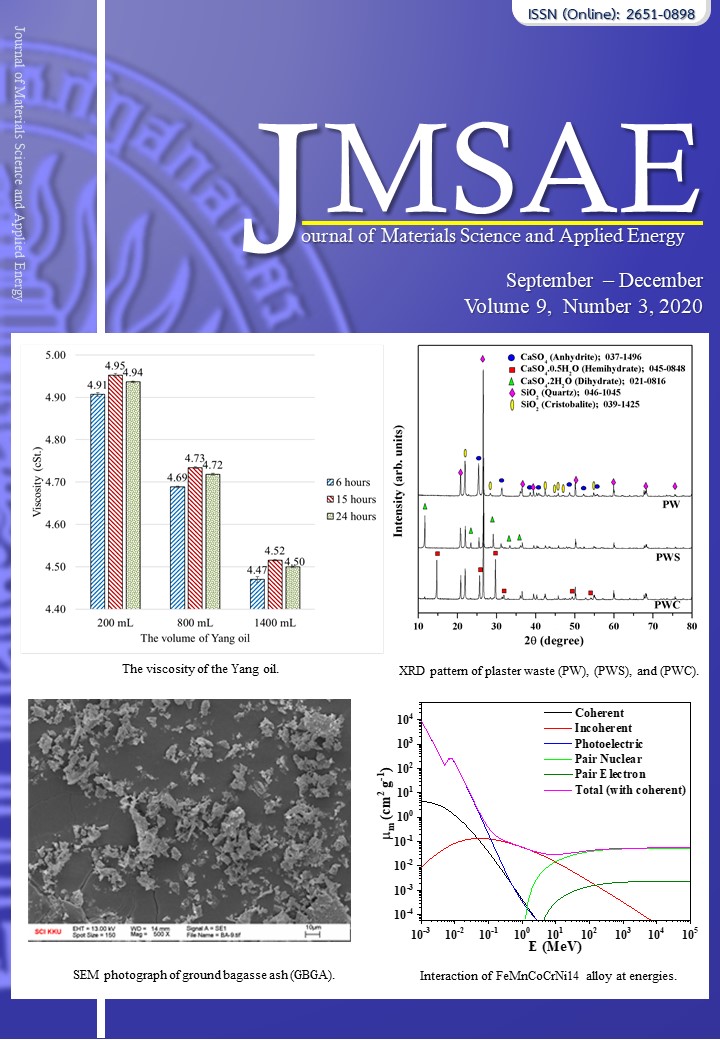

Recycle Plaster Waste from Jewelry Casting Process

DOI:

https://doi.org/10.55674/ias.v9i3.239923Keywords:

Recycle, Plaster waste, Jewelry casting plasterAbstract

In this work, the plaster waste from the jewelry casting process has been studied hydration with soaking in water at 20 weeks. The XRD and FTIR confirm the structural phase of the plaster waste is calcium sulphate anhydrite (CaSO4). The plaster waste after soaking in water 20 weeks present, calcium sulphate dihydrate (CaSO4 × 2H2O) and plaster waste after calcine at 120 °C present calcium sulphate hemihydrate (CaSO4 × 2H2O). We can recycle plaster waste from the jewelry casting process by soaking in water at 20 weeks and calcining with rotary dryer 2 h at 120 °C. The plaster waste will have flow and setting time close to standard with water and plaster waste in ratio 50:100. The product can make with plater waste, but it still does not have enough qualities for delicate work.