Effect of temperature and times by hydrothermal carbonization process from sawdust and bagasse for carbon materials supporter

Keywords:

hydrothermal carbonization, biomass, sawdust, bagasse, carbon supporterAbstract

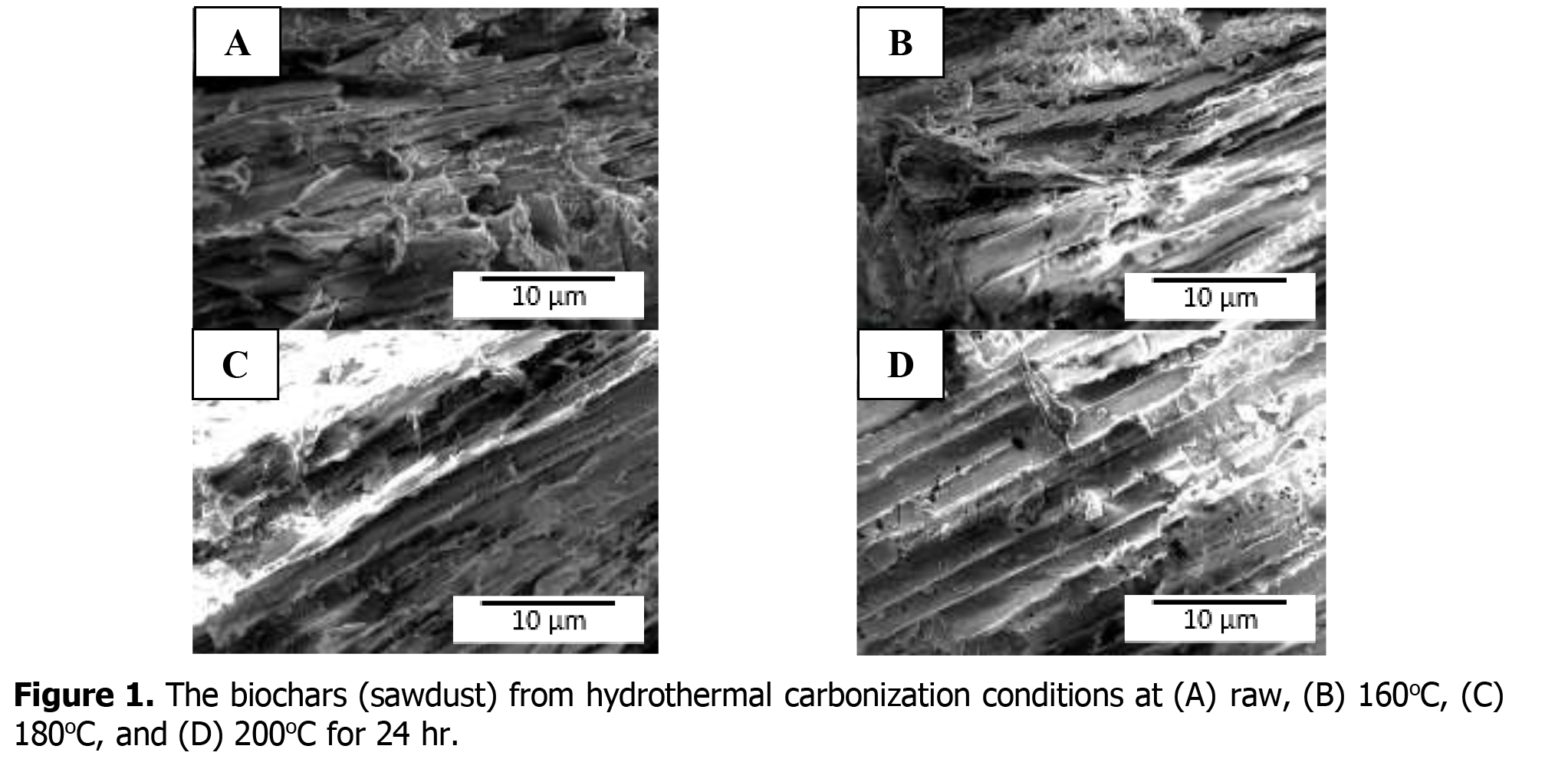

Carbon supporter from biomass has been fabricated by hydrothermal carbonization due to this process changes the structure of lignocellulose including cellulose, hemicellulose and lignin. The applications from carbon support are gaining in importance due to decreasing supply of fossil fuels and growing environmental concerns. Hydrothermal carbonization process was used to upgrade biomass such as sawdust and bagasse varying temperature at 160 to 200 oC and varying times at 4 to 24 hr with deionized water 120 ml and 60 ml, respectively. The biochars from sawdust and bagasse under hydrothermal carbonization conditions were characterized by Fourier transform infrared spectroscopy (FT-IR). It showed that the most hydroxyl group from this samples was decreased due to cellulose and hemicellulose from biochars were decomposed over than 200oC. The Biochars yield from sawdust and bagasse by hydrothermal carbonization conditions was determined from weight loss after hydrothermal carbonization process, which is Biochars yield were decreased with increasing hydrothermal carbonization temperature because lignocellulose was decomposed at high temperature and time. The morphology of Biochars were investigated by scanning electron microscope (SEM). It represented the porous structure was inflated to increasing hydrothermal carbonization temperature.