The product yields and fuel properties from catalytic pyrolysis of plastic bag

DOI:

https://doi.org/10.55674/jmsae.v11i1.244075Keywords:

Fuel, Catalytic Pyrolysis, Plastic BagAbstract

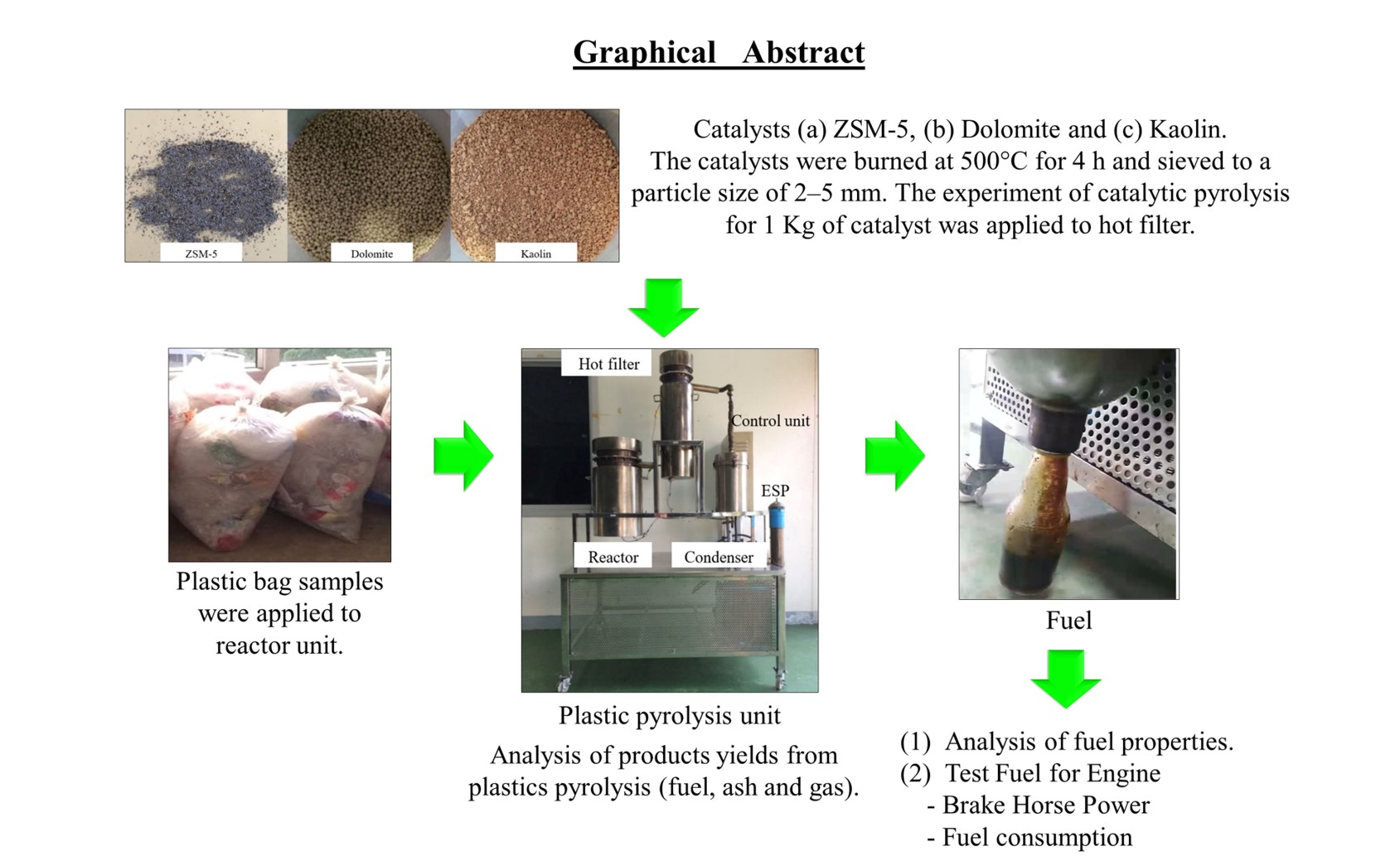

The objective of this research was to study product yields and fuel properties. The fuel was then tested for use in the engine to study brake horsepower (BHP) and fuel consumption. The experiment began with pyrolysis of plastic bags in a fixed bed reactor at 500 °C with three catalysts: ZSM-5, dolomite, and kaolin. The analysis of fuel properties consists of higher heating value (HHV), density, viscosity, and flash point - fire point. For test engine of this research used 12 HP Kubota brand single-cylinder diesel engine, tested at a speed of 1,500 rpm, with a fuel temperature of 40 °C for determine the brake horsepower and fuel consumption. The results showed that non-catalytic, the highest yields of fuel were 65.70 wt%. This fuel has a (HHV) of 36.70 MJ Kg–1 and a fire point up to 133.30 °C. Results of engine tested show that it has a minimum BHP of 9.20 HP and a maximum fuel consumption of 1.10 Kg HP–1 h–1. When catalytic pyrolysis of plastics with ZSM-5 catalyst, the fuel yields was reduced to 57.80 wt%. However, the alumina mixed in this catalyst allows the fuel maximum HHV of 43.20 MJ Kg–1, flammable at 28.70 °C. Results of engine tested show that it has a maximum BHP of 11.90 HP and a minimum fuel consumption of 0.40 Kg HP–1 h–1. The catalyst dolomite and kaolin increase the calorific value, reduce the viscosity, easily flammable, but overall, not as good as ZSM-5. It can be concluded that keolin catalysts are suitable for use in pyrolysis requiring increased fuel yield. The ZSM-5 catalyst was suitable for improving fuel quality. Therefore, this research should be continued with plastic pyrolysis using catalysts to improve the quality of the fuel for long-term engine testing.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Journal of Materials Science and Applied Energy

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.