Wastewater Treatments for Textile Industry by Electrocoagulation Process

Keywords:

Wastewater treatment, textile industry, electrocoagulationAbstract

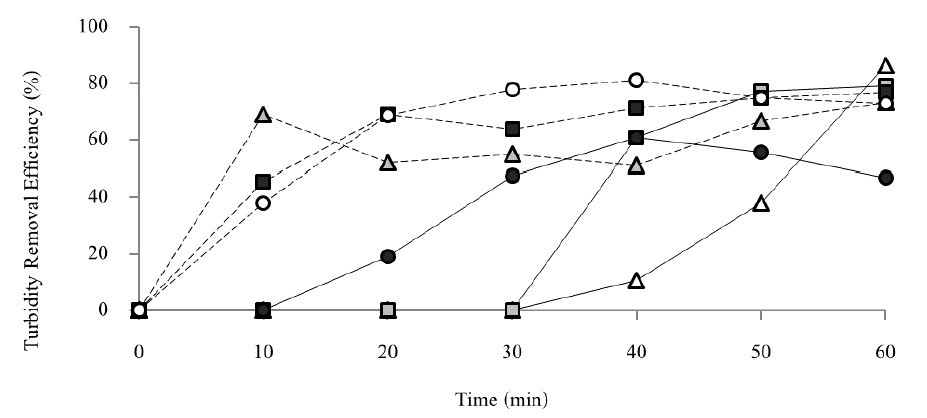

The objective of this research was to study the wastewater treatment for textile industry by electrocoagulation process with synthetic wastewater. The experimental conditions including the initial pH of 7 and 10, the current densities of 0.01, 0.02 and 0.03 A/cm2 with the reaction time from 10 to 60 min. The experimental results revealed that the initial pH of 10, the current density of 0.02 A/cm2 and the reaction time of 20 min were the optimum conditions, resulting in the color, turbidity, and chemical oxygen demand (COD) removal efficiencies of 92.6%, 69.1%, and 89.1%, respectively. While the initial pH of 7, the current density of 0.01 A/cm2 and the reaction time of 40 min were the optimum conditions, resulting in the color, turbidity, and chemical oxygen demand (COD) removal efficiencies of 90.0%, 10.7%, and 92.6%, respectively. The operational costs of initial pH of 10 and pH of 7 were 58.0 bath/m3 and 94.1 bath/m3, respectively. The study indicated that electrocoagulation process at an initial pH of 7 and 10 followed the second-order kinetics. It was found that the activated sludge (AS) system was capable to treat the real textile wastewater better than the electrocoagulation in terms of higher turbidity and COD removal efficiency. Nevertheless, the results suggested that the activated sludge system followed by the electrocoagulation increases the color removal efficiency of the textile industrial wastewater. It can be the alternative wastewater treatment for textile industry.

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2022 The Journal of Applied Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.