Development of an Autonomous Component Testing System with Reliability Improvement Using Computer Vision and Machine Learning

Main Article Content

Abstract

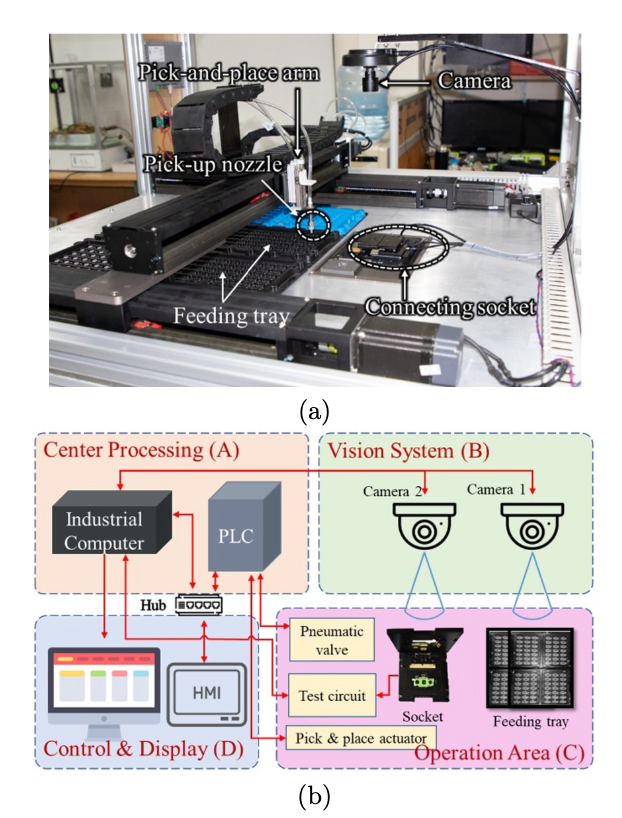

This study evaluated computer vision-based models, including Histogram Analysis, Logistic Regression, Sift-SVM, and Deep learning models, in an autonomous testing system developed for smartphone camera modules. System performance was assessed in a practical factory setting with workers operating the system, and metrics such as processing time, sensitivity, specificity, accuracy, and defect rate were evaluated. Based on the results, the Sift-SVM model demonstrated the greatest potential for enhancing the reliability of the system with a processing time of 0.01578 seconds, a sensitivity of 99.811%, and a reduction in the failure rate to 1888 PPM. The study findings suggest that Sift-SVM has the potential to be practically applied in the industry, thus improving the speed and accuracy of automatic defect detection in manufacturing and reducing the defect rate.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

References

Y. Chen, X. Peng, L. Kong, G. Dong, A. Remani, and R. Leach, “Defect inspection technologies for additive manufacturing,” International Journal of Extreme Manufacturing, vol. 3, no. 2, p. 22002, 2021.

Z. Ren, F. Fang, N. Yan, and Y. Wu, “State of the art in defect detection based on machine vision,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 9, no. 2, pp. 661–691, 2022.

N. N. S. A. Rahman, N. M. Saad, A. R. Abdullah, and N. Ahmat, “A review of vision based defect detection using image processing techniques for beverage manufacturing industry,” Jurnal Teknologi, vol. 81, no. 3, pp. 33–47, 2019.

C. Vedang and S. Brian, “A Comparative Study of Machine Vision Based Methods for Fault Detection in an Automated Assembly Machine,” Procedia Manufacturing, vol. 1, pp. 416–428, 2015.

Z. Chen, J. Deng, Q. Zhu, H. Wang, and Y. Chen, “A Systematic Review of Machine-Vision-Based Leather Surface Defect Inspection,” Electronics (Basel), vol. 11, no. 15, 2022.

S. Qi, J. Yang, and Z. Zhong, “A Review on Industrial Surface Defect Detection Based on Deep Learning Technology,” in Proceedings of the 2020 3rd International Conference on Machine Learning and Machine Intelligence, in MLMI ’20. Association for Computing Machinery, pp. 24–30, 2020.

K. Christian, G. Kristina, K. Varun, A. Burcu, and F. Paul, “A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure,” Advanced Engineering Informatics, vol. 29, no. 2, pp. 196–210, 2015.

C. Szegedy et al., “Going deeper with convolutions,” in 2015 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), pp. 1–9, 2015.

P. V. Arun, “A CNN based Hybrid approach towards automatic image registration,” Geodesy and Cartography, vol. 39, no. 3, pp. 121–128, 2013.

A. Krizhevsky, I. Sutskever, and G. E. Hinton, “ImageNet classification with deep convolutional neural networks,” Communications of the ACM, vol. 60, no. 6, pp. 84–90, 2017.

K. Simonyan and A. Zisserman, “Very deep convolutional networks for large-scale image recognition,” arXiv preprint arXiv:1409.1556, 2014.

P. Jiang, D. Ergu, F. Liu, Y. Cai, and B. Ma, “A Review of Yolo algorithm developments,” Procedia Computer Science, vol. 199, pp. 1066–1073, 2022.

F. Sultana, A. Sufian, and P. Dutta, “A review of object detection models based on convolutional neural network,” Intelligent computing: image processing based applications, pp. 1–16, 2020.

W. Zhiqiang and L. Jun, “A review of object detection based on convolutional neural network,” in 2017 36th Chinese control conference (CCC), pp. 11104–11109, 2017.

H. Wang and D. Hu, “Comparison of SVM and LS-SVM for regression,” in 2005 International conference on neural networks and brain, pp. 279–283, 2005.

S. V. M. Vishwanathan and M. N. Murty, “SSVM: a simple SVM algorithm,” in Proceedings of the 2002 International Joint Conference on Neural Networks. IJCNN’02 (Cat. No. 02CH37290), pp. 2393–2398, 2002.

Q. Li and X. Wang, “Image classification based on SIFT and SVM,” in 2018 IEEE/ACIS 17th International Conference on Computer and Information Science (ICIS), pp. 762–765, 2018.

Y. Liu, S. Zhou, and Q. Chen, “Discriminative deep belief networks for visual data classification,” Pattern Recognit, vol. 44, no. 10–11, pp. 2287–2296, 2011.

Y. Hua, J. Guo, and H. Zhao, “Deep belief networks and deep learning,” in Proceedings of 2015 International Conference on Intelligent Computing and Internet of Things, pp. 1–4, 2015.

M. Robotyshyn, M. Sharkadi, and M. Malyar, “Surface defect detection based on deep learning approach,” in IntSol Workshops, pp. 32–44, 2021.

M. Baygin, M. Karakose, A. Sarimaden, and E. Akin, “Machine vision based defect detection approach using image processing,” in 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), pp. 1–5, 2017.

S. Panagiotis, P. Alexios, and P. Dimitris, “A vision-based system for real-time defect detection: a rubber compound part case study,” Procedia CIRP, vol. 93, pp. 1230–1235, 2020.

S. Barua, F. Liou, J. Newkirk, and T. Sparks, “Vision-based defect detection in laser metal deposition process,” Rapid Prototyping Journal, vol. 20, no. 1, pp. 77–85, 2014.

J. P. Yun, S. Choi, and S. W. Kim, “Vision-based defect detection of scale-covered steel billet surfaces,” Optical Engineering, vol. 48, no. 3, p. 37205, 2009.

Y. Li, H. Wang, L. M. Dang, H.-K. Song, and H. Moon, “Vision-Based Defect Inspection and Condition Assessment for Sewer Pipes: A Comprehensive Survey,” Sensors, vol. 22, no. 7, p. 2722, 2022.

Y. He, K. Song, Q. Meng, and Y. Yan, “An End-to-End Steel Surface Defect Detection Approach via Fusing Multiple Hierarchical Features,” in IEEE Transactions on Instrumentation and Measurement, vol. 69, no. 4, pp. 1493–1504, 2020.

J. Zhong, Z. Liu, Z. Han, Y. Han, and W. Zhang, “A CNN-Based Defect Inspection Method for Catenary Split Pins in High-Speed Railway,” in IEEE Transactions on Instrumentation and Measurement, vol. 68, no. 8, pp. 2849–2860, 2019.

R. Shanmugamani, M. Sadique, and B. Ramamoorthy, “Detection and classification of surface defects of gun barrels using computer vision and machine learning,” Measurement, vol. 60, pp. 222–230, 2015.

H.-D. Lin and H.-L. Chen, “Automated visual fault inspection of optical elements using machine vision technologies,” Journal of Applied Engineering Science, vol. 16, no. 4, pp. 447–453, 2018.

C ̧. Aytekin, Y. Rezaeitabar, S. Dogru, and I. Ulusoy, “Railway Fastener Inspection by Real-Time Machine Vision,” inIEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 45, no. 7, pp. 1101–1107, 2015.

J. Yang, S. Li, Z. Wang, H. Dong, J. Wang, and S. Tang, “Using deep learning to detect defects in manufacturing: a comprehensive survey and current challenges,” Materials, vol. 13, no. 24, p. 5755, 2020.

T. Wang, Y. Chen, M. Qiao, and H. Snoussi, “A fast and robust convolutional neural network-based defect detection model in product quality control,” The International Journal of Advanced Manufacturing Technology, vol. 94, pp. 3465–3471, 2018.

Y. Yang et al., “A High-Performance Deep Learning Algorithm for the Automated Optical Inspection of Laser Welding,” Applied Sciences, vol. 10, no. 3, p. 933, 2020.

H.-A. Phan et al., “Development of a Vision System to Enhance the Reliability of the Pick-andPlace Robot for Autonomous Testing of Camera Module used in Smartphones,” in 2021 International Conference on Engineering and Emerging Technologies (ICEET), pp. 1–6, 2021.

H. Wang, “A Review of Six Sigma Approach: Methodology, Implementation and Future Research,” in 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, pp. 1–4, 2008.

E. Atmaca and S. S. Girenes, “Lean Six Sigma methodology and application,” Qual Quant, vol. 47, pp. 2107–2127, 2013.

C. Bradley and Y. S. Wong, “Surface texture indicators of tool wear-a machine vision approach,” The International Journal of Advanced Manufacturing Technology, vol. 17, pp. 435–443, 2001.

D. W. Hosmer Jr, S. Lemeshow, and R. X. Sturdivant, Applied logistic regression, vol. 398. John Wiley & Sons, 2013.

B. C. Ko, K.-H. Cheong, and J.-Y. Nam, “Fire detection based on vision sensor and support vector machines,” Fire Safety Journal, vol. 44, no. 3, pp. 322–329, 2009.

E. Hortal et al., “SVM-based brain–machine interface for controlling a robot arm through four mental tasks,” Neurocomputing, vol. 151, pp. 116–121, 2015.

M. N. Murty, R. Raghava, M. N. Murty, and R. Raghava, “Kernel-based SVM,” Support vector machines and perceptrons: learning, optimization, classification, and application to social networks, pp. 57–67, 2016.

Z. Zhang, “Derivation of backpropagation in convolutional neural network (cnn),” University of Tennessee, Knoxville, TN, vol. 22, p. 23, 2016.

A. Mikolajczyk and M. Grochowski, “Data augmentation for improving deep learning in image classification problem,” in 2018 international interdisciplinary PhD workshop (IIPhDW), pp. 117–122, 2018.

S. Akhtar, M. Hanif, and H. Malih, “Automatic Urine Sediment Detection and Classification Based on YoloV8,” in International Conference on Computational Science and Its Applications, pp. 269–279, 2023.

T.-Y. Lin et al., “Microsoft coco: Common objects in context,” in Computer Vision–ECCV 2014: 13th European Conference, Zurich, Switzerland, September 6-12, 2014, Proceedings, Part V 13, pp. 740–755, 2014.