Heating Performance of Indium Tin Oxide Transparent Heating Element

DOI:

https://doi.org/10.55674/ias.v10i3.243920Keywords:

Electrical property, Heating element, Indium tin oxide, Thermal performanceAbstract

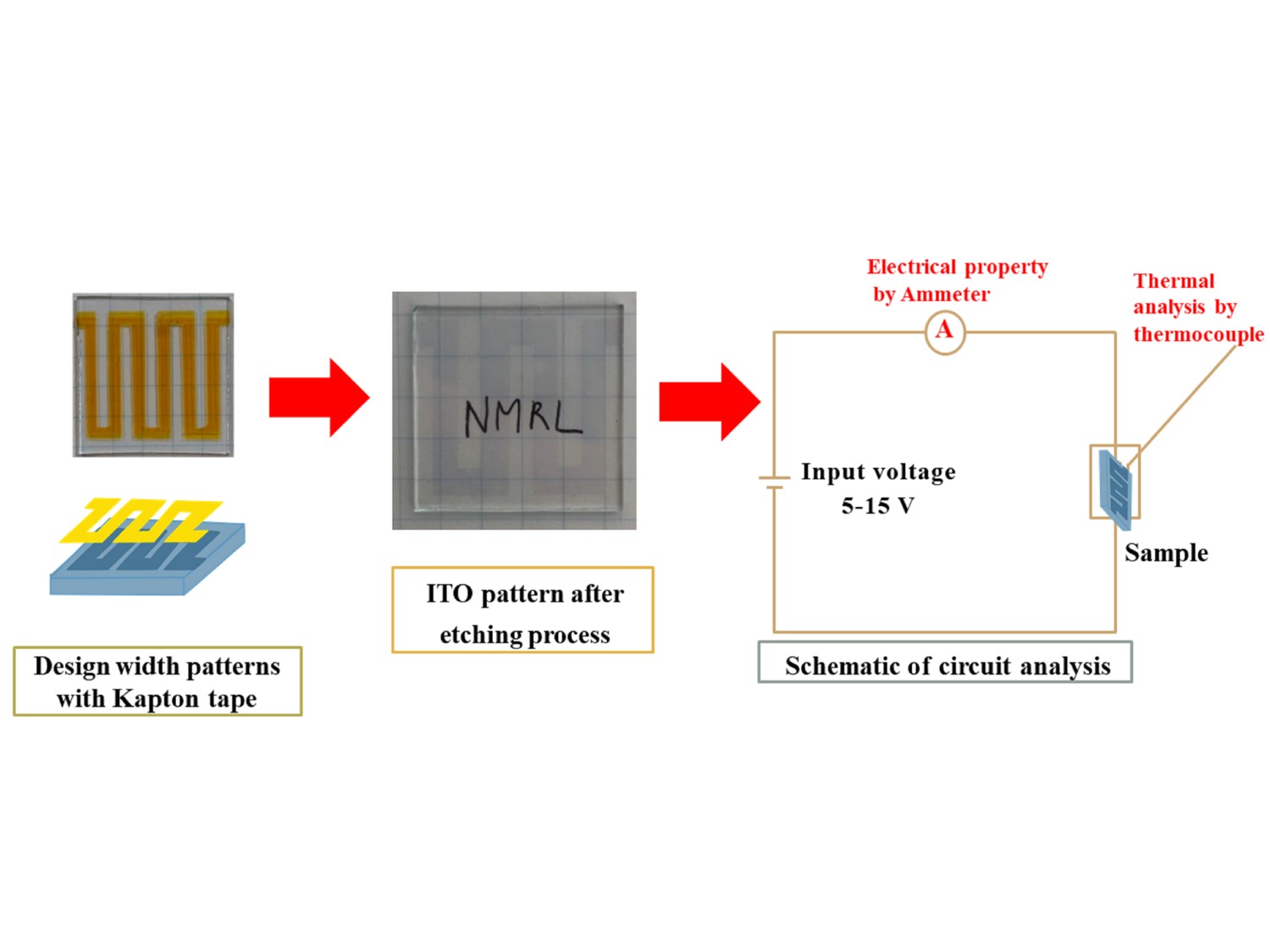

Indium tin oxide (ITO) is one of transparent conducting oxide material which is widely used in electronic industries. The objective of this research is to study thermal performance of ITO heating element stripe fabricated with various sizes and widths. The pattern was designated and fabricated by the acid etching process using aqua-regia whose ratio of hydrochloric acid to nitric acid is fixed at 3:1. Three different widths of 4 mm, 5 mm and 6 mm were designated and patterned. In heating performance testing, various voltages were directly supplied to the elements leading to the elevating temperature as a function of time. It was found that the optimized pattern with width of 6 mm performed excellent electrical heating temperature up to 110 °C at bias voltage of 15 V. The rising and falling time constant of ITO heating elements at 6 mm were also determined as 59.70 s and 68.61 s.