Product development of massaman flavored sangyod rice (Oryza sativa L.) spread

Keywords:

Spread, Sangyod Rice, Pregelatinized, Twin drum dryerAbstract

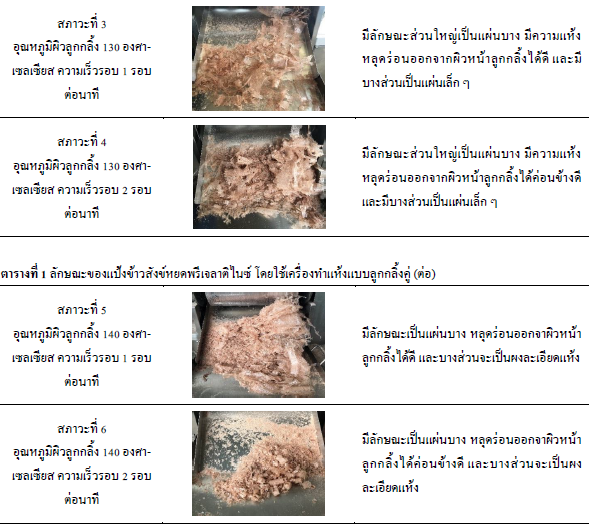

The objective of this research was to investigate the optimum conditions for producing Sangyod pregelatinized rice flour by using a twin drum dryer. This study explored factors, namely: temperature levels of a twin drum dryer adjusted into three levels: 120, 130 and 140 degrees Celsius and the rotational speed adjusted into 2 levels: 1 and 2 rpm. Factorial CRD was used as research design to study the optimal recipe of Massaman Flavored Sangyod Rice Spread. The content of Sangyod pregelatinized rice flour solution was adjusted to be 30% and 40% with 20, 25% and 30% of Massaman curry paste and 10 and 20% of fresh butter. Later, the physical, chemical and consumer acceptance were tested. The testing results indicated that the optimum conditions for producing Sangyod pregelatinized rice flour were a twin drum dryer’s temperature of 140 degrees Celsius with 1 rpm. Under these conditions, obtained Sangyod pregelatinized rice flour were slipped off the surface of the dryer very well with low final viscosity and recovery values. The obtained spread products were more easily applied than pregelatinized flours under other conditions. Furthermore, the optimal recipe of Massaman Flavored Sangyod Rice Spread was the ingredients of 30% Sangyod pregelatinized rice flour solution, 20% Massaman curry paste and 10% fresh butter content. There were no statistically significant differences in the application value (p≤0.05) between the obtained product and the peanut butter product (control) with 3.91 gram of dietary fiber and antioxidant by DPPH of 45.18 mg / eq (Trolox). When consumer acceptance was tested, it was found that the overall preference was at a moderate level.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 The Journal of Applied Science

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.