Effect of temper bead in carbon steel with shielded metal arc welding process

Keywords:

Temper beadAbstract

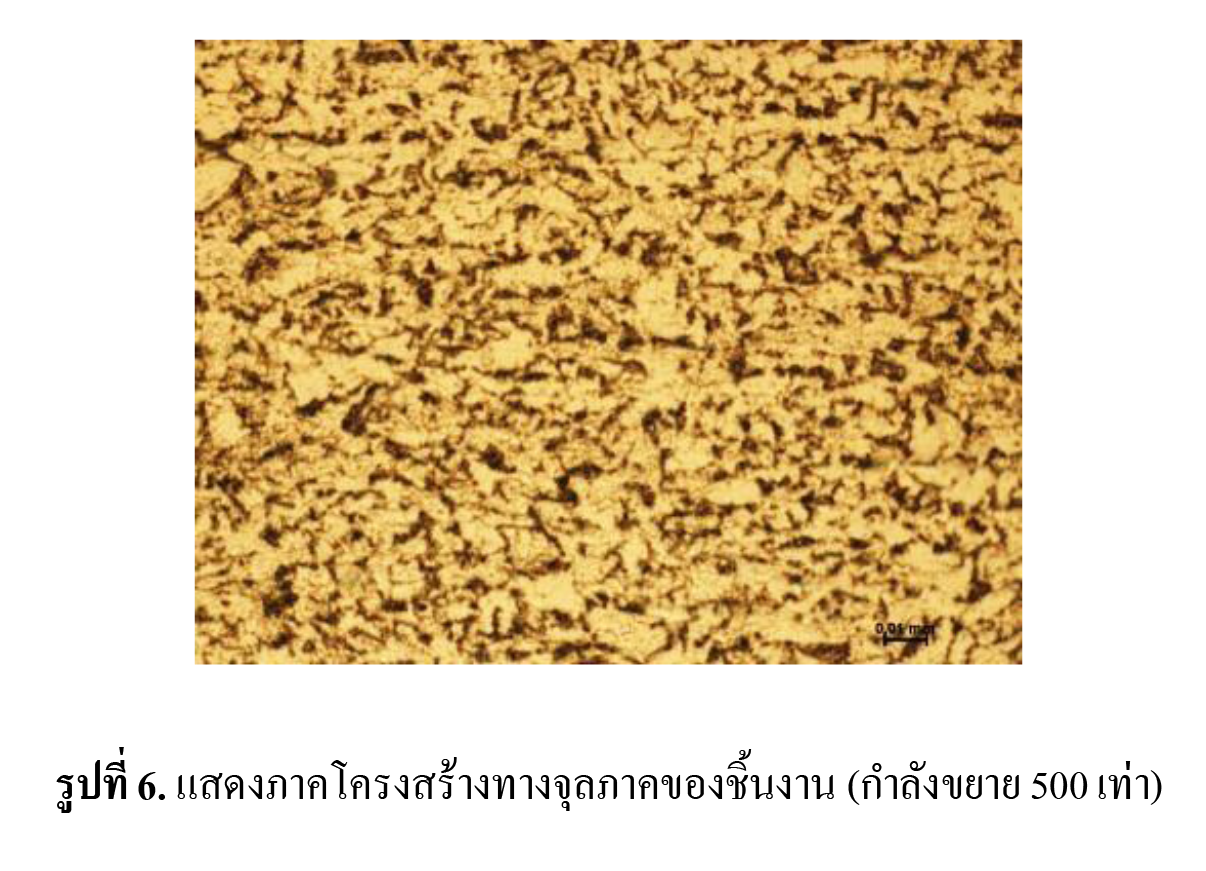

A temper bead welding of carbon steel using a shielded metal arc welding (SMAW) process was performed to study a microstructure and hardness of the weld metal. A material use in this experiment was ASTM A36 carbon steel plate that was 50 millimeters in width, 150 millimeters in length and 5 millimeters in thickness. The welding electrode was AWS A5.1 E7016. The experiment was divided into 2 parts. Firstly, the welding bead overlaps distances effect on the weld property with the welding current of 90-110 amperes was investigated. Secondly, the effect of the welding layers on the weld property with 6 welding layers and the welding current of 120 amperes were investigated. The experiment results such as macrostructure, microstructure, and hardness of the weld metal were collected and analyzed. The experimental result found that the microstructure of the heat affected zone (HAZ) showed the variation characteristic and grains shape was rougher when compared to the fusion area that showed a finer grains shape. The microstructure of the tempered area was modified and showed a decrease of the hardness when compared to the base metal and HAZ. The comparative study of the hardness of pre- and post- tempered found that the hardness of the tempered weld metal was decreased in weld layers. The increase of the weld overlap distance and the weld layer strongly affected to decrease the weld hardness.