Optimization of Electrometal - Electrowinning Cobalt Process from the Slag of Nickel Pig Iron (NPI)

DOI:

https://doi.org/10.55674/ias.v10i2.242741Keywords:

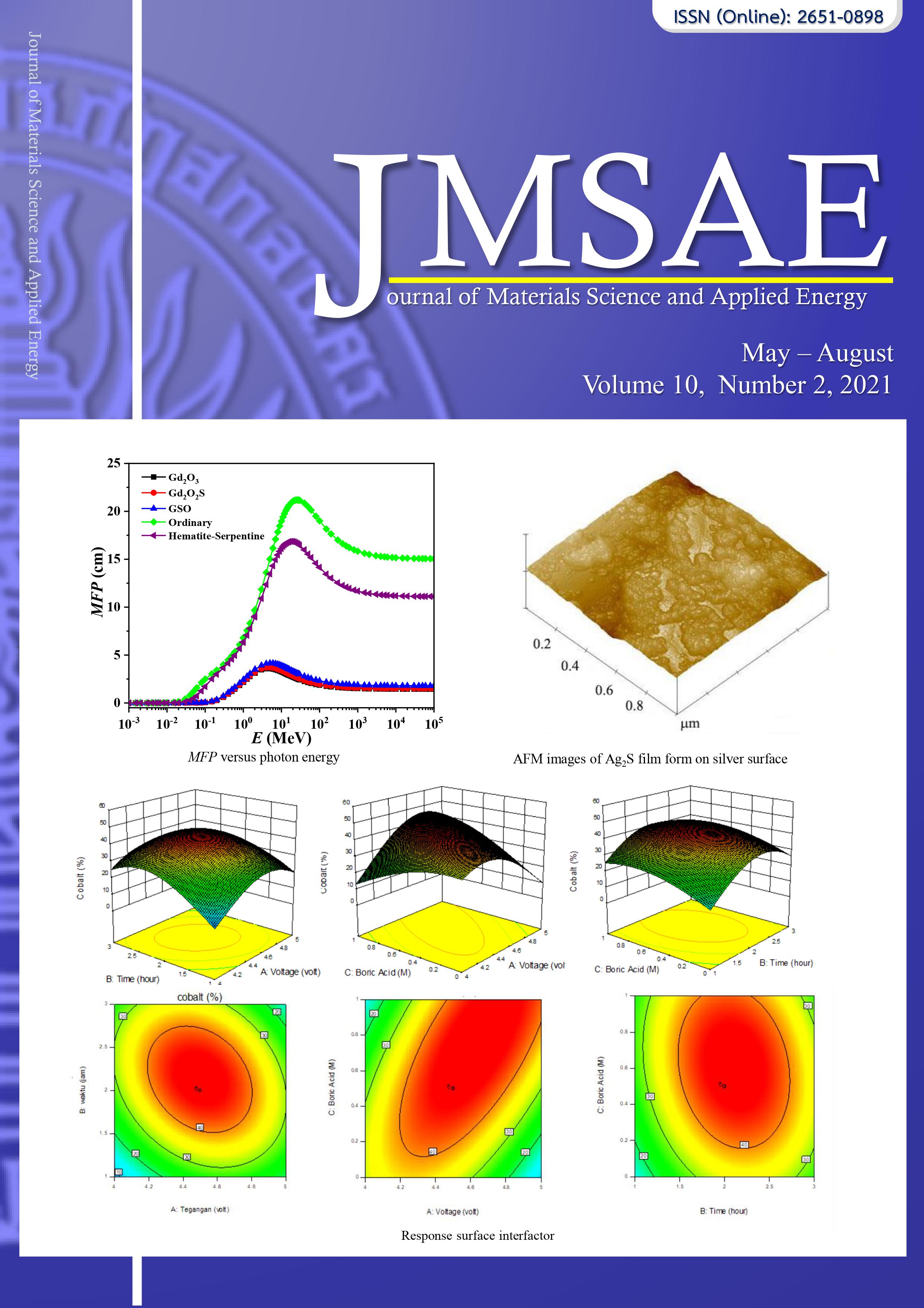

Cobalt Electrowinning, Cobalt Extraction, Slag of Nickel Pig Iron, Response Surface Methods, Cyanex 22Abstract

Slag from the manufacturing of nickel pig iron (NPI) from laterite soil was still containing 823.70 ppm of cobalt. In this research, the separation process was carried out from slag NPI by using the Response Surface Method (RSM). This method was to determine the optimum conditional process of Electrometal Electrowinning (EMEW) and get an equation model to obtain the correlation between a variable and understand the most significant interfactor interaction. This research was conducted using three parameters, consisting of duration of operation, potential voltage, and variable of boric acid. The first step in electro-metal electrowinning was leach the slag using acetic acid and extracted it with versatic acid 10 and cyanex 272 respectively. The organic phase from this extraction was stripped by 6 M sulphuric acid and obtained aqueous phase at pH 5.50 with the highest cobalt content. The best condition of electro-metal electrowinning was obtained at 4.50 V, 2 h, and 0.50 M of boric acid with 45.82 % of cobalt recovery. Based on the statistic analysis using software, time was an individual factor which gives the most significant influence to the percent of generating electrowinning, while the most significant interfactor interaction based on the sequential model sum of squares, lack of fit test, model statistic, and analysis of variance (ANOVA) analysis was quadratic model with R2 of 0.95.