Loss reduction of metal contamination in sour cream - tuna spread product

Keywords:

sour cream - tuna spread, metal scrap from steel cans, steel rust, can opener, loss reductionAbstract

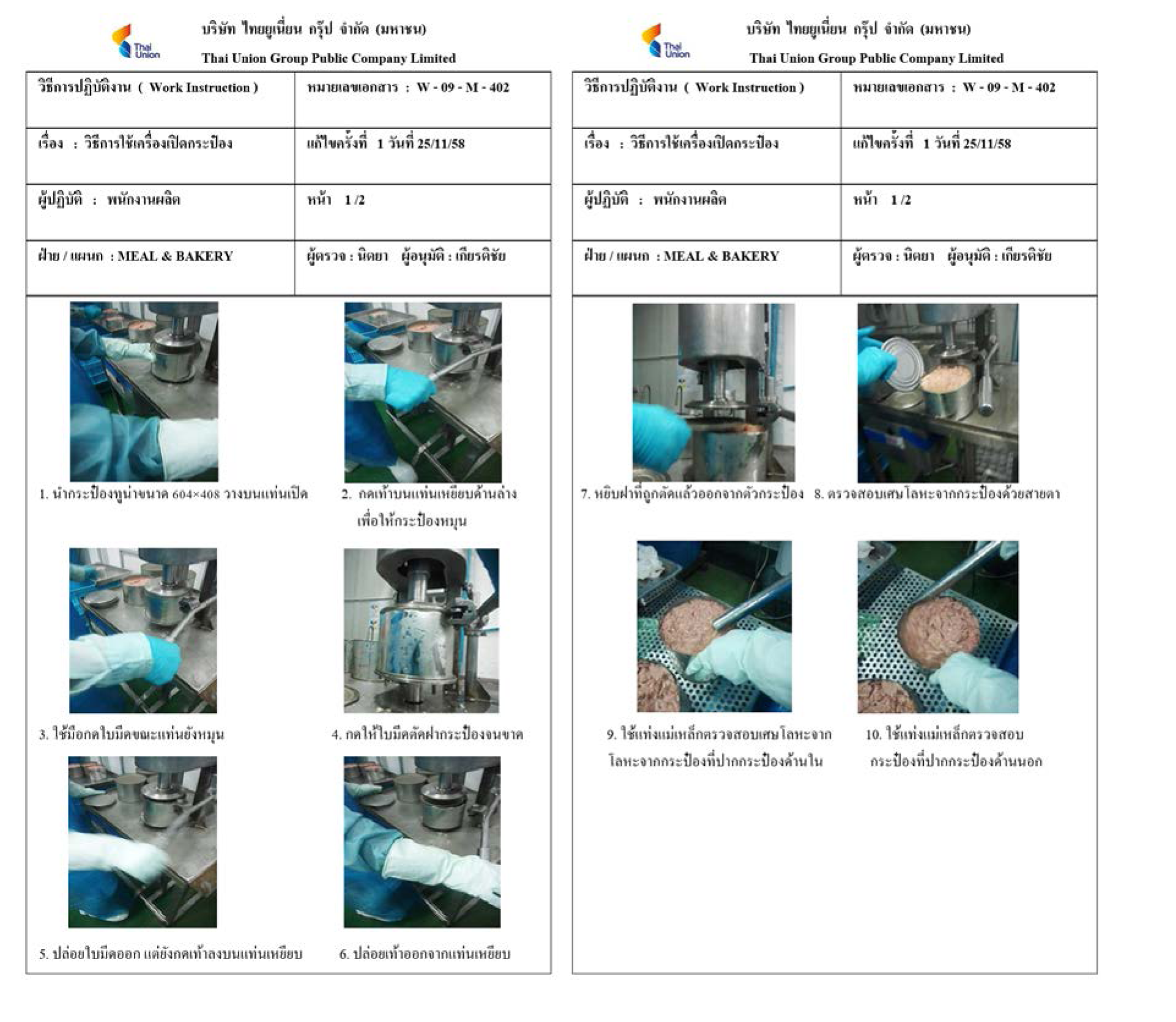

The study of sour cream - tuna spread production indicated the problem of metal contamination in final products detected after passing through the metal detector. Two types of metal were found; metal scrap from steel cans and steel rust. The objective of the project was to decrease the metal contamination to zero waste (0 %). The main cause of metal scrap contamination came from the can opener which lacked of sharpness and had loosened blade cover resulting to inefficient cutting in a single round. Lack of manual for can – opener led to inconsistent usage. Changing blade and the material in the locking blade to stainless steel and adjusting the lever blade resulted to 0 % for the contaminated scrap metal from cans. Preparation of can opening instruction for standard usage could reduce the required number of employees and costs for waste management totally around 153,000 Baht/year. The rust problem found in the final product was mainly from inappropriate process before mixing the tuna mixture. Tuna inspection was improved into 2 steps: using the magnetic bars rolled on tuna and passing through the metal detector. The results showed that stainless steel was not found in the final product after the improvement (zero waste) for the management. Cost reduction was equivalent to 13,000 Baht/year. The improvement also helped increasing the customer reliability and enhanced the production efficiency.