Morphological and Optical Studies of Silica Powders from Waste-Materials by Milling Process for Light-Harvesting Applications

DOI:

https://doi.org/10.55674/ias.v10i3.243929Keywords:

Light scattering particles, Milling process, Silica powder, Waste materialAbstract

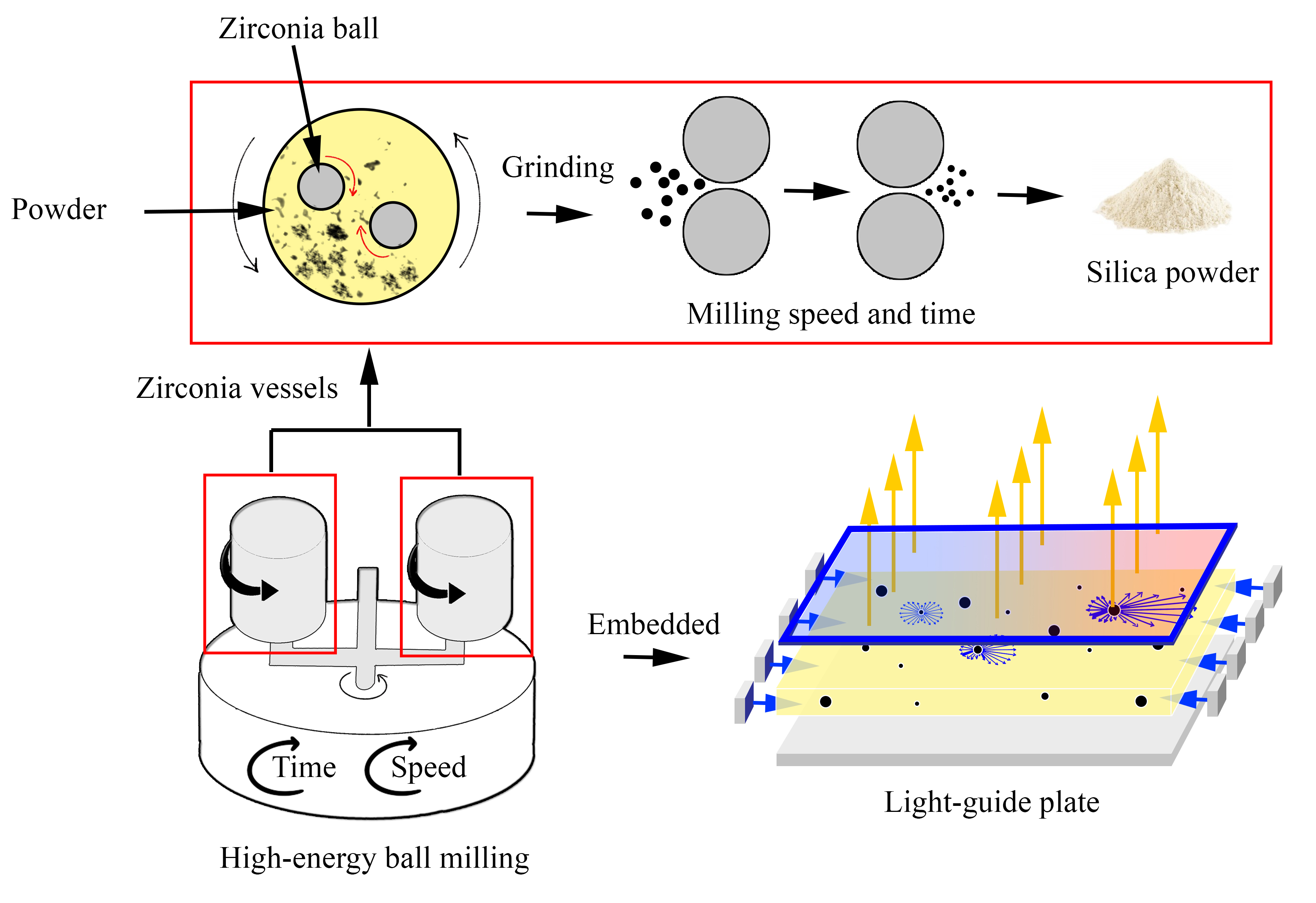

This study focuses on the synthesis process and characterization of silica powders from wasted material obtained by milling process in which mechanical force is applied to material until it

becomes silica powders with uniform distribution in their size. Effects of milling process parameters including milling speed and milling time on structural, morphological, and optical properties of the prepared powders are investigated by SEM technique and particle size analysis. Two steps of the ball milling process were conducted to further reduce the particle size of the powder. The uniform size distribution in the range of lower than 1 mm was achieved by two milling steps at milling speed 300 rpm for 30 min. Moreover, the increase of milling speed and time results to the agglomeration of fine particles forming the cluster of particles. Furthermore, the light scattering characteristic of the milled silica powders is examined in terms of size-related scattering behavior which is meaningful for light-harvesting applications including a light-guide plate with embedded light scatterers.