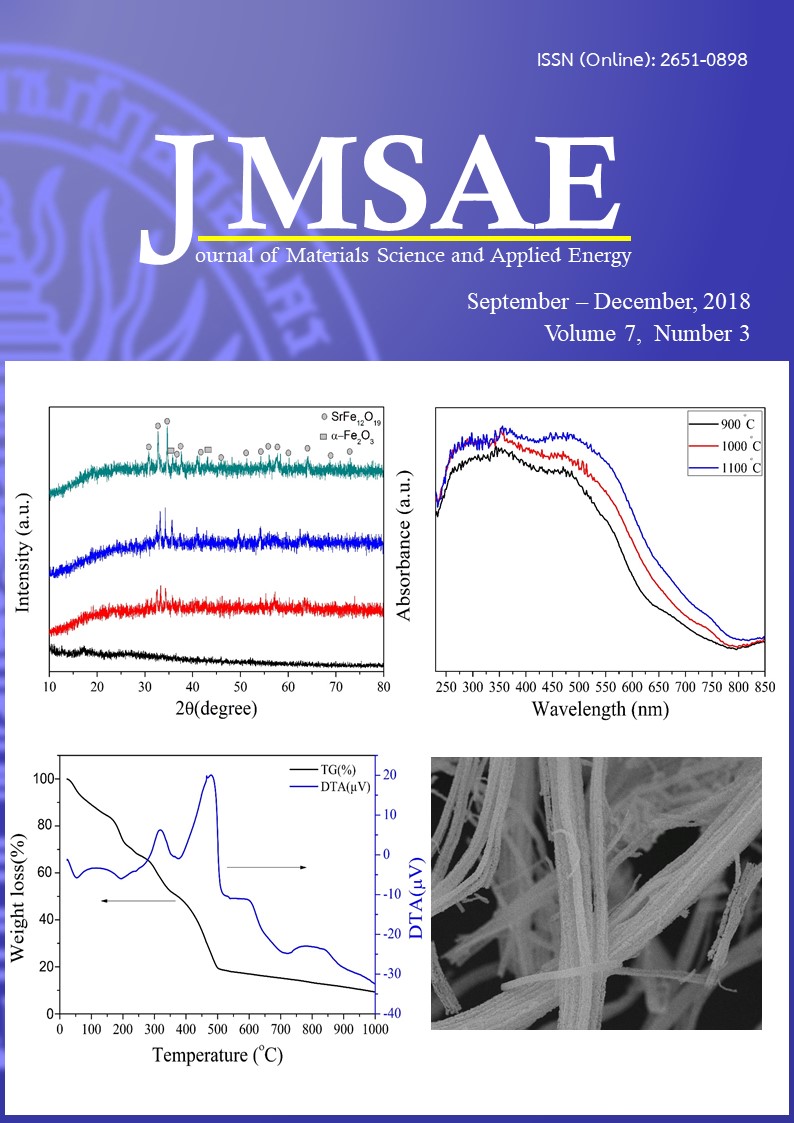

Influence of Molybdenum Disulfide (MoS2) Catalyst on Carbon from Sugarcane Bagasse Via Hydrothermal Carbonization for Jatropha Oil Residue Upgrading

DOI:

https://doi.org/10.55674/ias.v7i3.123349Keywords:

Molybdenum disulfide, Hydrothermal carbonization, Sugarcane bagasse, PyrolysisAbstract

Molybdenum disulfide (MoS2) catalyst has been successfully synthesized for carbon support from lignocellulosic in sugarcane bagasse using hydrothermal carbonization and calcination techniques. The hydrothermal carbonization of lignocellulosic material into carbon support was studied between 160 to 200 °C for 24 h. The MoS2 precursor is prepared by mixing thiourea and ammonium molybdate tetrahydrate then impregnate on carbon support. Surface area and carbon content from lignocellulosic structure as hemicellulose and cellulose were improved at high temperature via hydrothermal carbonization and calcination. The hydrodeoxygenation reaction in molybdenum disulfide catalytic upgrading was studied oxygenated compounds in jatropha oil residue using pyrolyzer gas chromatography mass spectroscopy (Py-GC/MS). It showed that the molybdenum disulfide on carbon support from sugarcane bagasse prepared at 200 ºC for 24 h can reduce oxygenated compounds in jatropha oil residue.