Ethanol production from cellulosic cassava waste

Keywords:

acetic acid, cassava waste, cellulase, fermentationAbstract

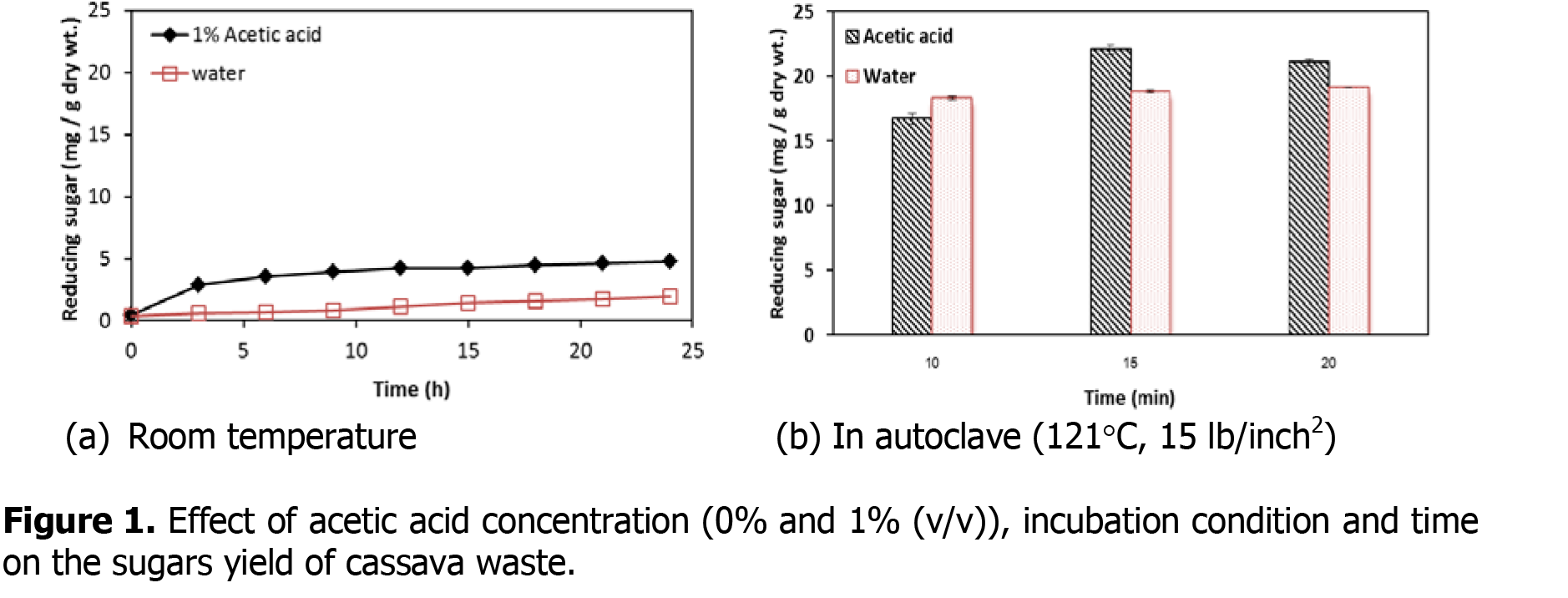

Cassava cellulosic waste obtained from starch processing was utilized in this work for bio-ethanol production. The 10% (w/v) of cassava waste was pretreated with either water or 1% (v/v) acetic acid and steam treated by autoclaving at 121 °C under pressure of 15 pound/inch2 for 15 min. After neutralization of the acid-autoclaved pretreated waste with 2% (w/v) ,the mixture was hydrolyzed further by using 3% or 6% (w/w) cellulase for sugar production. It appeared that the optimum hydrolysis condition was 1% (v/v) acetic acid and 6% (w/w) enzyme (shaking at 50 °C, 150 rpm for 96 h), which gave the maximum sugar yield of 199.82 ± 0.27 mg/g dried cellulosic waste. A total of 515.39 ± 0.48 mg ethanol/g dried cellulosic waste was obtained from 9% (w/v) of Saccharomyces cerevisiae in 7-days fermentation at room temperature. This indicates that cassava wastes actually could be used as substrate for biochemical production, such as fuels, organic acids and etc. In addition, the pretreatment method using dilute acetic acid and steam is environmentally friendly and not complex.