ministry of Energy and Mineral Resources, Jakarta, 2019.

R. Herlani, Muljono, S. Widiyati, Mujari, Study the Effect of the Rare Earth Metals Cerium (Ce) and Lanthanum (La) on Thorium Analysis Using the X-Ray Fluorescent Method, Mujari Pusat Teknologi Akselerator dan Proses Bahan, BATAN. (2011) 237 – 248.

Peraturan Menteri Energi dan Sumber Daya Mineral ini mulai berlaku pada tanggal, BN 2018/ NO 595. Indonesia, 2018.

M.H. Uzir, Sudibyo, N. Aziz, Magneto-electro deposition of Tin Dendrites, Surf. Coat. Technol. 264 (2015) 66 – 71

A. Levesque, S. Chouchane, J. Douglade, R. Rehamnia, Chopart, Effect of Natural and Magnetic Convections on the Structure of Electrodeposited Zinc–Nickel Alloy, Appl. Surf. Sci. 255(18) (2009) 8048 – 8053.

K. Tschulik, J.A. Koza, M. Uhlemann, A. Gebert, L. Schultz, Effects of Well-defined Magnetic Field Gradients on the Electrodeposition of Copper and Bismuth, Electrochem. Commun. 11(11) (2009) 2241 – 2244.

J.A. Koza, F. Karnbach, M. Uhlemann, J. McCord, C. Mickel, A. Gebert, S. Baunack, Schultz, Electrocrystallisation of CoFe Alloys Under the Influence of External Homogeneous Magnetic Fields–Properties of Deposited Thin Films, Electrochim. Acta. 55(3) (2010) 819 – 831.

V.G. Levich, Physicochemical Hydrodynamics. Englewood Cliffs, N.J., Prentice-Hall, New Jersey, 1962.

M.T. Fernanda, T.A. Paulo, Electrodeposition of Magnetic CoPd Thin Films Influence of Plating Condition, 28th ECS Meeting, Los Angeles USA. 16 October 2005, 89 – 101.

Sudibyo, A.S. Handoko, U. Herlina, N. Aziz, Y.A. Sukma, Application of artificial neural network model to predict limiting current for cobalt magneto-electrodeposition, AIP Conf. Proc. 2232(1) (2020) 020009.

S. Sandhaya, R.R. Vaishaka, A.C. Hedge, Magnetoelectrodeposition of Sn-Ni alloy coating for better corrosion protection, IJCEP. 2(1) (2016) 29 – 42.

T.R.N. Mhı́ocháin, G. Hinds, A. Martin, E. Chang, A. Lai, L. Costiner, J.M. Coey, Influence of the magnetic field and gravity on the morphology of zinc fractal electrodeposit, Electrochim. Acta. 49(27) (2004) 4813 – 4829.

Sudibyo, Modeling of Limiting Current ang Growth Fractal for Electrodepotition Under Magnetic Field Influence, M.Sc. Universiti Sains Malaysia, Penang, 2010.

S. Taruli, Development of Limiting Current Semi-Empiric Equation for Vanadium Under the Effect of a Magnetic Field Thesis, Sultan Ageng Tirtayasa University, Banten, 2020.

N.A. Lubis, The influence of liquid viscosity on falling time by falling ball method, Fisitek. 2(2) (2018) 26 – 32.

D.Wang, Y. Cheng, H. Jin, J. Zhang, J. Gao, Influence of LaCl3 addition on microstructure and properties of nickel-electroplating coating, J. Rare Earths. 31(2) (2012) 209 – 214.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.