Effect of Na2SiO3 and Na2CO3 on hydration properties of dicalcium silicate prepared from black rice husk ash

Keywords:

dicalcium silicate, belite, black rice husk ashAbstract

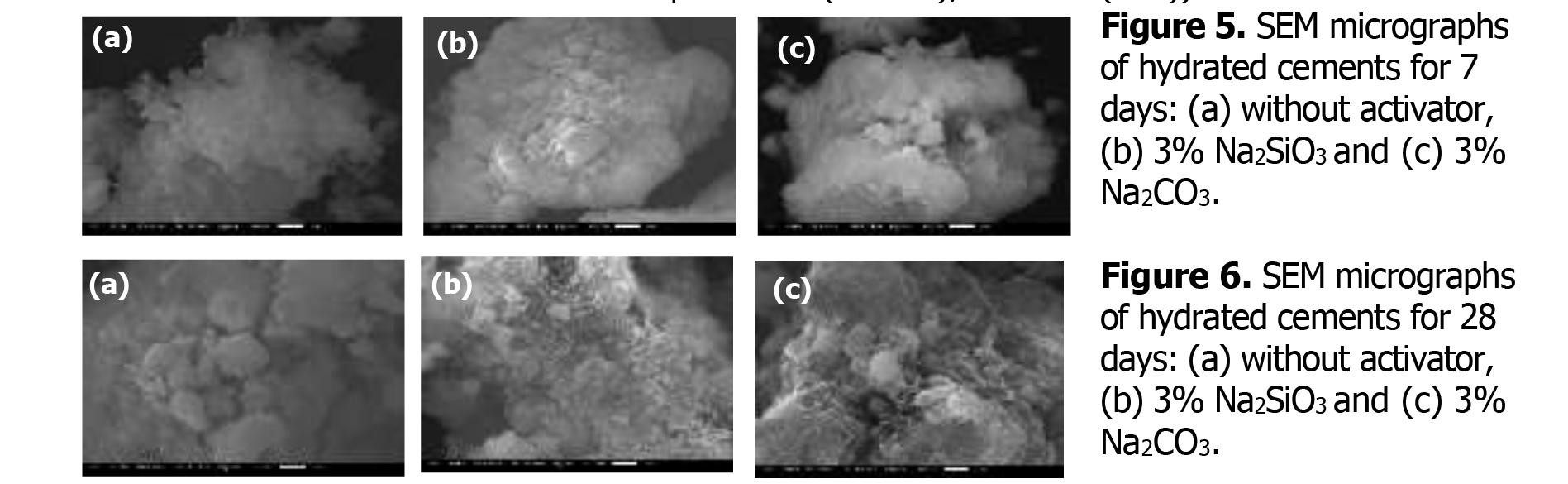

This research aims to investigating the effects of sodium silicate (Na2SiO3) and sodium carbonate (Na2CO3) on the hydration properties of dicalcium silicate prepared from black rice husk ash (BRHA). BRHA is a waste residue from rice milling plant. The major composition and crystalline phase of SiO2 were determined by X-ray fluorescence (XRF) and X-ray diffraction (XRD), respectively. The SiO2 content of BRHA was 93.7% and therefore was used as silica source for the synthesis of dicalcium silicate by firing with CaCO3 at 1100 ºC for 1 hr. XRD results revealed that β-dicalcium silicate or Larnite is the major phase formed. This indicated that BRHA is a potential source of silica and can be used in the as-received from for the synthesis of dicalcium silicate. The obtained dicalcium silicate was reacted with water. The hydration reaction of dicalcium silicate was activated using Na2SiO3 and Na2CO3 at the level of 1, 2 and 3 wt%. The changes in the properties of the hydrated cement products were monitored by several techniques such as X-ray diffraction (XRD), gravimetry/differential thermal analysis (TG/DTA), and Compressive strength. Results showed that the 1% of Na2SiO3 is suitable activator in this work. It's gave the amounts of Ca(OH)2 of 41.91% at 28 days of hydration and highest amorphous CSH gel was present. Moreover, the compressive strength development of hydrated cement with 1% of Na2SiO3 is higher than without activator. Results found that the optimal 1% of Na2SiO3 gave the compressive strength of 154 kg/cm2 at 28 days.